As you know, various modern substances are transported through modern engineering, industrial, urban and other utilities that can harm human health and the environment. In view of this, even in the era of the USSR, painting of pipelines was used to alert service personnel about the contents of the highway with which they would have to work. Color marking is now regulated by a special document GOST 14202 69.

Piping painting in many cases is a necessary measure - the purpose of the pipeline is determined by the color of the pipes

Content

Color purpose

It is worth noting that the requirement for painting pipes is not from the recommendation category. Moreover, failure to comply or non-compliance with the requirements of SNiP in the appropriate manner shall be prosecuted by law.

This is not happening because someone wanted to transform the world around them by painting them with fresh new colors. Indeed, like any other technological objects, pipelines must be maintained, repaired, and besides, accidents can occur with them. And the Ministry of Emergency Situations, rescue services and other organizations of this profile should have information on which substances they will have to contact, on the basis of which they can develop a set of measures to eliminate or localize the danger.

It will be useful to recall that not only tap water, heating substrates and sewage drains are transported through pipelines. Modern production, and in particular the chemical industry, has long used such substances in its technological processes as:

- explosive and combustible gases and liquids of various origins;

- toxic gases and liquids;

- saturated steam;

- superheated steam;

- substances with high blood pressure;

- non-combustible liquids and gases;

- alkalis of various composition;

- acids, including concentrated and smoking;

- hazardous organic compounds;

- air vacuum;

- other particularly important or hazardous substances.

By the color of the pipeline you can understand how dangerous its working environment is and how to work with it in case of an accident

On a note! In addition to the immediate danger posed by the chemical composition of the substance being transported, pressure and volume, as well as temperature, both low and high, play an important role.

The color of industrial pipes is relevant because ignorance of what substance will have to be handled in an accident at a large production facility can lead to catastrophic consequences not only on a regional, but also on a national scale.

How to paint pipes in accordance with GOST14202-69

It must be said right away that this document puts forward a special requirement for the identification of fire pipelines. This is due to the fact that to extinguish fires, substances in various states of aggregation can be used. That is, not only water, but also steam, foam, as well as other substances. The above requirement is formulated as follows: for any contents, fire lines are painted red.

In general, the identification color of utilities, depending on the type of substance transported, is indicated in the table below.

Table 1

|

Identification Color |

Transported substance |

| Green | Water |

| Red | Steam |

| Blue | Air |

| Yellow | Combustible and non-combustible gases |

| Orange | Acids |

| Violet | Alkalis |

| Brown | Flammable and non-combustible liquids |

| Gray | Other substances |

Often, the identification color is combined with the protective one - a color is applied to the pipeline that characterizes the transported medium. However, this approach is sometimes impossible to implement. For example, the identification painting of heating pipes laid in the basement of a private house does not make sense, since they are covered with a layer of thermal insulation.

Such cases also include:

- when specific conditions require that the color of the protective coating be different from that required by GOST14202-69;

- factory protective coating has already been applied to the pipeline;

- the pipeline is made of non-ferrous metal. Then coloring it is not required.

In these cases, GOST14202-69 allows for identifying coloring by sections of the pipeline, and not along its entire length. For branches of utilities with a diameter of up to 300 millimeters (including thermal insulation), the width of the colored sections should be equal to or greater than 4 diameters, and for pipelines with a cross section greater than 300 millimeters - not less than twice the value of this indicator. The strips are applied at intervals of not more than 60 m on the main external pipelines, and in rooms and outdoor installations - not more than 10 m.

Marking Methods

The choice of paint application method is based on the following factors:

- trunk length;

- pipe diameter;

- property location;

- the number of lines located together;

- industrial sanitation requirements;

- requirements of life safety rules and industrial safety techniques in this industry;

- convenience of staff;

- object lighting conditions;

- conditions of transparency of the air environment and visibility at the facility;

- ensemble of terrain or general architectural design.

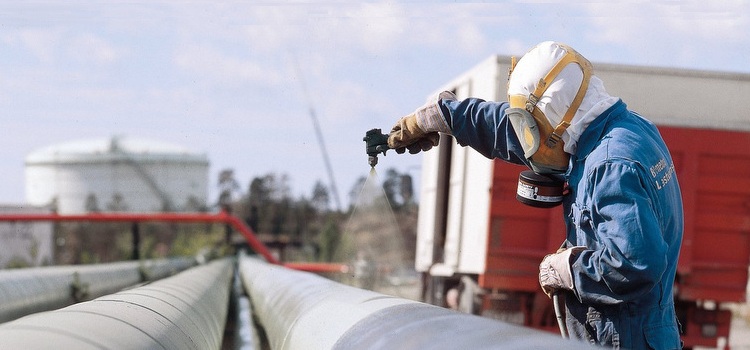

The method of applying a color coating may be different, depending on the type of paint, the location of the pipes and other factors

On a note! In workshops with a large length of communications and with a large number of them, and also, if for some reason the concentration of bright colors is unacceptable, marking is applied in areas. With a small length of communications, there are a small number of communications, and if this does not lead to a deterioration in work in industrial premises, the painting is continuous.

