Casing - This is a design that is made of different materials and has a cylindrical shape. Installation of such a pipe is carried out directly into the drilled well. Similar products are used to protect the well from soil shedding. Today, the most popular are plastic products for casing wells.

Casing pipes are produced from various materials and are used for drilling water, oil, and gas wells.

Content

Casing Appointment

To date, two types of products are used:

- casing;

- core.

Upsetting structures are used to protect oil and gas wells, as well as when installing drinking wells in private homes. Core parts are used in well drilling and play a guiding role.

The main task of the casing is to protect the drilled well from falling asleep. This protective structure should be present in the mine from the beginning to the end of the operational period of the well. Such products must have high strength to withstand the pressure exerted on them by the soil. The right choice of material ensures a long service life of the structure (up to 50 years).

In addition, the casing must have good leakproofness. This is especially true of soils in which a large number of underground sources lie. The casing string must do its job well to prevent the entry of soil and groundwater into the well.

Casing parts are produced from a variety of materials: wood, cast iron, steel, asbestos cement, plastic. The most common are polymer products. This is due to the fact that their production is characterized by lower costs and simplicity. In addition, plastic pipes have several advantages over metal counterparts.

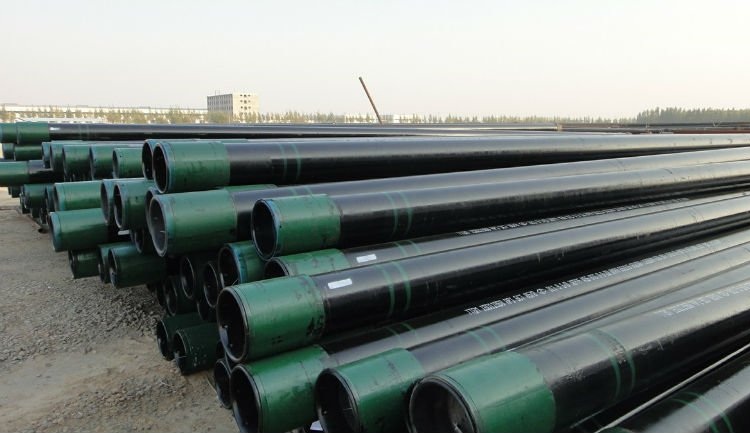

Use of casing in the oil and gas industry

To protect oil and gas wells use inventory, very durable casing. As a rule, only metal parts are used in the oil and gas sector. The main material in this case is steel. This is due to the fact that the plastic does not have sufficient strength indicators for working at such depths.

The sizes of these products vary from 9.5 to 13 m. The connection between them is made using special threads. Depending on the design features, the thread may have a conical section, a triangular section, etc. At high operating pressures (above 30 MPa), the thread is additionally equipped with rubber seals.

Important! Some types of pipes are used in the construction industry and can be used only once, because their installation is carried out with the entire structure being poured with concrete mortar. After completion of work, the dismantling of such a column is impossible even using special equipment.

The diameter sizes of such structures can be from 114 to 509 mm.In addition, the diameter has a direct effect on the wall thickness, which can have different indicators (from 6 to 16 mm).

Examples of the dependence of the casing wall thickness on the diameter are presented in table 1.

Table 1

| Diameter mm | Wall thickness mm |

| 426 | 10 – 12 |

| 324 | 8,5 – 14 |

| 194 | 7,5 – 13 |

| 125 | 6,2 – 10,5 |

The wall thickness indices of products for oil and gas wells are divided into 7 main groups, within which the following yield stresses are observed - 379–1067 mPa.

In addition, all these products are divided by the method of production into:

- ordinary (deviation of a linear indicator by 1 meter is up to 1 mm);

- with increased accuracy (deviation no higher than 0.5 mm).

The use of pipes for bored supports

Casing parts are widespread in the construction field. Here they are used for bored supports, which are performed by concreting the finished well. The diameter of this design can be from 300 to 1500 mm. The most popular are products with diameters from 300 to 600 mm.

For the installation of bored piles, a sectional casing is used. The connection of this design is by thread. The lower section of such a column has a special drilling element that passes through the soil when drilling. Installation of casing parts takes place thanks to mobile drilling machines (MBU).

In addition, there are types of bored piles made by hand. Using such a manual installation, it is possible to drill a well with a depth of 3 m and a diameter of up to 30 cm. In this case, the role of a casing pipe is played, as a rule, by a roll of roofing material, which encloses the walls of the well or ordinary plastic casing parts.

Application for water drinking wells

When arranging water wells use: plastic, steel and asbestos-cement parts. The most popular because of easy installation and low price are plastic pipes made of PVC and PE. For drilling such wells use special equipment. Well casing takes place after drilling. Docking of individual elements in such columns occurs due to threaded connections.

Important! The diameter of the well and the casing are selected based on the specific case, depending on what kind of source capacity is needed. The cross section of the column must be such that a pumping device can be placed in it. The lower sections of the structure must be mounted from perforated pipes.

Although metal and asbestos-cement parts are suitable for mounting wells on water, their use has certain drawbacks.

Types of Casing

There are three main types of casing: plastic, steel and asbestos cement. The choice of material depends on the characteristics of the soil, the depth of the well and other indicators. In order to determine the depth for the well, it is recommended to consult with specialists who are well versed in this matter.

