Currently, polyethylene (PE) pipes are used to create high-quality and inexpensive water supply and sewage systems. These products confidently displace metal, asbestos cement and other analogues. Regulates the production of polyethylene pipes GOST 18599 2001. This regulatory document also contains technical standards and requirements for the final product.

Content

- 1 Features of polyethylene pipes

- 2 State standards and their requirements

- 3 Brand Differences

- 4 Advantages over Steel Pipes

- 5 SDR indicator of polyethylene pipes

- 6 HDPE pipes

- 7 Cross-linked polyethylene and the advantages of pipes made from it

- 8 Welding of polyethylene pipes

- 9 Design features of equipment for welding HDPE pipes

Features of polyethylene pipes

All polymer pipes have common technical and operational characteristics. However, despite this, certain types of products of this type have their own characteristics. The distinctive properties of PE products include: the warranty period for the operation of the polyethylene pipe GOST 18599 2001 is 50 years and the improvement over time of the properties for transporting the working medium.

The throughput of a polyethylene pipeline increases for two main reasons:

- The boundary layer of the polymer swells over time. As a result of this, a specific effect of surface elasticity arises, due to which the resistance to movement is reduced, and the flow conditions around the pipe walls are improved.

- Corrosion overgrowing of a metal pipe leads to a decrease in its inner diameter. However, due to the characteristic creep properties of polyethylene, the bore of a product made from this material during operation increases without sacrificing its performance. In figures, the increase looks like this: about 10% during the first 10 years and about 3% over the entire life of the pipeline.

A wide range of operating temperatures is another important advantage. A polyethylene pipe that meets the requirements of GOST 18599 2001 does not lose its operational characteristics at a significant negative temperature (-70 ° C) and retains its strength at + 60 ° C. When this mark is exceeded, the strength of PE decreases, and it loses its ability to withstand high pressure.

Resistance to high pressure and low temperatures allows the use of polyethylene pipes for laying underground networks without any insulation

The coefficient of decreasing the value of this parameter made of polyethylene pipes depending on the temperature of the working environment is presented in table No. 1.

Table 1

| Liquid temperature, ˚С | Pressure Reduction Ratio, Ct. | ||

| PE 100, PE 80 | PE 63 | PE 32 | |

| 36-40 | 0,74 | 0,62 | 0,3 |

| 31-35 | 0,8 | 0,72 | 0,47 |

| 26-30 | 0,87 | 0,81 | 0,65 |

| 21-25 | 0,93 | 0,9 | 0,82 |

| Less than 20 | 1,0 | 1,0 | 1,0 |

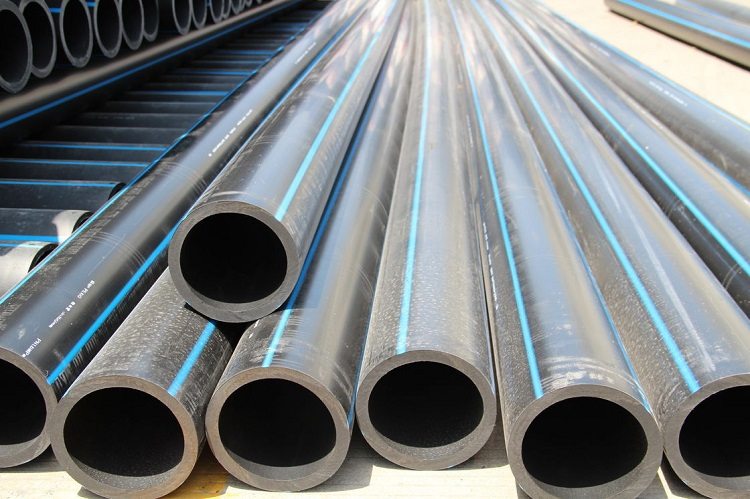

The elasticity of the pipes, in addition to ease of installation, has a positive effect on the transportation of these products. Pipes with a diameter of not more than 160 mm can be delivered to the consumer by bays of more than 200 meters in length. You can cut them with an ordinary hacksaw. Engineering networks are assembled from such pipes using special couplings, fittings, and other parts.

