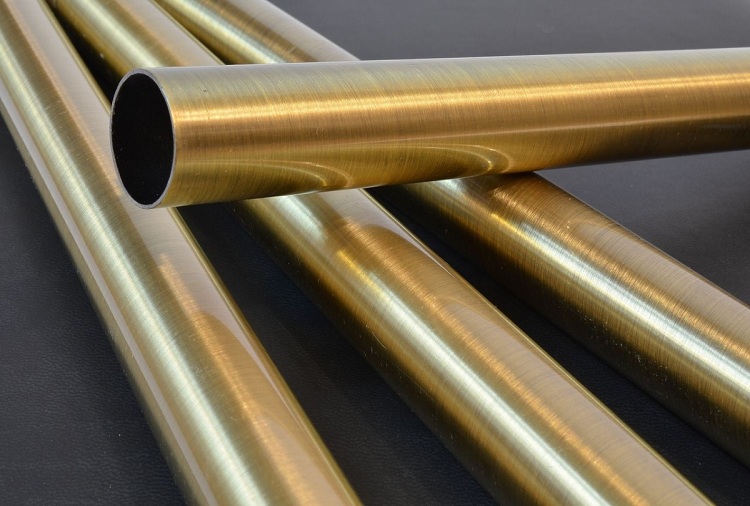

Brass pipes are produced using a special alloy, which includes copper, as the basis of the alloy, and zinc (an alloying element). Sometimes tin or other metals are added to the alloy to improve its quality characteristics. The more the composition contains zinc, the more yellow is its color. The brass pipe has become widespread throughout the world in various fields of industry from heating systems in residential buildings, to energy and shipbuilding.

Brass pipes have high strength characteristics and can be used for a variety of purposes in industry and everyday life.

Content

Features of brass products

The manufacture of brass products is carried out by the method of cold deformation and pressing of the material. Zinc in the alloy plays a very important role, increasing strength indicators. The more zinc is contained in the alloy, the higher the figure, which determines the characteristics and type of product. Another important indicator is plasticity. The optimum plasticity parameters are possessed by the L68 brand.

When buying a brass part, it is worth focusing on the parameters that are indicated by the product standard. According to this document, cold-rolled and drawn pipe products are represented by three types: hard, semi-solid and soft (this applies to thick-walled and thin-walled products). Semi-solid brass parts are subject to additional processing, which eliminates the tensile stresses of the internal walls.

Important! You can study in more detail all the requirements and characteristics of brass pipes in the GOST document, which is freely available on the Internet.

The rules that are set out in GOST also have requirements for the surface of parts. Brass products must be manufactured in accordance with all technical standards and must not have dents, cracks, sinks or burrs on their surface. The presence of small defects is allowed, which can be easily eliminated by cleaning the surface of the product.

The characteristics of some types of pipes are presented in the table.

Table 1

| Alloy type | Outer diameter mm | Thickness mm |

| LS59-1, L63 | 30-195 | 4-42,5 |

| LK75-0.5 | 56-100 | 1,0-10,0 |

| 21-55 | 1,0-7,0 | |

| 10-20 | 0,8-3,0 | |

| L63 and L68 | 56-100 | 1,0-10,0 |

| 21-55 | 1,0-7,0 | |

| 10-20 | 0,8-3,0 |

Such an alloy makes not only round pipes, but also other shapes: rectangular, multifaceted or square brass pipes. Profile products are widely used in construction, production of furniture fittings. In addition, such details can serve as elements of the decor of the room.

Positive qualities of brass pipes

Products made of brass, as a rule, have excellent characteristics and quality indicators. Therefore, the cost of a brass product often exceeds its counterparts from ferrous metals.

The main advantages of parts made of this alloy include:

- high rates of strength and endurance;

- resistance to mechanical loads;

- excellent anti-corrosion performance. Pipes made of brass practically do not undergo destructive corrosion;

- resistance to sharp temperature drops;

- antifriction properties (have a low coefficient of friction);

- ease of installation, handling and replacement;

- a sufficiently long period of service (up to 50 years).

Types of Brass Pipes

For the manufacture of brass products, as a rule, alloys are used that have a diverse composition and different ratios of alloying elements. This is done in order to produce pipes with different technical characteristics for different needs. The addition of dopants occurs at different stages of production. The class of finished products can be foundry or plastic (deformable). Subclasses may also be made for further processing and production of new types of product.

As mentioned above, pipes are divided into thick-walled and thin-walled. Consider these two types in more detail.

Thick-walled pipes. Such a product, due to its quality characteristics, can be used in various industries for laying pipelines in large enterprises. These pipes are made without connecting seams and are used in the transportation of gases and liquids with high pressure. They are not used for domestic pipelines, because it does not make sense, because they are designed for heavy loads, which simply do not exist in everyday life.

Pipe brass cold-rolled thin-walled. This type of pipe has found application in the housing sector. They have more modest characteristics than thick-walled ones. As a rule, they are used for installation of pipelines in residential premises, as well as for boiler systems. Such parts are made using cold rolling and pressing. They are widely used due to their excellent anti-corrosion and strength characteristics.

Note! Brass has higher strength values than copper without impurities of other metals. In addition, almost all types of brass alloys are quite simply processed mechanically and using pressure at any temperature. They are also excellently combined by soft and hard soldering.

There is a pipe that has unique qualitative characteristics - profile. Profile brass tubes have various types of section. It can be square, rectangular or oval. These pipes have a high density and excellent elasticity indicators, which makes them indispensable in various fields (especially in construction).

Brass pipelines

Brass pipes can be used as part of water supply systems in both residential and industrial. However, this is a rather rare occurrence. Now, when it is possible to buy cheap plastic or metal-plastic pipes, it simply does not make sense to install brass in your home. But they are also used for this purpose, albeit not as often as their competitors. They are recommended to be used as an alternative to bulky, heavy pipes made of other metals.

Unlike pipes, brass fittings are very widespread. Their popularity is due to the fact that they have light weight, a huge number of varieties for any purpose and type of pipe and, in addition, are relatively cheap. The ease of installation of these connecting elements also plays an important role (they are installed without special tools).

Brass pipes are distinguished by excellent quality indicators and durability. These products have anti-corrosion properties that are so important, especially when installing metal pipelines. When choosing these parts, it is necessary to study their types and characteristics, because these products have a number of features and "contraindications" to use. But you can always consult with specialists who will help you choose the right product.