The main requirements that the casing must comply with are:

- resistance to soil pressure;

- if the product is used for the installation of a drinking well, it must comply with sanitary standards;

- durability.

Consider the main varieties of products that are used for casing various kinds of wells.

Steel. The most durable parts that can perform their functions even at very high ground pressure.

Steel pipes have poor resistance to the harmful effects of corrosion. Over time, the water extracted from the source can become an unpleasant aftertaste of rust. This entails the cost of arranging filters.In addition, such products are a rather expensive option.

According to the type of production, there are two main types of steel pipes:

- seamless

- welded suture.

Seamless casing is characterized by excellent strength indicators, however, the cost of such parts is quite high. Welded sutures are cheap, but have poor strength.

In some cases, to improve the performance of steel products, they are made from improved materials or with a protective coating. First of all, this helps to protect them from rust. There are three main types of such pipes:

- Galvanized pipes. These products have good corrosion resistance, however, they emit hazardous zinc compounds. The use of such products for drinking water wells is not recommended.

- Stainless steel. It, like the previous type, is resistant to corrosion. The main disadvantage of such a pipe is its high price.

- Enameled pipes. Such products have many disadvantages: complex installation, thin walls, poor resistance to mechanical stress.

Galvanized pipe is not subject to corrosion, but it is not recommended to use it in drinking sources

Asbestos cement. The casing pipe made of asbestos cement is quite cheap, however, it is not recommended to be used for drinking purposes, because it releases carcinogens and other harmful impurities into the water. In addition, such products are very fragile.

But modern industry offers a variety of similar pipes from a modified material that is considered safe for humans. If you have clearly decided that you will use asbestos cement pipes for a well, then it is advisable to familiarize yourself with the sanitary certificate of products in order to be sure that your water will be suitable for use.

Plastic As mentioned above, this type of casing is the most popular and popular. Plastic parts are made of the following types of polymers: polyvinyl chloride, polyethylene and polypropylene. Plastic products have a number of positive characteristics:

- environmental friendliness;

- resistance to corrosion;

- cheapness;

- ease of installation;

- excellent tightness;

- the service life of such products can reach 50 years.

However, they also have their drawbacks:

- poor resistance to mechanical stress;

- limited depth of use (50-60 m).

The best characteristics that determine their choice are PE and PVC pipes. The most budget option is polyethylene products. The sizes of such products are distinguished by their diversity.

Casing pipes are also made of polymers - most often polyvinyl chloride and polyethylene are used for such products.

If we talk about PVC and PVC-U pipes, then, by their characteristics, pipes from unplasticized polyvinyl chloride are the leaders. They have high strength - they are allowed to be used in wells up to 300 m. The sizes of casing PVC-U and PVC pipes are presented in table 2.

table 2

| Diameter mm | Wall thickness mm |

| 165 | 12 |

| 140 | 10 |

| 125 | 7,6 |

| 110 | 6,3 |

| 90 | 4,3 |

Note! Most often, when installing wells, pipes with sizes 90 and 125 mm are used. This is due to the fact that this size fits the largest number of modern pumping devices.

Minuses PVC pipe casing:

- low strength;

- poor resistance to low temperatures;

- the complexity of processing the material;

- in case of fire emit harmful compounds.

Casing Connection Options

The casing consists of individual elements that are interconnected in a variety of ways. Consider the options for joining pipes in casing.

Threaded connection. Used in cases where it is necessary to assemble products that are equipped with upset ends.The planted end heats up and distribution is carried out on it (approximately 10 mm in diameter to a length of 150-200 mm). As a result, an internal-type thread is applied to this end, and an external thread with corresponding characteristics is cut into the opposite end. To connect the elements are simply screwed together.

Coupling connection. An external type of thread is applied to the ends of the products. Couplings that combine pipes into a single design have the corresponding internal thread. Transportation and delivery of such parts is carried out with a coupling screwed onto one end. The second end, as a rule, is closed with a special plastic plug.

Welded joint. It is used extremely rarely. A very important point in such a connection is its rectilinear deviation, which should not exceed 0.7 mm at the junction.

Welded joints are divided into the following types:

- bell type;

- butt

- two-socketed docking;

- coupling connection

- nipple - bell-shaped;

- two-bell with a central ring.

One of the most reliable and durable is the double-socket casing jointing. Socket and socket have the same strength indicators, which are slightly lower than that of a two-socket. Butt joint strength often reaches that of the pipe itself. The segments are welded over the wellhead using special welding machines.

There are such types of welding:

- in a protective environment;

- in a defenseless environment;

- contact welding.

Helpful information! In addition, you need to pay attention to the separation of pipes into pressure and pressureless. For casing use pressure products. Such parts have good resistance to high pressure.

It is worth paying attention to such features: the initial section is equipped with a special filtering device that purifies water from sand and clay. Such a device is made, as a rule, of nets or stainless wires. The bottom open end has a special gravel filter. In this device, primary fluid filtration takes place.

The head of the well must be mounted taking into account tightness. If this rule is observed, then pressure is generated during pumping out of the water, which contributes to the supply of water to the intake element.