Ventilation in a private and apartment building is one of the most important communication systems. The efficiency of its functioning and the timely elimination of unpleasant odors depend on the correct installation of plastic ducts for the kitchen hood. Air exchange provides comfortable working conditions in the kitchen and stay in the house. The most common for the arrangement of ventilation are polyvinyl chloride (PVC) pipes.

Content

Types of pipes for ventilation

Smooth polymer pipes (PVC, polypropylene, polyurethane) galvanized and corrugated from steel or aluminum are used for air ducts. The latter have a ribbed surface, therefore, when folded, they create a lot of noise and retain fat and dirt, which requires regular cleaning. Plastic ventilation pipes in a private house can be led out through the roof or wall. On sale there are insulated options for ducts.

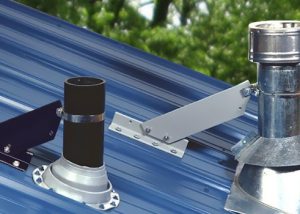

In a private house, an exhaust pipe can be used to exhaust the combustion products of a gas boiler through the roof. In winter, air temperature significantly decreases and humidity increases, which leads to the appearance of condensate. To prevent this, the outlet of the ventilation plastic pipe for the hood to the roof should be insulated. Condensation may damage the connections. As a result, moisture will drain through the pipes and destroy the building structure. PVC itself and corrugated pipes are not affected by it.

An insulated plastic ventilation pipe is usually located in the attic of a house. You can protect the duct leading to the roof from the appearance of condensation with your own hands.

The main elements of the ventilation system

The ventilation system consists of the following elements:

- Ventilation duct. Selection is carried out depending on the required section and size. It is easier to use a profile plastic pipe in the kitchen for hoods, since it is quite simple to mount. Typical dimensions of rectangular ducts are 60x120 mm and 60x204 mm.

- Connectors They are equivalent and transitional. The latter are used to connect plastic ventilation pipes of different sizes, while the transition is smooth.

- Twists and turns. They are used to change the direction of the plastic ventilation pipe in a horizontal or vertical plane.

- Tees. They have all outputs of the same cross section and a standard branch angle of 90 °.

- Fasteners. Used for quick installation of plastic pipes for ventilation.

- Non-return valve. Allows you to set the desired direction of air flow. Most often it is used in forced ventilation with the fan turned off to prevent air from entering the street.

There are also transitions from ventilation plastic pipes of rectangular cross-section to round and other specialized products that allow you to mount your own air exchange system in the house.

All additional elements are selected taking into account the dimensions of the main pipe.

Important! It is not recommended to install the stove and hood on the opposite side from the outlet of the ventilation channel. This will reduce the efficiency of the system.

Properties of smooth plastic exhaust pipes

Plastic pipes for ventilation are resistant to corrosion. The smooth inner surface creates the best conditions for silent and unhindered air movement. In addition, plastic ventilation pipes do not need to be cleaned and have a long service life, can be discharged through the roof or wall. Such ducts are round and rectangular.

Often used to extract ventilation PVC pipes. Their advantages are:

- light weight;

- tightness, lack of cracks in which dirt can clog;

- ease of transportation and installation do-it-yourself;

- durability and strength.

However, the PVC ventilation pipe has a low melting point, which does not allow it to be used as an air duct with a temperature above 50 ° C.

A round plastic ventilation pipe has less resistance than a rectangular duct. For connection, L-shaped adapters are used. It is possible to improve the quality of joining of plastic rectangular pipes for ventilation with sealant.

Features of corrugated pipes

Corrugated exhaust ducts have an important advantage - they are very easy to install. For self-assembly, round clamps are used, which are pulled together by bolts. One end is attached to the ventilation duct overlooking the roof, the other to the kitchen hood.

The advantages of using such pipes are:

- the corrugation can be installed with a larger cross section than the diameter of the hood. To this end, the duct is pressed tightly to the adapter with a clamp.

