Flexible corrugated pipe with a broach (or probe) or without it is an elastic hollow channel. Its characteristics allow communications in remote and most difficult places without the need for fittings and elbows. The main materials for the production of flexible corrugated pipes are polymers (polypropylene, low-pressure polyethylene, polyvinyl chloride) and stainless steel (unannealed and annealed).

Content

- 1 Annealed Stainless Steel Corrugated Pipe

- 2 Scope and advantages of corrugated steel pipes

- 3 Technical Specifications of Steel Corrugated Pipe

- 4 The use of flexible pipes made of polymer with a broach

- 5 The main types of corrugated tubes with a probe

- 6 Technical Parameters of Polymer Flexible Tubes with or without a Probe

Annealed Stainless Steel Corrugated Pipe

Corrugated steel pipe is a technological and universal material for the installation of piping systems for various purposes. The raw material for its production is stainless steel tape (grade SUS (AISI) 304). After passing through the molding machines, a cylindrical billet is obtained, which is welded automatically.

Note! Welding occurs in the presence of special gases that prevent the burning of alloy metals.

Then the steel corrugation is heated to high temperatures, and then cooled. If this step is present in the process, then an annealed pipe is obtained.

The annealing process gives the product the best strength characteristics, namely:

- plastic;

- better form retention;

- the ability to perform a large number of bends / bends without fracture and deformation.

There are no external differences between the annealed corrugated pipe and the unannealed one. A protective polyethylene shell may be present on the product, which protects the pipe from undesirable effects of aggressive environments.

Scope and advantages of corrugated steel pipes

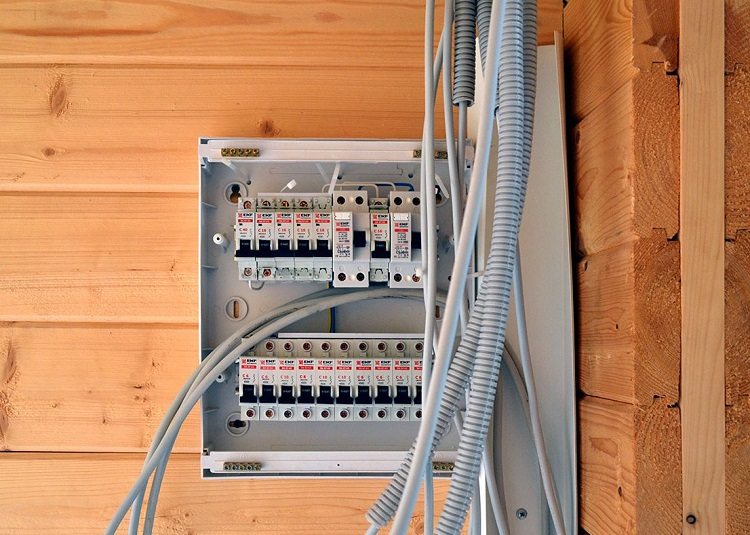

Annealed corrugated pipe can be used in water supply systems (cold and hot), heating, gas supply, air conditioning, for strapping boilers and tanks, arranging a warm floor, automatic fire extinguishing. It is also used as a protective sheath for electrical wiring.

The water supply from such pipes does not need special cleaning and is ready for operation immediately after installation. The design of the product allows you to easily and quickly connect any gas-consuming equipment to a gas source. During installation, special tools and welding are not used, but fitting have a dielectric gasket. Fluoroplastic, silicone or other polymer o-rings may be present in the connecting elements.

The corrugated structure smoothes out linear tension, so the system is resistant to water hammer, pressure drop and temperature. Products are characterized by low noise and low weight.

When laying in a wall or floor, it is necessary to insulate the corrugated pipe with a protective sheath to avoid electrolytic corrosion. Grounding will help eliminate electromechanical corrosion.

Technical Specifications of Steel Corrugated Pipe

Annealed stainless steel flexible pipe is available with diameters of 3.2; 2.5; 2.0; 1.8; 1.5; 1.2 cm. It withstands a maximum pressure of 5 MPa, and the destructive pressure at 20 ° C is 21 MPa. Pipes have low resistance to mechanical damage. For this reason, with an open installation in places where there is a possibility of strong impacts, a protective shell will be required.

Stainless steel corrugated pipe It has a high heat transfer coefficient. If you do not isolate it, then a lot of heat will be lost during transportation of the medium. This point is important when using corrugated pipes for heating and hot water supply.

Note! Since the roughness coefficient of such products is 0.008, the system will not silt or overgrow during operation.

For a heating system or hot water supply, steel corrugated pipes are covered with heat-insulating materials

Their release is made in bays up to 50 m. It is possible to bend flexible corrugated stainless steel pipes with your hands without risk of narrowing the lumen or damaging it.

