The dimensions of modern metal pipes are determined by the method of manufacturing these products. The parameters underlying the production technology affect the final shape and other geometric characteristics of metal parts. There are several important geometric parameters, in accordance with which the operational area of pipe products is determined.

Content

Varieties of metal pipes

Today, the production of pipe products can be divided into two main components:

- production of metal products;

- production of plastic products.

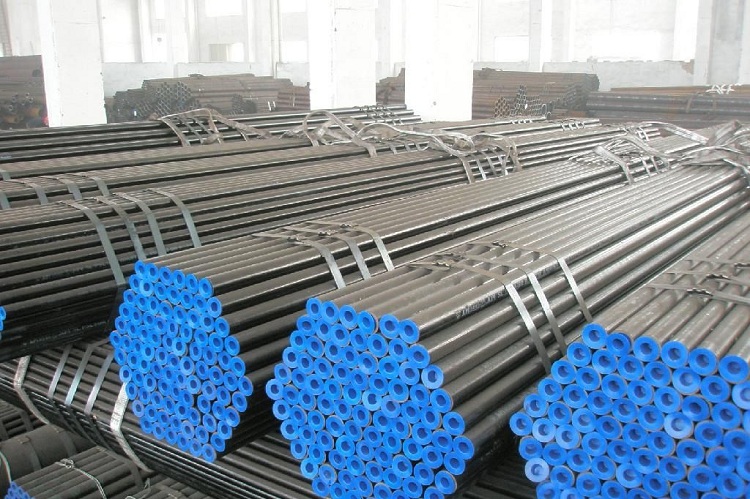

Metal pipes primarily differ in the material from which they are made. Consider the main materials used for the production of metal pipe products:

- black steel;

- stainless steel;

- cast iron;

- copper;

- aluminum.

Black steel is an alloy of iron and carbon and is made without mixing any binding elements. Such steel has a fairly low resistance to corrosion. A stainless steel is obtained by mixing iron, carbon and an alloying element - zinc. Stainless steel products have good resistance to corrosion. Cast iron is an alloy of iron and carbon, where the carbon content exceeds 4%. Copper and aluminum are non-ferrous metals that are resistant to corrosion and are characterized by high ductility and thermal conductivity.

Helpful information! For parts made of different materials, there are different standards that describe the ratio of the above parameters and are necessary for the minimum cost of resources in the production of metal pipes. Such standards are regulated by relevant documentation (GOST).

Each of the above materials determines the characteristics of the product. Therefore, regardless of other factors, the main parameter that determines the future geometric parameters and the operational area of the pipes is the material of manufacture.

The main parameters of metal pipes

Consider the most important parameters that affect the operational area of pipe products:

- nominal diameter (DN). The characteristic of pipe products, which is calculated in millimeters and characterizes the internal indicator of the section of the part;

- nominal diameter (days);

- external indicator of the cross section of the product. It is calculated in millimeters and allows calculations related to the outer surface of the pipe. Such calculations include: determination of the amount of heat-insulating material, paint, etc .;

- length of the product. It is calculated in meters and is a very important parameter that is used to calculate the number of parts when installing pipe structures;

- wall thickness. As a rule, this characteristic depends on the nominal diameter of the products. Most often it is used in hydraulic inspections of pipe products.

According to the outer diameter, pipe metal products are classified into three main groups:

- Small ones.The external section of these parts varies from 5 to 102 mm.

- Medium. With indicators of section from 102 to 426 mm.

- Big ones. Having a cross section exceeding the figure of 426 mm.

The ratio of parameters should take into account the normal operation of pipe products in the future, without compromising its technical characteristics.

Dimensions of steel metal pipes

The dimensions of steel and cast-iron pipes primarily depend, as mentioned above, on the production method. Consider two methods for the production of steel products by rolling:

- hot rolled;

- cold rolled.

Hot rolled parts differ in the following geometric characteristics:

- The external cross-sectional index varies from 20 to 550 mm.

- The outer section of the profile, as a rule, ranges from 60 to 180 mm. Calculation is performed on the verge.

- The wall thickness of hot rolled steel parts varies from 2.5 to 75 mm.

- The minimum length indicator of hot-rolled products is 4 m, and the maximum reaches 12.5 m.

