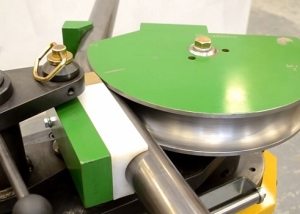

A mandrel pipe bender is a device that includes a workpiece - a mandrel, it is located at the bend point and prevents unnecessary deformation of the pipe, section and crease.

The differences between a machine tool with a mandrel and other types of equipment of the same orientation are that it has a specific design that allows you to perform pipe bending work at a high level, with a small percentage of rejects. Such equipment allows you to get a smooth bend and is in great demand at manufacturing enterprises.

Dorn pipe bender allows you to get accurate bends and completely eliminate pipe deformation during surgery

Content

Features bending a pipe bender with a mandrel

There are many structures made of pipes, they go to different structures: from installing horizontal bars on school grounds and to laying water and gas pipelines. Pipes are also actively used in the automotive industry, where many parts are made from them.

As you know, the fewer connecting elements and joints the structure has, the more reliable it is. Seams can leak, resulting in leakage of the substance transported through the pipe, which in itself carries a danger to human life. To minimize the possibility of an accident, pipe benders are used that bend a long solid pipe to the required angle. The main advantage of such a machine is that the bend is almost perfect. An endless pipe bender cannot bend such a high quality.

Pipe benders with a protector are recommended for use with thin-walled pipes. Massive pipes with thick walls are not processed with it. Such a machine is in great demand, because with high efficiency a minimum of human forces is expended. The structure and material of the bending machine depends on the scope in which it is used, and the parts processed on it. Dorn can be either steel or brass or even plastic.

The dorn, placed inside the pipe, takes the form of the desired bend and does not allow creases to form on the workpiece

Types of mandrel pipe benders

The pipe bender can be automatic or semi-automatic. Semi-automatic pipe benders are cheaper. But part of the work is done manually, and this often requires a lot of effort.

Management of an automated workflow is performed by a CNC machine equipped with a computer. Previously, a bend scheme with all parameters and numbers is entered into it. One person is enough to service the whole process.

A pipe bender can give the pipe a variety of bending angles. But the radius should not exceed two radii of the pipe itself. If bending is excluded and the desired shape of the structure is made using connecting elements (fittings), then the strength and reliability of the structure will be much lower than that of its monolithic analogue.

Types of pipe benders:

- crossbow - a frame in the shape of the letter "T". It includes a pipe holder and a movable lever located perpendicularly. The manual device is mainly used in the installation of heating and plumbing systems. Able to bend pipes, forming an angle up to 180 °;

- hydraulic - is manual and stationary.Manual ones are designed for bending pipes with a small diameter, while stationary ones are used in factories and can bend workpieces of dimensions up to 100 mm across. Such a bender performs an angle up to 90 °;

- electric - this type is used in a widespread sense. Performs folds of almost any complexity. Its work is completely controlled by automation, so the accuracy of bending the part is perfect.

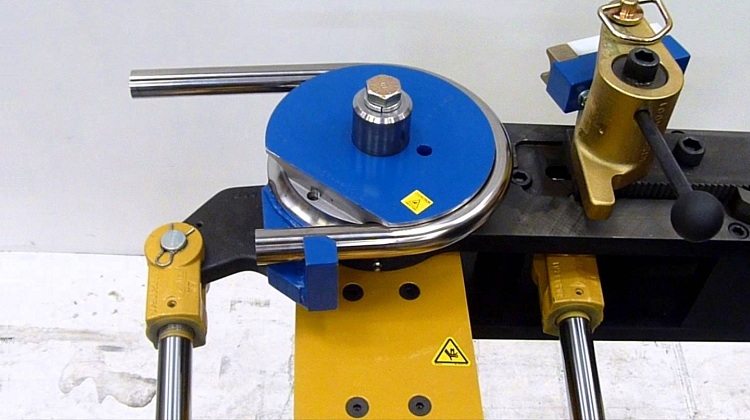

Dorn pipe benders use different workflow schemes. In hydraulic as well as crossbow systems, the part is precisely machined. Widespread circuits in which there are roller parts. In such cases, bending occurs by gradually winding the part onto the rollers.

