Seamless steel pipe - products of continuous pipe metal rolling, which are produced on special pipe rolling mills. It has significantly higher rates of resistance to external influences, strength and reliability than similar welded structures. Despite the spread of polymer products, it is still in demand in the construction of pipelines, construction, engineering and other areas.

Seamless pipes have high strength characteristics and are in demand in a wide variety of industries.

Content

How to make seamless pipes

Industrial enterprises produce seamless pipes using various combinations of metals and alloys, depending on the purpose of the product. Production is carried out by four main methods:

- By drawing.

- Forging.

- Pressing.

- By rolling.

Products used as starting material for hot-deformed pipes can be:

- forged blanks;

- continuously cast billets;

- prepared pipe billets;

- bars of open-hearth rolling.

Seamless hot-deformed steel pipe is produced by performing several technological operations.

At the initial stage, the rod, a round workpiece in cross section, is converted into a sleeve. This is done with the help of presses or special mills with mushroom, disk or conical rolls. The workpiece is guided along the axes, processing is performed by working tools rotating in one direction, located in a vertical plane with an inclination of 4-12º. During processing of the workpiece, its cross-sectional area is reduced and a small hole is formed in the axial part.

A special mandrel installed between the rolls adjusts the hole sizes of the product and smoothes its surface. At the same time, with special guides and non-conductive rollers, the workpiece is held in the desired position. Carrying out the initial heating of the workpiece to 50º C, they give it the plasticity required for processing.

On the rolling mill, the dimensions of the finished sleeve are again subject to adjustment. Before transferring to the final run-in, parameters of difference and ovality are set for it. After which the product is in a continuous hot rolling mill, from where it goes to a cold calibration

Cold-formed products, characterized by high quality, are thoroughly processed. Even at the preparation stage, careful selection of blanks is carried out. Further preparation for processing involves an annealing procedure. Annealed, the raw material enters the etching - acid treatment. To neutralize the effects of etching and cleaning of its residues, the pipe is treated with an alkaline solution, and then dried. To further improve the properties of the pipe, phosphating or copper plating is carried out.

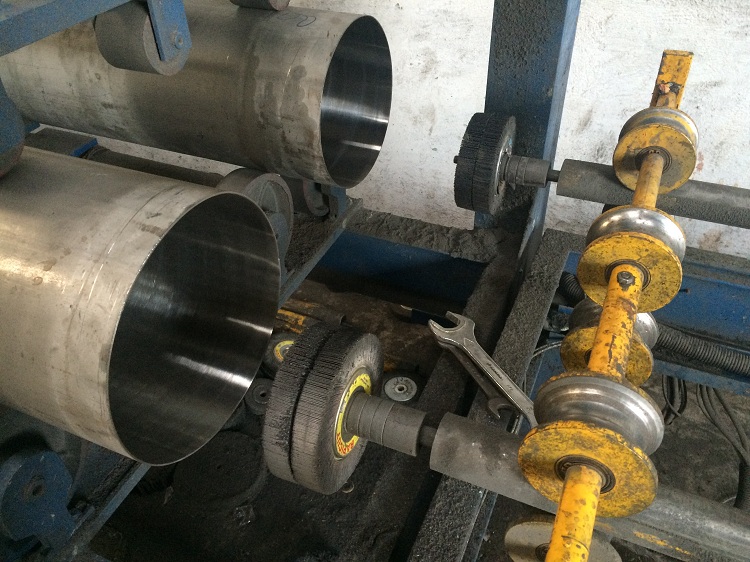

On a rolling mill made up of a rolling stand and two rolls located at a given angle and rotating in opposite directions, a caliber is formed. The dimensions of the caliber in the direction of increase or decrease are set by changing the angle of inclination of the rolls. When the rolling mill moves to the workpiece, the latter is between the rolls. And when the direction changes, compression occurs. During one rolling process, dimensions such as the diameter and wall thickness of the pipe are changed. By producing thin-walled products, the process is duplicated, again annealing and pickling the workpiece. After this comes the final finish of the product.

Seamless steel pipe classification

Products are distinguished, first of all, by the method of pipe rolling, depending on what they can be:

- hot deformed (hot rolled). The release of such products is regulated by GOST 8732-78;

- cold deformed (cold rolled). The range is specified by GOST 8734-78.

GOST sets the possible dimensions of the produced pipes, and the seamless weight of the pipe depends on its diameter and wall thickness. In relation to length, it is distinguished (data are shown only for thick-walled pipes):

- measured - 4.5 - 9 m;

- unmeasured - 1.5 - 11.5 m;

- multiple measured - 1.5 - 9 m, adding a five-millimeter allowance for each cut.

The ratio of the dimensions of the outer diameter and wall thickness defines the division of seamless products into three types. They may be:

- Particularly thin-walled.

- Thin-walled. The diameter value is greater than the value of the wall thickness from twelve and a half to forty times.

- Thick-walled. Six to twelve and a half times.

- Especially thick-walled. Up to six times.

Thick-walled and especially thick seamless pipes are usually subjected to additional heat treatment to give additional resistance to pressure of the working medium of the main pipeline or other communications.