Important! Exposure to direct sunlight causes the aging of polyethylene. Therefore, in external communications should be used pipes made of polymer stabilized with soot.

State standards and their requirements

Technical characteristics of polyethylene pipes are regulated by the following regulatory documents:

- GOST 18599 2001. It contains requirements for pressure PE pipes used for transporting water (including drinking water) with a temperature of 0≤T≤40 ºС. This GOST does not apply to pipe polymer products intended for the movement of combustible gases and for electrical work.

- GOST 22689 89 describes the characteristics of pipes and fittings made of them from LDPE and HDPE (these abbreviations mean, respectively, high and low pressure polyethylene). Only those products that are used in the internal sewage systems of structures with a maximum constant temperature of effluents of +60 degrees and short-term (up to 1 min.) +95 адаютС fall within the scope of this standard.

Pipes with thick walls and with a large diameter do not fold into coils, but are delivered only in straight lengths of standard length

Melt flow, determined from the material of the finished product, should be no more than 2g / 10 min. The surface of the pipes should be smooth and even. On the outer surface, traces of a size not exceeding 0.5 mm from the calibrating and forming tool are allowed. Pipes of this type cannot be rolled into coils. GOST 22689 89 does not regulate deviation from straightness.

After heating the pipes, the change in their dimensions in the longitudinal direction should not exceed 3%. These products should not crack in a 20 percent solution of the auxiliary substance OP-10 specified in GOST 8433 81, within 24 hours after heating to 80 ± 3 degrees. The connection of PE pipes GOST 18599 2001 with fittings will be considered leakproof if it successfully passes the test with an internal hydrostatic pressure of 1 kgf / m2 (0.1 MPa) at a temperature of +15 ± 10 degrees. Pipes, as well as fittings, must be produced from HDPE melt with a yield index determined by GOST 16338. If LDPE is used as a raw material, then the value of this parameter is regulated by GOST 16337. In generalized form, the range of yield index values is 0.25≥ PT ≥1 ,5. Unit of measurement - g / 10 min.

GOST R 50838 from 1995 provides for the production of polyethylene gas pipes in bays, straight sections and on coils. But with one clarification: products with a diameter of 225 and 200 mm are produced exclusively in segments, the length of which can fluctuate in the range of 5 ≤L≤24 meters with a multiplicity of step of adjacent values of 0.5 m.The allowable deviation of the length from the nominal value is no more than 1 percent.

On a note! In one batch GOST 18599 2001 allows for pipes with a length of 5 3 ≤L ≤ 5 meters at least 5% of the total volume.

In relation to the manufacture of coils and coils, the indicator of the maximum deviation are as follows:

- pipe lengths up to 500 mm - no more than 3 percent;

- pipe lengths from 500 mm - not more than 1.5 percent.

The length of pipes supplied in coils may differ from the standard one by agreement with the customer

The production of polyethylene pipe products of a different length and with other extreme deviations is allowed only by agreement with the customer. The minimum long-term strength indicator depends on the type of product and is used in calculating the working pressure of the pipeline. Its designation contains 3 latin letters MRS, followed by numbers. PE 100 grade polyethylene is marked with MRS 10.0 MPa, PE 80 with MRS 8.0 MPa and PE 63 with MRS 6.3 MPa.

Brand Differences

For the first time, PE 63 was used for the production of polymer pipes. Its rather high short-term strength is not able to level the low resistance to cracking. In addition, with prolonged use, the strength properties of the material are significantly reduced. Therefore, at present, the production of pressure pipes from PE 63 according to GOST 18599 2001 has sharply decreased. Today, consumers consider products made of PE 80 and 100, the latter being the most demanded. This is due to the following factors:

- A higher density than PE 80 allows the production of pipes with a smaller wall thickness, without compromising the ability to withstand a given working pressure.

- The throughput is 20 percent higher and the pressure loss is 30 percent less than in a PE 80 pipe having the same nominal diameter.

