Today for repairs involving water system replacementheating or sewage systems are used predominantly plastic pipes. They quickly broke into the building materials market at the end of the 20th century and took a leading position. Convenience in work is their main advantage. Nevertheless, without knowledge of a number of subtleties, how to correctly solder plastic pipes, qualitatively to connect them into a single system is impossible.

Content

Work Tools

To solder plastic pipes you will need:

- a welding device designed to work with this material;

- special scissors;

- building level;

- marker;

- roulette.

Practically any household chores the master has at his disposal all these tools, except the first. If the procedure for soldering plastic pipes is supposed to be performed only once, it would be much more advisable to rent a welding device or borrow it rather than buy it.

Before proceeding with the do-it-yourself soldering, you should briefly familiarize yourself with such a device. An important functional component is the sole with heating elements. The presence of special holes on it, which allow fixing special nozzles for welding, provides ease of use. The temperature is adjusted using a temperature controller located on the body of the welding device.

How to solder plastic water pipes

Before starting work on connecting the water supply elements with your own hands, install the device in the desired position and fix the nozzles on it, having previously selected them in size. After that, using the thermostat, set the desired temperature. Soldering plastic pipes made of polypropylene carried out at + 260 +С. The optimum temperature for soldering plastic pipes made of polyethylene is + 220 ° C. Remember these numbers - they will come in handy for the correct execution of work.

Do the soldering of plastic pipes with your own hands in the following sequence:

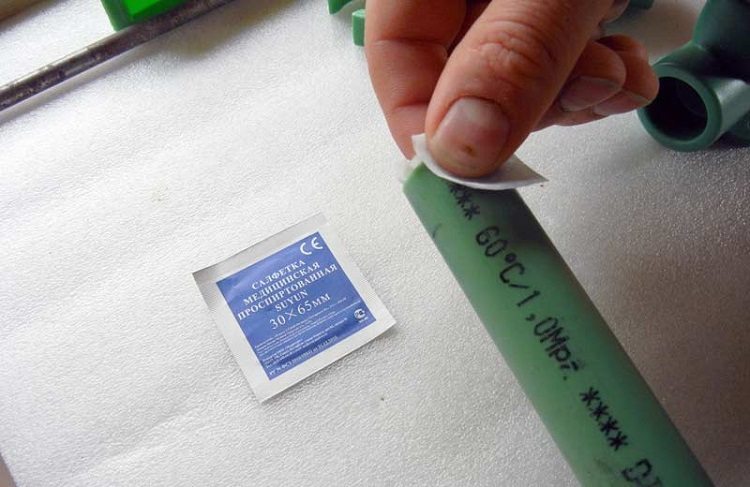

- cut the pipe to the required length. Using an alcohol solution, clean the joints and grease and dirt;

- install the pipe as well as the return bell in the nozzle. Warm up for a certain period of time;

- upon its expiration, insert the pipe into the socket, thus connecting the heated elements of the future water supply.

A sign of proper soldering of plastic water pipes is the formation around the entire circumference of a continuous influx in the form of a roller.

Important! This operation should take from 4 to 12 seconds, depending on the diameter of the elements to be joined. And remember that only strict adherence to the technology of soldering plastic pipes ensures their compliance with the required performance and durability of the joints.

Recommendations for a good pipe connection

The answer to the question of how to solder pipes made of plastic will be incomplete without mentioning the advice of professionals. They can be briefly voiced as follows:

- to correctly solder the plastic elements of the water supply or sewer piping, before performing the first welding, stand soldering iron in a state heated to the required temperature for at least 5 minutes;

- Soldering plastic pipes, allow them to cool, not allowing them to move and scroll, otherwise the seam will turn out to be of poor quality. In this case, you will have to cut the joint, discard the damaged fitting and perform the entire procedure again;

- when soldering plastic pipes reinforced with aluminum, remove the two upper layers from them, and only after that make the connection using the above technology;

- plastic pipes can be soldered at an ambient temperature of at least 0 ° C.

Precautions when using the welding machine also do not interfere. Some "craftsmen", having learned how to make plastic pipes for water pipes with their own hands, often do not attach due importance to this aspect. But in vain! With a superficial understanding of how to solder pipes from plastic, this approach may ultimately affect the quality of the connection. In addition, hot parts can cause serious injury.

How to solder sewer pipes from plastic

A welding machine is not the only thing that solders plastic pipes. You can solder the elements of the sewage disposal system with your own hands, using the simpler method. It is called so: cold welding. He performs the connection of pipes made of plastic without soldering. For this, a special adhesive composition is used, the application of which on the polymer surface leads to its dissolution and the mutual penetration of particles of the mating components of the pipeline. If you want to solder sewer pipes with the lowest material and physical costs, cold welding is the best option.

Soldering plastic pipes in this way is necessary in the following sequence:

- clean the joints with sandpaper;

- apply glue to the entire segment of the sewer pipe that will be inserted into the socket. In addition, cover with adhesive composition the inner surface of the socket on two-thirds of its length;

- Align the pipes with the glue applied all the way, turn them 90 degrees and press for a maximum of 60 seconds.

Having found out how the plastic pipe is sealed, do not rush to immediately begin work. The intricacies of working with the adhesive should be studied: after mixing, it should be used in no more than 5 minutes. Therefore, before proceeding with gluing, determine the amount of work.

Helpful advice! After assembling the sewer system, wait at least an hour before filling it with water for a test run.

If the test was successful and no leaks were found, feel free to hand over the pipeline to operation.