Due to the specificity of its design, this device is a stationary equipment. For the work of a pipe bender of a serial type, the mandatory presence of power is required.

Important! If you have difficulty bending thin-walled parts, it is best to get a mandrel professional pipe bender.

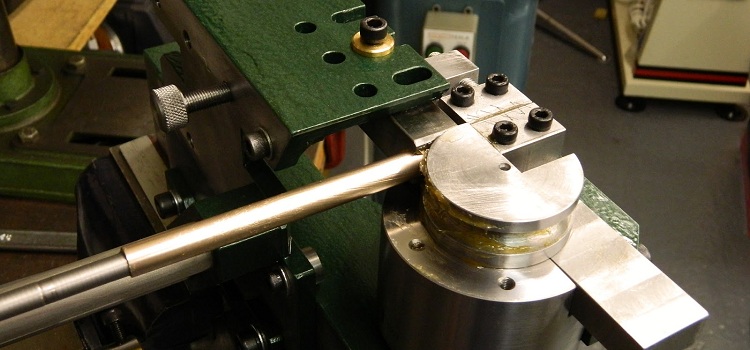

Bender with a mandrel: structural components

The mandrel type apparatus consists of the following parts:

- frame with guides - the main part that serves as a working surface;

- cast-iron head - a part that creates a bending moment;

- hydraulic booster - acts as an amplifier for the bending head;

- cartridge - needed to secure the workpiece on the work surface;

- bending roller - sets the radius along which the bending will take place;

- clamping pads - perform fixing work. Mounted in the bend area;

- mandrel mandrels and traction - clamping pads are mounted on them;

- tensioning bracket - the part on which the mandrels and rods are placed.

The most complex design is also for automatic pipe benders, but they give the most accurate bending with minimal time and effort.

The frame of the device is made of durable steel, and the cast-iron head creates a high rate of bending moment. At the same time, its location is mirrored on the computer and can be watched. Pipe bending machine can combine the finger and upper types of clamp. The first type differs from the second in that the bending lever is not subjected to stress. The upper type of clamp forms a gap between itself and the surface of the part. Due to this, the pipe can move in a linear direction.

The machine is also equipped with a hydraulic component - a booster. The clamp has a cartridge and mechanical stops and is located on linear guides. Mechanical stops define the plane of the pipe.

The main advantages of operating a mandrel bender

An endless pipe bender bends pipes under pressure, which is created using various types of actuators - from hydraulic to manual. The pipe that is being processed is subjected to pressure and the wall located on the inner bend radius begins to deform, forming an angle. In the process of bending, a corrugation is formed on its surface - a wavy section. The wall on the outside, on the contrary, is stretched, which entails its weakening. As a result of such a bend, the pipe deforms and loses its strength after the end of work.

The mandrel is an element due to which it is possible to minimize surface changes of the part. With the mandrel, the walls of the product are deformed smoothly and as evenly as possible.

Important! Thick pipes can also be processed by a bottomless pipe bender, but thin pipes (especially from ductile metals), without exception, must be bent on pipe benders of a dorn type. If this rule is ignored, the thin-walled pipe is strongly deformed and will be unsuitable for operation.

Thick wall pipes can be machined on a bottomless pipe bender without risking damage to the workpiece.

Mandrel grease

Lubrication of the mandrel is a very important process, it contributes to uniform bending of the pipe. Lubrication is necessary in order to reduce the friction force when bending a pipe under pressure. Dorn can be lubricated with a brush, but this is not the best option, since in this case it is impossible to count on the uniform distribution of the product on the surface of the mandrel. Spray is also an ineffective option. It is best to apply the lubricant impulsively using a hand pump. When doing this, you need to be very careful that the oil on the surface is distributed evenly.

Pipe benders with a stabilizing part (mandrel) are much more professional equipment than manual or home-made. Such a machine performs pipe bending work faster and better at almost any angle, which makes it possible to produce strong and durable structures without any connecting elements. But do not forget that bending metal pipes with a mandrel is a process that requires appropriate training.