- The weight of one running meter is 20% less than that of a PE 80 pipe that can withstand the same pressure. This factor provides a reduction in transportation costs and installation of pipelines.

- The indicators of resistance to fast and slow cracking are several times higher than these characteristics of similar products from PE 80.

- Higher frost resistance and resistance to various mechanical damages distinguishes PE 100 pipes.

- In the production of pipes of large cross-section from PE 100, a significant decrease in material consumption is recorded due to a decrease in the outer diameter without loss of throughput.

- Pipes of small diameter are mainly produced from PE 80.

Advantages over Steel Pipes

As mentioned above, a polyethylene pipe is guaranteed to last at least 50 years. Such a lifetime is possible due to the following properties of PE / pipes:

- lack of cathodic protection, which is why these products are virtually maintenance-free;

- high chemical and corrosion resistance. Pipes made of polyethylene are not afraid of contact with an aggressive environment;

- the possibility of scale formation on the inner surface is excluded;

- low thermal conductivity reduces the level of heat loss and reduces the formation of condensate on the outer surface;

- even if the liquid in the polyethylene pipe freezes, it will not collapse. The pipe will simply expand, and after thawing the working medium, it will return to its previous size;

- low modulus of elasticity reduces the risk of water hammer;

- welds of joints retain their reliability throughout the life of polyethylene pipes (GOST 18599 2001);

- butt welding is simpler, requires less time and much cheaper;

- multiple re-installation is possible;

- polyethylene pipe - a reliable shield against bacteria and microorganisms. Construction and reconstruction of engineering networks using pipe products of this type is cheaper by 40% compared to traditional methods.

Important! Polyethylene pipes weigh 5-7 times less than steel pipes. Therefore, the small movements necessary for their installation are carried out without the use of load-lifting mechanisms.

One of the main advantages of PE pipes is the ease of their installation both in the home and in industry

SDR indicator of polyethylene pipes

When purchasing such products, pay special attention to the markings affixed to them. It contains the following data for a specific pipe:

- information about the manufacturer;

- GOSTs, in accordance with the requirements of which it was manufactured;

- brand of polyethylene, for example, PE 100;

- the thickness of the material of the walls of the product and its diameter;

- the abbreviation SDR followed by a certain index. This is a strength indicator that provides the most accurate information about the capabilities of tubular products.

The abbreviation SDR comes from the English term Standard Dimension Ratio, which in the Russian translation sounds like this: Standard Dimension Ratio. Its value is calculated by dividing the outer diameter by the wall thickness of the polyethylene pipe GOST 18599 2001.

SDR = Outside Diameter / Wall Thickness.

A simple analysis of this formula says that products with a lower SDR index have thicker walls, and, conversely, a thin-walled pipe corresponds to a larger value of this index. Differences in the "pressure classes" of such products depending on the SDR are presented in table No. 2.

table 2

| SDR 41 | SDR 33 | SDR

26 |

SDR

21 |

SDR

17,6 |

SDR

17 |

SDR

13,6 |

SDR

11 |

SDR

9 |

SDR

7,4 |

SDR

6 |

| 4 atm. | 4 atm. | 5 atm. | 6 atm. | 7 atm. | 8 atm | 10 atm. | 12 atm | 16 atm | 20 atm | 25 atm. |

In general, this indicator along with the thickness of the polyethylene layer indicates what level of load or pressure (internal and external) a pipe made of polyethylene GOST 18599 2001 can withstand.

This standard dimensional coefficient is recommended to be used when determining the suitability of the pipe for the implementation of a specific system - pressureless and pressure, namely:

- pipes with SDR 6-9, in addition to water supply, are suitable for arranging pressure sewers and even gas pipelines;

- products indexed from 11 to 17 can be used to create low-pressure water and irrigation systems;

- polyethylene pipe products with indicators SDR 21-26 can be used to organize low-pressure intra-house water supply for multi-storey buildings. And, for example, pipes PE 100 with SDR 26 are used in the food industry: they transport juice, milk, beer or wine;

- pipes with SDR 26-41 are used for gravity (pressureless) sewer outlets.

