Stainless steel is a chromium-containing alloy of steel. Standard technology provides that the amount of chromium in the final product is at least 12 percent. It is this component that provides stainless steel with increased resistance to corrosion. Therefore, the pipe made of stainless steel GOST 9941-81 can be used in industries with high demands on the durability of the structure created on its basis.

Content

GOST 9941-81. Key points

This standard describes seamless cold and heat-deformed tube products. For their manufacture, an alloy is used, the chemical composition of which is determined by GOST on 5632 72 stainless steel. The outer diameter of the pipes ranges from 5 ≤ Dvn ≤ 273 mm, and their wall thickness 0.2 ≤ SArt.≤ 22 mm.

Products are produced unmeasured, standard measured (7 m) and multiple measured length. It should be noted the loyalty of standard 9941-81 in relation to the requests of potential consumers of corrosion-resistant pipes. Their production is allowed with a length of 0.5 ≤ L ≤ 16 m. True, the manufacture of non-standard stainless steel pipes GOST 9941-81 requires agreement with the customer.

One batch of finished products, including products of unlimited length, can be understaffed with pipes of length:

- 0.50 ≤ L ≤ 0.75 m with wall thicknesses up to 0.50 mm;

- 0.75 ≤ L ≤1.0 m with a wall from 0.50 to 1.0 mm;

- 0, 75 ≤ L ≤1.5 m, if the wall thickness of the stainless steel pipes GOST 9941-81 exceeds 1 mm.

However, the number of products of the indicated sizes should not be more than six percent in one batch.

All products of stainless steel pipe are divided into pipes of high, ordinary and high accuracy. Deviations of wall thickness (Sst.) From the standard value of GOST allows within the following limits:

- -10 ≤ Sst ≤ + 12.5% (high-precision pipes);

- 0.05 ... 0.15 mm (conventional accuracy);

- -10 ≤ Sst ≤ +12.5% and 0.03 ... 0.10 millimeters (high accuracy).

As for the deviations of the outer diameter, in GOST for stainless pipes 9941-81 there are the following numbers:

- high-precision with a diameter of 5.0 ... 10.0 mm - a deviation of 0.15 mm;

- ordinary with a diameter of 10.0 ... .30.0 mm - up to 0.80 mm;

- high accuracy - from 0.4 to a maximum of 1.2%.

For conventional products of precision steel 06KHN28MDT with a cross section of less than 30 mm, a deviation of 0.45 mm is allowed. If the diameter exceeds 30 mm, then 1.2%.

Requirements for stainless steel pipe GOST 9941-81

The basic requirements for the quality of such products can be formulated as follows:

- the cutting angle of the ends of the finished products should be equal to 90 degrees. The burrs formed during cutting must be removed.

- the curvature of any running meter of a stainless steel pipe GOST 9941-81 can have the following indicators: 1 mm (diameter more than 5 mm, and wall thickness more than 0.50 mm), 2 mm (structures with a cross section of more than 15 mm and wall thickness up to 0.50 mm )

When checking the quality of the pipes produced, the cut is evaluated - it should not have any burrs or other defects

Note! This process is accompanied by the formation of chamfers. Sometimes in the supply contract there is a separate point of their mandatory presence at the ends of structures with wall thicknesses exceeding 5 mm.This allows the customer to more effectively and efficiently perform welded pipe joints.

There is no special regulation for products with a diameter of up to 1.5 cm and with a wall thickness of less than 0.5 cm in the considered GOST for stainless steel pipes. The main thing is that they do not have sharp bends. As for ovality, it should not deduce the pipe diameter beyond the maximum permissible values.

The following steel grades are used for the production of stainless steel pipes GOST 9941-81: 12X13, 15X25T, 12X18H10, 08X22H6T, 08X13, 12X17, 04X18H10, 10X17H13M2T, 10X23H18, 08X18H10T, 08X17H15M3T, 12X18H12T, 17X18H9 and some others. The index of temporary resistance of such alloys ranges from 38 ... 588 kgf / m2, relative elongation 17 ≤ ΔL ≤ 45%, density 7.7 ≤ P ≤ 7.960 g / cm2. The inclusion of rare-earth metals in these grades of steel is allowed. However, their percentage should meet the requirements of the above GOST stainless steel 5632 72. The presence of sulfur is given special attention. Its content in the metal should not be more than 0.02%. The final product is subjected to heat treatment, but only in consultation with the consumer.

Returning to the requirements for the quality of pipes made of stainless steel GOST 9940-81, it is necessary to add that on their inner and outer surface the presence of flaws, sunsets, cracks and captivity is not allowed. To get rid of them, the following methods are used:

- boring;

- local cleaning of problem areas;

- turning;

- local or continuous grinding.

In this case, the removal of detected defects should not cause the section and walls of the stainless steel pipe GOST 9941-81 to go beyond the allowed deviation indicators.

A specific embodiment of the manufacture of products of this type, as well as the use of certain alloys, sometimes cause a gray tint to appear on their matte surface. This is not considered a defect, although according to GOST the surface of the stainless steel pipe should be light. And this is not the only exception to this requirement. One more thing sounds like this: if, after heat treatment, the etching procedure in a protective medium or in a vacuum is not provided, the discoloration colors present on the pipe are not considered defects.

Steel Product Manufacturing

Existing manufacturing methods allow the production of stainless steel pipes of two main types:

- seamless

- with a weld seam.

GOST 9941-81 was described above, the effect of which extends to seamless heat- and cold-deformed products. The production of hot-deformed products is regulated by standard 9940-81. Both state standards stipulate that the manufacture seamless stainless pipes carried out using casting and crimping technology. A product of a certain diameter is obtained as a result of the workpiece being put on a special rod.

Important! However, production according to the requirements of GOST 9941-81 differs in that it processes cold, rather than incandescent, billets. But in any case, being worn on the frame, it is exposed to a number of rollers that form a given diameter and wall thickness along the entire length of the pipe.

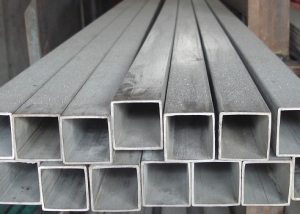

At the final stage, a cold-deformed product is heated and allowed to cool naturally. This procedure is designed to relieve stress in the metal pipes seamless stainless. GOST 9941-81 stipulates the need for its implementation especially. In addition to round, modern metallurgy produces products with a rectangular, square, and oval cross-section, forming a separate category of profile pipes from stainless steel GOST 30245-2003. A square section is convenient when the load is distributed evenly. The use of rectangular stainless steel pipes GOST 8639 82 is justified under uneven loads.

The main advantages of the profile pipe products of metal rolling include:

- the presence of stiffening ribs in rectangular and square products gives the structure greater strength;

- rectangular and square sections have logistical advantages. Products of this shape are easy to transport and store.

- hollow rectangular and square pipes are suitable for placement of any communications, starting from cable power networks and ending with water lines;

- Due to the shape, the installation of a rectangular and square stainless steel pipe GOST 30245-2003 does not cause any difficulties:

The use of rectangular and square pipes made of stainless steel makes it possible to reduce the cost of the structures created by reducing the metal consumption without compromising their high strength characteristics.