A continuous layer is applied to outdoor objects, taking into account the effect of solar radiation and other weather factors on the coating.

If the coating is applied in production rooms and workshops in areas, then the rest of the pipe surface is usually painted in the same color as the walls of the room. However, to fill the gaps, using other marking shades is strictly prohibited.

Another important rule is as follows: the application of areas of the marking coating should be carried out taking into account the characteristics of a particular region: solar activity, weather, visibility, climate. At the same time they are located in the most critical places. These include connections, branches, sampling and instrumentation points, points of passage of pipelines through walls, partitions, ceilings, as well as inputs and outputs of production facilities.

How to calculate the amount of paint

First of all, it should be said that there are no general norms of paint consumption for pipe painting. The reason is that each coloring material is characterized by its density, viscosity, list of ingredients and other properties. However, the estimated paint consumption per 1 square. The surface meter is indicated on the tank in which it is sold. It must be remembered that 2 layers are required.

Thus, the calculation is reduced to solving a simple mathematical problem of determining the surface area of a pipe.

From the stereometry course of high school, it is known that the value of this cylinder parameter, which, in fact, is any tube product, is calculated by the following formula:

S = π × D × L, where

π is the mathematical constant; D is the pipe diameter; L is the length of the pipe.

As an example, we will calculate how much paint is required with a flow rate of 250 g / m2 for two layers with an external diameter of the pipe of 30 mm and its length of 10 meters.

The surface area of the pipe will be: 3.14 × 0.03 × 10 = 0.942 m2.

Each layer will require 0.25 × 0.942 = 0.2355 kg of paint. And for approximately two, 0.471 kg of coloring material will go away.

Of course, the example is far-fetched. After all, knowing how to paint a pipe indoors, the owner will not waste time calculating thousandths of a gram. However, this approach is suitable for large pipelines.

Gas pipe painting

First of all, it is worth remembering that paint for coloring gas pipes serves as their corrosion protection.

Advice! Therefore, having calculated the required amount in the above way, purchase it with a margin, since it is not worth saving in this case. Moreover, there are no standards for the consumption of coloring material.

And one moment. Modern paint used for gas pipes usually has a specific name. A simple layman sometimes does not understand him. The fact is that on the unit label of this product the word “paint”, as a rule, is absent. To give you an idea of what is at stake, below are the most popular coloring materials to date that can be used to paint a gas pipe.

For the painting of metal pipes, special compositions with additives that prevent corrosion are used.

- Zinconol. This is a one-component polyurethane primer for metal filled with zinc.

- Epostat - epoxy chemically resistant primer-enamel.

- Polyurethol - polyurethane oil and petrol-resistant primer-enamel.

- "Nerzhahim" - chemically resistant soil-enamel.

Returning to the conversation about how a gas pipe is painted, it should be noted that this procedure is no different from painting any other metal pipe. But there is one caveat: when removing the old layer of the coloring material, it is forbidden to use heating devices.

Regardless of which paint is used for gas pipes, the painting steps are identical:

- wrap the treated area in rags previously soaked with washing. After 20 minutes, remove the softened paint with a spatula;

- clean the gas pipe with a wire brush from the old layer and rusty accumulations;

- apply a degreaser over the pipe. Information on its consumption rates per 1 sq. Km. m is indicated on the label of the bottle;

- color the pipe.

At the same time, observe the unshakable rule for gas pipes: paint is applied to them in two layers with intermediate drying. So you provide the pipeline with long-term coverage.

And in conclusion, some information about how the pipe with condensate is painted. Two options are possible here.

- If the dead-end branch from the central riser “sweats”, through which water is supplied to the sink or bathtub, simply turn off the tap on the riser and wait until the pipe warms up. After that, dry its surface, and, making sure that there is no condensation, paint the pipe according to the above technology.

- With the transit branch, the situation is more complicated. Here you need to follow the advice of home masters. If the condensate does not bother you much, you can wait for the water to shut off throughout the house and, without wasting time, after drying the pipe, quickly paint it with quick-drying paint.

It is necessary to paint the pipes taking into account their type, manufacturing material, purpose, etc. And the paint itself must meet the characteristics of the processed engineering communications.