Important! Accounting for the brand of polyethylene is one of the most important conditions for the correct choice of pipes made from it. Even with the same SDR, a product with a larger number in its labeling, for example, PE 100, rather than PE 80, will be more resistant to various mechanical influences.

The following are a few examples regarding the use of PE 80 grade pipes.

- Pipes PE 80 with SDR 21 are characterized by low resistance to internal pressure and compression. Therefore, it is not recommended to use them for the installation of a gas pipeline, digging into the ground and for pressure systems.

- Products PE 80 with an index of SDR 17 are recommended for equipping plumbing systems in low-rise buildings. For this, their strength level is quite sufficient. And save on installation will allow low weight and low cost.

- The PE 80 pipe with an SDR of 13.6 is very durable and can be used to build a long-term water supply system.

A pipe with a low strength indicator is suitable for use only in networks with low pressure, for example, in a watering system for a summer cottage

HDPE pipes

The main standards for pipes made of low pressure polyethylene are described in GOST 18599 2001.

Manufacturing technology. According to this regulatory document, for the production of these products it is necessary to use not any polyethylene, but only obtained during the polymerization reaction under low pressure. Its production is carried out in special chambers in which a constant value of this parameter is maintained in the range of atmospheres. A characteristic feature of the manufacturing process is also the stabilization of temperature around 150 ° C, and not just the control of the constancy of pressure.

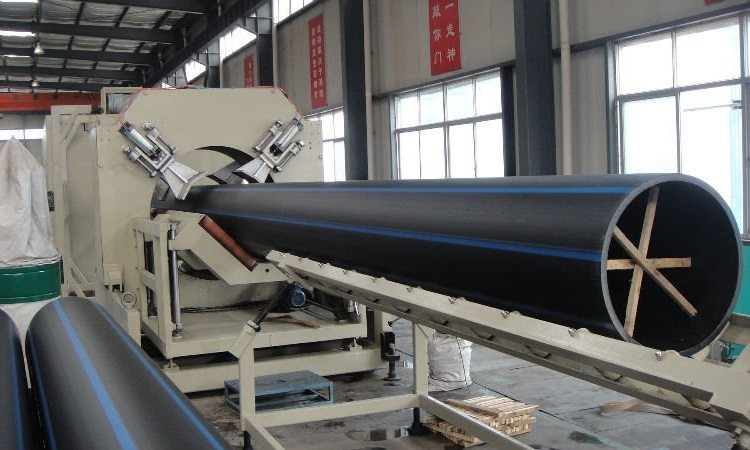

Today, two methods are used for the production of HDPE pipes GOST 18599 2001:

- Rotational mold technology. The tubular configuration is obtained due to the distribution of the molten polymer under the action of centrifugal force - it sticks to the surface of the walls of the mold.

- Extrusion. The product is made by extrusion from molten granules. The tubular structure in this case is formed by the head of the extruder: through it, the screw press pushes the superheated polymer. This process is easier to cast. However, in the first case, the dimensions of the PND pipes GOST 18599 2001 are more accurate and with minimal deviations from ovality.

As for the weight characteristics, their numerical value does not depend on the manufacturing technology. This is due to the absolute correspondence of the dimensions of the final product to the figures indicated in GOST 18599 2001. After all, the proportion of raw materials is the same in any case.

To get an idea of the mass of HDPE pipes depending on the diameter and SDR index, check out the data presented in table No. 3.

Table 3

| Diameter, millimeters | SDR 26 | SDR 21 | SDR 17, 6 | SDR 17 | SDR 13.6 | SDR 11 |