Pipes that were obtained by cold rolling have the following geometric characteristics:

- The external indicator of the cross section is from 5 to 250 mm.

- The outer section of the profile varies from 10 to 120 mm (on the edge).

- The wall thicknesses of the products can be from 0.3 to 24 mm.

- A pipe that was obtained using the cold rolling method may have a minimum length of 1.5 m. The maximum length of such a part may be 11 m.

Such dimensions are inherent in pipe products, which were made of black steel. Stainless steel products are distinguished by their individual geometric characteristics:

- Indices of the external section of rolled products vary from 5 to 273 mm.

- The minimum length of such products is 1.5 m, and the maximum is 25 m.

It is also worth paying attention to the method of producing pipes, which is called folding. The dimensions of products manufactured using this method, followed by welding of the joint, depend on the type of weld. Depending on the type of weld, these pipes are distinguished:

- straight-seam;

- helical.

Consider the basic geometric parameters that are characteristic of longitudinal pipe production:

- The outer cross-sectional index of longitudinal joints varies from 10 to 1420 mm.

- The outer section of the profile has such dimensions - 10–230 mm (along the edge).

- The wall thickness index ranges from 1 to 32 mm.

- The minimum length of a straight-seam pipe is 2 m, and the maximum is 12 m. If the pipe cross-section is less than 70 mm, then the length can reach a larger figure.

Spiral metal products, in turn, are distinguished by such geometric parameters:

- The external cross-sectional index varies from 159 mm to 2520 mm.

- The wall thickness indicator ranges from 3.5 to 25 mm.

- The minimum length of spiral pipe products is 10 m, and the maximum is 12 m.

As in the case of rolling pipes, such geometric parameters characterize products that were made of black steel, and stainless steel parts have other dimensions:

- the cross-sectional index of stainless steel pipes varies from 8 to 102 mm.

- the minimum length of stainless pipes is 5 m and the maximum is 9 m.

Note! The dimensions of thin-walled metal pipes made of galvanized steel, as a rule, are adjusted to the needs of consumers. This is due to the fact that thin-walled pipes have geometric characteristics that directly depend on the dimensions of the steel billet (sheet).

Dimensions of cast iron metal pipes

Compared to steel pipes, cast-iron parts for the installation of communications do not differ in such a range.For the manufacture of cast-iron pipe products, only one method is used - rolling. Consider the basic geometric parameters of cast iron products obtained by rolling:

- The external index of the pipe section varies from 50 to 150 mm.

- The wall thickness of cast iron can be from 4 to 5 mm.

- The minimum length of cast-iron pipes is 0.75 m, and the maximum does not exceed 2.2 m.

The above geometric characteristics determine the operational area of cast-iron pipes. As a rule, such products are used for the installation of sewer communications. In most cases, sewer lines made of cast iron are pressureless (gravity-fed). This means that they divert waste water from consumers without the participation of special pumping equipment.

Sizes of non-ferrous metal pipes

The geometric dimensions of non-ferrous metal pipes are the same as in the case of steel pipe products. Copper pipes can be made in two ways:

- rental;

- welded method.

Rolled copper products as well as welded products differ in the following geometric characteristics:

- The outer section of copper products ranges from 3 to 360 mm.

- The outer section of the profile can be from 30 to 280 mm (on the edge).

- The wall thickness index, as a rule, is from 0.8 to 10 mm.

- The minimum length of copper parts is 1 m, and the maximum does not exceed 10 m.

The mass of copper pipes is directly dependent on its size and wall thickness. Thus, the more metal is spent on the production of the product, the more it weighs. Aluminum pipes, in turn, are made using two main methods - pressing and folding.

Consider the geometric parameters of aluminum pipe products obtained using the pressing method:

- The cross section of such pipes varies from 18 to 240 mm.

- The wall thickness can be from 1.5 to 40 mm.

- The minimum length of such products is 1 m, and the maximum does not exceed 6 m.

The second production option is used if it is necessary to obtain a corrugated pipe made of aluminum. The main geometric characteristics of the corrugated pipe: the cross-sectional indicators of corrugated aluminum products vary from 80 to 310 mm, the length is determined directly by the manufacturer.