According to their quality characteristics, hot-rolled seamless products are divided into five groups, denoted by letter indices:

- A - with normalized properties of a mechanical nature;

- B - with a normalized chemical composition;

- B - with the product of control over the properties of a mechanical nature and chemical composition;

- D. The chemical composition is normalized, and the properties of a mechanical nature are subjected to a control procedure for which samples are provided.

- D. In relation to the properties of a mechanical nature and chemical composition, rationing is performed, supplemented by the hydropercussion test procedure for thick-walled products.

Steel pipes are divided into six classes, taking as a basis the purpose of the product:

- 1st. Standard and gas pipes are used when laying irrigation systems and cable lines, enclosing an object with fencing and scaffolding, locally supplying and / or distributing liquids and gaseous mixtures.

- 2nd. They equip the main pipelines through which water, gas, oil and oil products, fuel and solids are transported as a pressurized working medium.

- 3rd. Demanded by systems whose work is associated with high temperature conditions and high pressure of the working environment.

- 4th. They are used in oil exploration and oil production casing, drilling and auxiliary.

- 5th. They are involved as elements of large-scale steel structures such as masts, supports, drill rigs and bridge cranes. They are used by transport engineering as construction pipes. Involved in the manufacture of furniture in the form of its elements.

- 6th. They are operated by mechanical engineering, where they produce cylinders and pistons for pumps, rings of shafts and bearings of various units, and tanks for working under pressure. Depending on the outer diameter, they are divided into three groups.

The diameter of steel pipes can be:

- Small - up to 114 mm.

- The average is 114-480 mm.

- Large - from 480 mm.They produce seamless pipes with a diameter of over two and a half meters.

How to determine the weight of a seamless pipe

It is very important to determine the exact weight of a seamless hot-deformed pipe, since this product is sold to the consumer at a cost that depends on this value. Since it is precisely the value of the metal that sets the value of the products made from it. Using special metal calculators, you can make the necessary calculations for three parameters:

- masses;

- lengths;

- outer diameter.

For hot rolled products, the value:

- outer diameter is in the range of 25-700 mm;

- wall thickness - 2.5 -75 mm;

- measured length - 9-12 m;

- unmeasured length - 4-12 m.

The weight of the purchased batch of rolled pipe is calculated based on measurements:

- pipe thickness;

- lengths;

- outer and inner diameter.

The running meter weight can be viewed in accordance with GOST or calculated independently. To do this, resort to a simplified formula: P = 002466 * S * (D - S). In the formula:

- P - linear meter weight;

- S is the wall thickness;

- D is the outer diameter.

When determining the weight, it is worth taking into account the standard indicators of limit tolerances established for the dimensions of the pipes. With a length not exceeding six meters, up to ten millimeters of allowance is allowed. This value is increased by one and a half times with a larger pipe length and a diameter of more than 152 mm. With an approximate calculation of the length of the products, the maximum tolerance can reach up to half a meter.

For the outer diameter of hot rolled pipes up to 219 mm, the tolerances should not exceed one percent, with higher values the tolerance may be higher by a quarter.

For the wall thickness of a hot-deformed seamless pipe, the maximum tolerances are provided for about ten to fifteen percent.

The benefits and applications of seamless steel pipes

Speaking of seamless metal pipes, as a rule, they immediately indicate a high cost of products caused by the complexity of the production process. Nevertheless, a sharp increase in product quality, compared with welded pipe rolling, not only pays for expenses, but also brings significant profits to manufacturers due to the high demand for seamless pipes.

Seamless pipes are also in demand in the energy sector, heavy engineering and the chemical industry.

The same high demand is explained, which did not disappear with the spread of numerous varieties of plastic pipes:

- exceptional strength of products provided by wall thickness;

- a unique variety of assortment associated not only with overall parameters, but also with the use of various production technologies and steel grades.

Seamless branches are interested in many sectors of the economy, which are important, first of all, the special strength of the products. They apply:

- in the energy sector. Through seamless pipes, coolant is circulated in the boiler, and superheated steam is discharged to the turbine;

- in the aircraft industry. This industry requires predominantly strong and lightweight especially thin-walled products;

- in the chemical industry. Transportation of products in this industry must ensure that no leaks are possible, which is ensured by seamless steel pipes;

- in the extraction, processing and transportation of gas and oil. Not for main pipelines, where they are bypassed with steel pipes, but under operating pressure of hundreds of atmospheres;

- in the food industry. Demanded safety and ability to meet sanitary and hygienic requirements, environmental friendliness;

- in hydraulic systems where pistons and cylinders have to deal with pressures of hundreds of atmospheres;

- in construction.Colossal farms, supports and masts are being built with the expectation of many decades of excellent work, and quickly assembled and dismantled scaffolding can significantly accelerate the work.

Seamless steel pipes ensure the functioning of many sectors of the modern economy. Despite the proliferation of numerous plastic products, seamless steel products are highly demanded, and we are not talking about their ousting from the market in the near future. Moreover, the strength characteristics, reinforced by the use of various additives, make seamless steel pipes truly indispensable in many sectors of the economy, from aircraft to energy.