| 630 | 46 | 56,50 | 66,60 | 69,60 | 84,80 | 103,0 |

| 560 | 36,30 | 44,80 | 52,60 | 55,0 | 67,10 | 81,0 |

| 500 | 29,0 | 35,80 | 42,0 | 43,90 | 53,50 | 64,70 |

| 450 | 23,50 | 29,0 | 34,0 | 35,50 | 43,30 | 52,40 |

| 400 | 18,60 | 22,90 | 26,90 | 28,0 | 34,20 | 41,40 |

| 355 | 14,60 | 18,0 | 21,20 | 22,20 | 27,0 | 32,60 |

| 315 | 11,06 | 14,2 | 16,70 | 17,4 | 21,30 | 25,70 |

| 280 | 9,09 | 11,30 | 13,20 | 13,80 | 16,80 | 20,30 |

| 250 | 7,29 | 8,92 | 10,6 | 11 | 13,4 | 16,2 |

| 225 | 5,880 | 7,290 | 8,550 | 8,940 | 10,90 | 13,20 |

| 200 | 4,680 | 5,770 | 6,780 | 7,040 | 8,560 | 10,40 |

| 180 | 3,780 | 4.660 | 5,470 | 5,710 | 6,980 | 8,430 |

| 160 | 3,03 | 3,710 | 4,35 | 4,510 | 5,5 | 6,670 |

| 140 | 2,31 | 2,8 | 3,35 | 3,5 | 4,22 | 5,1 |

| 125 | 1,83 | 2,3 | 2,66 | 2.8 | 3,37 | 4,1 |

| 110 | 1,42 | 1,8 | 2,1 | 2,16 | 2,6 | 3,14 |

| 90 | 0,969 | 1,2 | 1,4 | 1,5 | 1,8 | 2,12 |

| 75 | 0,668 | 0,82 | 0,97 | 1,01 | 1,230 | 1,46 |

| 63 | 0,488 | 0,573 | 0,682 | 0,72 | 0.87 | 1,05 |

| 50 | 0,308 | 0,37 | 0,44 | 0,449 | 0,55 | 0,663 |

| 40 | — | 0,24 | 0,281 | 0,293 | 0,353 | 0,43 |

| 32 | — | — | — | 0,193 | 0,228 | 0,277 |

| 25 | — | — | — | — | 0,147 | 0,168 |

| 20 | — | — | — | — | — | 0,116 |

Advice! If you intend to use products of this type for hot water supply, pay attention to their markings when purchasing. It should contain the following sequence of letters: PE-RT.

Cross-linked polyethylene and the advantages of pipes made from it

In recent years, low-temperature heating systems have become particularly popular. This phenomenon is due to the appearance on the market of relatively cheap and reliable cross-linked polyethylene pipes.

This material is the most dense modification of the ethylene polymerization product, characterized by a network molecular structure, reinforced by additional intermolecular bonds. It is indicated by the following Latin letters: PEX. The first two, as you might guess, stand for polyethylene, and the last - X - just says that it is cross-linked.

Ordinary polyethylene is a collection of large polymer molecules with numerous side branches, most of which “float freely” in intermolecular space. “Crosslinking” forms additional bonds, which in turn create an especially strong structure — an intermolecular network similar to the crystalline lattice of solids. The use of various “crosslinking” technologies allows one to obtain a substance with a smaller or larger number of such bonds and, accordingly, with lower or higher strength characteristics.

- Pex a - characterized by the highest percentage of crosslinking. The number of crosslinked molecules can reach 85%. This peroxide polyethylene is obtained in the presence of hydrogen peroxide molecules.

- Pex b - the volume of the bound structure is 70%. Such a silane polymer is most widely used and is used in a wide range of commodity items sold on the modern market.

- Pex c - up to 60 percent of the molecules are crosslinked. It is made by a radiation method.

- Pex d - stitching reaches 70%. It is created in the presence of nitrogen molecules, and the reaction conditions are characterized by increased complexity.

By technical characteristics, cross-linked polyethylene is comparable to many solids. And in such parameters as the duration of operation and resistance to various destroyers, it even surpasses some of them. Of course, not all brands of cross-linked polyethylene can compete on equal terms with materials traditionally used for the manufacture of heating pipes and water supply. We are talking primarily about the product PEX-a. It is he who is characterized by the highest impact resistance, crack resistance and the highest melting point.

Due to the strength and high flexibility of PEX pipes, they are one of the best options for underfloor heating systems.