Table 1

| Index | Size, cm | unit of measurement | ||||

| 1,2 | 1,5 | 2,0 | 2,5 | 3,2 | ||

| External diameter | 1,62 | 1,79 | 2,52 | 3,15 | 3,76 | cm |

| Inner diameter | 1,25 | 1,45 | 2,12 | 2,65 | 3,2 | cm |

| Pipe wall thickness | 0,3 | mm | ||||

| Bay length | 600 | 500 | 300 | 200 | dm | |

| Corrugation Pitch | 0,451 | 0,476 | 0,5 | 0,526 | 0,56 | see |

| Number of pipe folds per 1 m | ≥20 | ≥19 | ≥18 | ≥17 | PC | |

| Plastic shell thickness | 0,3 | mm | ||||

| Manual bending radius | ≥30 | ≥40 | ≥50 | ≥65 | mm | |

| Working temperature | -50…+150 | ° C | ||||

| Short-term maximum temperature | 150 | ° C | ||||

| Maximum pressure at maximum temperature | 15 | bar | ||||

| Hydraulic pressure | up to 60 | kg * s / cm2 | ||||

The use of flexible pipes made of polymer with a broach

Corrugated pipe can be made of polymer raw materials, which does not spread combustion. Such a product is intended for laying in it television, computer, electrical, telephone networks that operate on direct or alternating current at a voltage of not more than 1 kV and are made with insulated cables, wires or cords.

During installation, the number of network connections is significantly reduced, which increases the tightness of the system, the speed of installation work, and also reduces the consumption of fittings.

The polymers used are self-extinguishing. When a power wire ignites, the fire will not spread further. This complies with fire safety requirements.

The pipe can be equipped with a broach (or probe) and is characterized by high ring stiffness, chemical resistance to aggressive environments. There are single and double-walled corrugated pipes with a broach. Their outer wall is made of high-pressure polyethylene corrugated, the inner wall is smooth of low-pressure polyethylene.

Many types of electrical pipes are equipped with a probe for the convenience of placing the cable inside them

A protective flexible pipe with a broach does not rub the wire while it is drawn inward by the probe. To connect corrugated pipes with the same diameter, a transparent sleeve is used, which may have a stop inside.

The main types of corrugated tubes with a probe

Flexible pipes with a broach are made from different polymers:

- polyvinyl chloride (PVC);

- low pressure polyethylene (HDPE);

- polypropylene (PP);

- composite two-layer materials.

Protective corrugated pipe made of polypropylene can be used for laying electrical networks in ceiling systems, wall blocks, floors made of non-combustible material. Polypropylene for a corrugated tube with a probe is characterized by good resistance to any temperature fluctuations, moisture.

A pipe with a broach of self-extinguishing PVC is characterized by increased resistance to acids, oils, alkalis, solvents, and moisture. It is more durable and is absolutely harmless to health, because it does not emit toxic compounds during operation.

Note! There are light products intended for installation inside buildings, and heavy products - for pouring concrete or cement screed.

Corrugated HDPE pipe (protective) is resistant to the influence of acid-base environment and ultraviolet radiation. It is reliable in various climatic conditions. Such broaching pipes have increased resistance to moisture, strength and elasticity.

There are also transparent corrugated pipes made, for example, of thermoplastic polyurethane, which exhibits resistance to hydrolysis and microorganisms. They are characterized by good tensile strength. Such a transparent pipe can be used in the chemical and polymer industries as a ventilation element or for supplying hot air.

Technical Parameters of Polymer Flexible Tubes with or without a Probe

PVC pipes often used for wiring inside a building. Operating temperatures range from -25 to +60 ° С, installation temperatures - from -5 to +60 ° С. The pipeline order can be with or without a metal probe. Light and heavy products are available with diameters of 5; 4; 3.2; 2.5; 2.0 and 1.6 cm.

HDPE flexible pipes are usually used for laying in concrete structures, and their planned operational period is 2.5 times longer than the durability of the power cable. Their manufactured diameters are the same as those of PVC pipes, but the temperature range is wider: from -40 to +90 ° С. Products are black or orange. A transparent coupling is used to connect the elements.

Superheavy pipes with or without a steel probe have diameters of 25 and 32 mm.

Polypropylene pipes are blue and have an operating temperature of -40 - +105 ° C. Installation temperature is -25 - +60 ° С. The minimum radius of their bend is three diameters.

Heavy and superheavy pipes can also be equipped with a probe, they are used for hidden communications

Strength indicators (compressive strength at 20 ° C) are given in the table.

table 2

| Series | Value |

| Easy | more than 120 N at 50 mm |

| Heavy | more than 320 N at 50 mm |

| Super heavy | more than 450 N per 50 mm |

The dielectric strength of a flexible polypropylene pipe is not less than 2 kV, the insulation resistance is not less than 100 MΩ.

Double-walled corrugated products (flexible) are available in orange with possible diameters: 5; 6.3; 7.5; 9.0; 11.0; 12.5; 14.0; 16.0; 20.0 cm. They are used in places with heavy traffic or high loads.

Thus, the use of corrugated pipes to protect cables during their installation protects them from mechanical stress and vibration. In addition, due to their characteristics, flexible pipes can be used as elements of various water supply, sewage and ventilation systems.