- the possibility of stretching the pipe over long distances;

- compactness (when folded, the three-meter section takes 1 m);

- air resistance inside the pipe;

- operating temperature from -30 ° C to +120.

The design features of the hood are such that the output has a square shape. Therefore, when assembling ventilation from plastic pipes with your own hands, you should buy adapters for round sections.

Unlike flat PVC ventilation pipes, corrugated pipes, thanks to their flexibility, can be effectively used in a complex kitchen.

Important! To reduce the noise level, the corrugated duct must be stretched as far as possible.

Choosing the right duct design

The diameter of the PVC duct for the hood is selected smaller than the hole of the hood itself. Otherwise, performance will be reduced, the load on the motor and the noise level of the plastic pipe for ventilation will increase. The ventilation pipe should not have many bends and be very long. Each rotation of the plastic duct for drawing at a right angle reduces the efficiency of the system by 10%. Bending in excess of 90 ° can lead to a violation of the correct outflow of air from the cooker hood in the house.

The installation of a non-return valve prevents the back draft in PVC pipes for ventilation. Its rotary axis must be placed in a vertical position.

The organization of air exhaust in the house through the roof or wall using the ventilation duct should not interfere with natural ventilation. It is possible to use a special combined grille with a pipe on top and openings for natural ventilation from below. A PVC pipe for hood is connected to the pipe.

The optimum duct length is 3 m. With the lengthening of the PVC pipe per meter, the efficiency of the kitchen hood is reduced by 5-10%.

Rules for installing the ventilation system

When assembling ventilation from plastic pipes in a private house with your own hands, you need to pay attention to such points:

- Reliability of fastenings. It affects the performance of the hood and the entire ventilation system, provides long-term tightness. It is considered standard to place fasteners on long lines every 2 meters, on short lines after 1 meter. In a private house, it is better to fix both rectangular and round ducts in each section of the connection, and tees - on 2 clamps.

- Tightness of the connection of plastic pipes for ventilation. If the assembly was carried out incorrectly, unclean air can enter the room through leaking joints of the PVC ducts. Unlike sewers, ventilation from plastic pipes does not involve the use of rubber seals. It is necessary that the air moves towards the bell.

- Correct organization of the outlet (air discharge) and inlet (air intake) of the system. A fan is mounted at the inlet to the ventilating plastic pipe for the hood, and a grille is installed at the outlet. In the case of the supply duct, on the contrary, only the fan is located directly in the pipe.

Important! The ventilation hole must not be completely covered so as not to interfere with the air exchange in the house.

The hood in the kitchen of an apartment building is mounted much easier. In this case, the task of the master is to choose the right diameter of the connecting elements and pipes and securely fasten them to the wall.

Before starting the installation of pipes, you need to make measurements and mark the places of fastenings

Masking methods for exhaust ducts

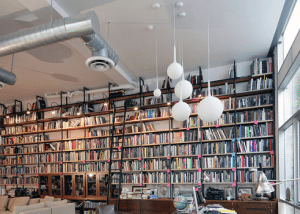

In addition to the direct purpose in the kitchen, air ducts should organically fit into the interior. It is most convenient to mask rectangular plastic ventilation pipes for hoods. They can be placed under the ceiling above the wall cabinets. If necessary, paint to match the walls. For the hood, ventilation plastic pipe, you can provide for the location directly in the kitchen furniture.

At the stage of planning the installation of a suspended or suspended ceiling in the kitchen, you can provide a special design for a plastic duct for hoods. If the ventilation system is already installed, then it can be hidden in a special decorative box. It comes in various shapes, colors and provides quick access to communications if necessary. This method is good for hiding the corrugated plastic pipe for ventilation, which looks the most unpresentable and requires masking.

Some manufacturers offer to buy all the elements of the system at the same time. Thus, the hood, plastic pipes for it are purchased in one color, which allows not to carry out additional masking.

It is better to use pipes for drawing, nevertheless plastic, in which air is removed without creating vibrations and loads on the supporting structures.