Helpful information! High percent crosslinking produces less ductile and harder products. This factor does not mean that it is the best. Just with its help you can get materials of different quality for the production of products for various purposes.

Based on the foregoing, cross-linked polyethylene pipes have the following advantages:

- shape stability. If such products will not be affected by an external load, they will not deform even at a temperature of + 200 ° C;

- high fatigue strength. This property is preserved during transportation of the working medium with a temperature of + 95 ° C;

- resistance to cracking. High impact strength and the same impact strength in places of incisions is fixed even at significant negative temperatures (-50 ° C);

- optimal ratio of flexibility and strength;

- the absence of heavy metal ions and halogens;

- resistance to corrosion;

- ability to withstand the effects of chemically active compounds;

- excellent shrink quality of the material;

- high wear resistance: the surface of the pipe made of cross-linked polyethylene is subject to attrition to a small extent.

Welding of polyethylene pipes

Welding considered the most reliable way connections of elements of polyethylene pipelines. Knowledge of its methods will allow you to choose the most suitable equipment.

Butt welding. This method is applicable when the walls of the pipes are thicker than 5 mm, and their diameter of the products themselves exceeds 5 cm. The ends of the products are heated to the required viscosity due to contact with the heating element - the stove. After their joining, a very reliable fixation is obtained because the process of compound formation itself occurs at the molecular level. Butt welding technology is not difficult. Realize it with your own hands to any home master. However, one cannot do without a special unit for welding polyethylene pipes. If you do not plan to lay pipelines from such a polymer regularly, you can simply rent the device and not buy it.

The sequence of steps is as follows:

- place the ends of the pipes in the corresponding welding machine;

- install the aforementioned heating plate between them;

- we press the ends to it under slight pressure;

- wait until they melt to the required level;

- we reduce the pressure and let the elements finally warm up;

- take out the stove;

- we connect both pipes under pressure;

- wait for the joint to cool and the joint to solidify.

Important! Perform manipulations with the stove as smoothly and accurately as possible. Otherwise, you risk violating the formation sites between the heated elements of molecular bonds.

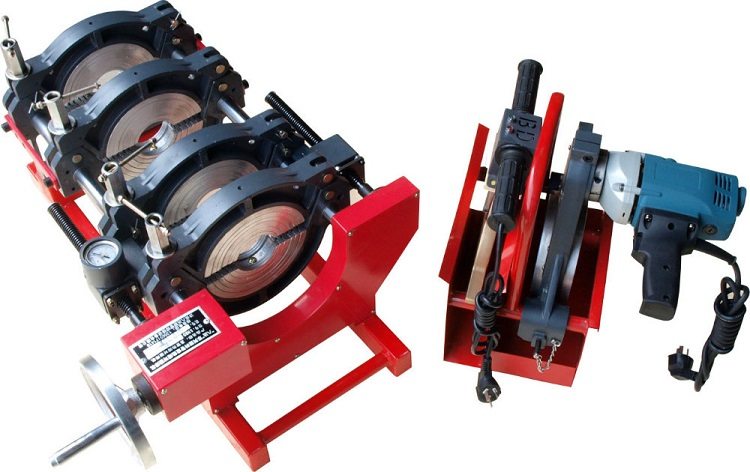

Today in construction stores you can purchase the following types of welding equipment for welding polyethylene pipes:

- welding machine on a mechanical drive. It involves carrying out all the actions manually;

- units with hydraulic drive. Thanks to hydraulics, less effort is required here;

- modern software-controlled devices. Being fully automated, these devices will significantly speed up, and most importantly facilitate the process. Of course, their cost is very high.

Experts note the following advantages of butt technology:

- mistakes due to inexperience and the human factor as a whole are excluded. As a result, the connection is very high quality;

- process automation (this applies to hydraulic and software-controlled equipment for welding polyethylene pipes);

- possible control during the execution of work.

Butt welding of polyethylene pipes will be high-quality and reliable with the correct implementation of all stages. The data of experiments conducted by independent organizations indicate that the strength of a correctly formed weld is 8 (!) Times higher than the similar characteristic of the pipes themselves.

The rules that must be followed when butt welding are very simple.

- Work should only be done on flat and hard surfaces, for example, on a reinforced concrete base, asphalt or boards. An important point is compliance with pipe alignment. The deviation of the axes should not exceed 10 percent of their wall thickness.

- Plugs should be inserted at the back ends. This ensures the absence of draft in the cavity of the pipes and the constancy of the set temperature of the butt welding.

- Before fixing the ends in the clamps, wipe them inside and out with a lint-free cloth. Perform a similar procedure with the clamps of the centralizer

- Fix the pipes in the chassis so that their marking is located along one line and is on top.

- Wipe the welding equipment before starting work. Carrying out a test joint will remove dust and microparticles from the heater. When working with pipes whose diameter exceeds 180 mm, perform two test joints.

- Before welding pipes with a different diameter, allow the heater to cool, and then make an additional test joint.

- You should only start a new connection when you are convinced of the alignment of the already connected pipeline segments.

- Grinding joints is preceded by a procedure for cleaning the grinder disks from particles of polyethylene that have previously adhered to their surface.

Important! Remove chips from the ends and the chassis with a non-metallic stick. Hands are strictly forbidden to do this.

Electrofusion welding. This method involves the use of a welding unit and special electrofusion. It is relevant for the installation of long pipelines, when butt welding is impossible to perform.

The work must be carried out in the following sequence:

- workplace preparation;

- selection of a suitable fitting;

- cleaning of connected parts from pollution;

- trimming the ends of the pipes with the subsequent removal of the oxidized layer;

- fixing polyethylene pipes and fittings in a positioner device;

- turning on the welding unit and waiting for the end of the operation;

- upon completion, turn off the equipment and check the quality of the seam.

During visual inspection, pay special attention to the following points:

- the edge of the seam should protrude above the outer and inner surfaces of the pipes in the form of a roller;

- the optimal height of these rollers is about 2.5 mm with a wall thickness not exceeding 5 mm. This indicator for more massive samples is no more than the same 5 mm;

- the displacement of the pipes should not be more than 0.1 percent of the wall thickness.

The design and dimensions of the welding machine required for installation work depend on the diameter of the PE pipes

Under these conditions, the connection will last for more than a dozen years.

Design features of equipment for welding HDPE pipes

The welding machine consists of the following three main components:

- bed. It has a centralizer for clamping, with the help of which the necessary force is created at the ends of the pipes. This element can be driven by a hydraulic (using a special device) and mechanical (i.e. manually) drive;

- trimmer electromechanical type. Designed to align the ends of the pipes immediately before the heating procedure;

- a heating element. In the slang of professionals, it is called nothing more than a frying pan. With its help, the ends of the pipes are heated and melted.

It was said above that today there are several types of equipment for welding HDPE pipes. Their features are as follows:

- the use of installations with a hydraulic type drive allows butt welding of pipes of almost any diameter;

- units with a mechanical drive. Such equipment makes it possible to butt-weld pipes with a cross section of up to 160 millimeters. It is characterized by one of the best price / quality ratios;

- welding mirrors. With their help, a very inexpensive welding is obtained. But in view of the fact that the device does not have a crosscut and a centralizer, it is not worth using it for welding pressure pipelines.

The following units are most popular.

NOT200. This heating device allows you to work with products with a diameter of not more than 20 cm. A high-quality connection provides an anti-stick coating.

R 63 E. It is used only in everyday life for welding any plastic pipes, including HDPE, whose diameter does not exceed 63 mm. Equipped with a temperature controller display.

ROWELD P 355. Designed for welding pipes with a diameter of 90 ≤ D ≤ 355 mm.

Helpful information! Due to its impressive dimensions, this model is mainly used in industrial production.

ROWELD ROFUSE BASIC. It is a household analog of the above unit.It is characterized by the ability to control any stage of work and is characterized by the highest safety.

Of course, this is not a complete list. The richest product range in this segment of the domestic market will allow you to choose a sample that suits your conditions.