Cast iron pipes are mainly used for the installation of sewer structures. And even after the advent of more modern polymeric materials, cast-iron parts continue to be used everywhere. This is due to the fact that they have a long service life and are also able to withstand heavy loads during transportation of liquids.

Content

- 1 Advantages and operational sphere of cast iron pipes

- 2 Cast iron pipe production

- 3 Varieties of cast iron pipes according to GOST

- 4 Domestic sewage. Main characteristics

- 5 Domestic sewage. Quality Control and Labeling

- 6 External sewage. Main characteristics

- 7 External sewage. Quality Control and Labeling

- 8 Tips for installing and operating cast iron pipes

Advantages and operational sphere of cast iron pipes

Like any other product, cast iron pipe has its own advantages. Consider the advantages of cast iron parts over modern plastic:

- they are distinguished by high strength characteristics;

- cast iron pipes are wear resistant;

- cast iron has good soundproofing properties;

- parts from this material are fire resistant;

- are resistant to temperature fluctuations;

- have a low tensile coefficient.

Helpful information! These products are regulated by relevant state documentation (GOST). According to GOST, cast-iron parts for sewer networks are best used for installation inside structures in which the load exceeds economic standards.

Consider in which cases it is recommended to lay pipes made of cast iron:

- in industrial enterprises related to the food industry;

- at factory enterprises;

- on farms;

- in facilities equipped for sanatoriums (if there is an outlet for geothermal sources);

- in facilities equipped for health purposes;

- in educational institutions.

Cast iron pipes are very heavy, so their installation is quite time-consuming. Products with large cross-sectional indicators during installation require the use of special equipment.

Cast iron pipe production

Cast iron pipes are made by casting. Today, there are two varieties of casting for these sewer parts. Consider these two casting options:

- centrifugal;

- semi-continuous.

The first method involves the use of a special form. Cast iron is poured into it, after which, due to rotation, it is evenly distributed along the walls of the mold and as a result a finished part is formed. The thickness of the wall will depend on the amount of cast iron used.

Consider the main advantages of this method:

- high pipe production speed, which affects performance indicators;

- good quality of the cast iron product cast by such a method;

- saving raw materials and electricity;

- the ability to automate this method;

- simplification of the process associated with the lack of need for additional steps (molding and drying);

- Such a process saves not only time and money, but also space, since the need for additional equipment is eliminated.

However, centrifugal casting has its drawbacks. Among the disadvantages of this method are the following:

- the pipe can be made only in a certain shape, in accordance with the shape of the workpiece;

- the need for strict control of the amount of raw material entering the billet (to obtain the required wall thickness).

The method of semi-continuous casting involves filling the mold with molten iron. In this form, cast iron freezes and the finished product is obtained. After partial solidification, the part is removed from the mold and divided into the necessary segments. The cooling process is carried out using ordinary water.

Consider the main advantages of this method:

- using this method, you can get a long product, which is subsequently cut into parts of the required length;

- the accuracy of the geometric parameters of the product is maximum;

- the possibility of saving molten iron.

The disadvantages of this method include:

- not too high performance;

- the finished pipe is quite difficult to remove from the workpiece.

Varieties of cast iron pipes according to GOST

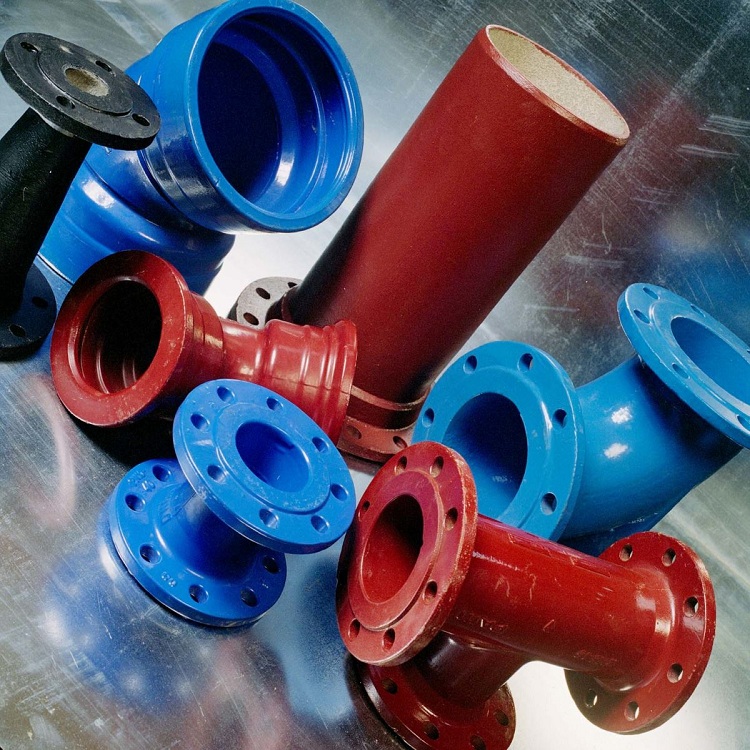

All pig-iron pipes according to GOST are divided into 4 types. Consider them:

- high-pressure ductile iron alloys (high-strength cast iron with spherical graphite) pipes along which the working medium moves under pressure. The necessary pressure indicators, as a rule, are pumped with the help of pumping equipment;

- non-pressure, which are used in the installation of sewer communications;

- socketless. Pipes that are produced without a connecting element - a bell;

- pressure head with a bell.

Pressure products are produced in a range of diameters from 100 to 300 mm. The spherical structure of graphite affects the main characteristics of such pipes:

- high resistance to harmful effects of corrosion;

- the life of the ductile iron tubes is 3-5 times higher than that of steel products 3-5 times;

- good resistance to temperature extremes;

- resistance to aggressive chemical compounds;

Helpful information! Ductile iron tubes have high strength characteristics, so they are often used when laying a pipeline under the roadway or at great depths in the ground.

Pressure ductile iron tubes can be connected in two ways:

- by means of a special rubber gasket;

- using a bell.

Pressureless pipes made of gray cast iron and used in the installation of sewer structures have the following characteristics:

- plastic;

- strength characteristics of these products are inferior to those of ductile iron tubes;

- reusability of use.

They, as a rule, are mounted in those places of the sewer structure where heavy loads are excluded. Pressureless sewer pipes are often used in combination with polymer products. Docking of cast-iron and polymer parts is carried out due to special rubber transition elements.

Socketless pipes are made of cast iron, which contains a lot of graphite. The inner walls of such parts at the production stage are treated with an epoxy compound. This procedure avoids salt deposits on the pipe walls, and also increases corrosion resistance. Consider other characteristics of socketless cast-iron parts:

- high sound insulation coefficient;

- fire resistance;

- high strength;

- resistance to high temperature indicators.

Docking of such pipes to each other is carried out by means of clamps, which allows to obtain a tight connection of two parts without the use of additional sealing materials.

Bell-shaped pressure products are highly corrosion resistant and are used for the installation of sewer lines. The main advantage of these parts is a long service life, and the main disadvantage is the fragility of cast iron material, which complicates the laying of sewers.

Domestic sewage. Main characteristics

Internal sewerage, which is made of cast iron parts, as well as auxiliary connecting elements is described by GOST 6942–98. This regulatory document governs all geometric dimensions, as well as the qualitative characteristics of these products and the rules for their operation.

According to GOST, their production without connecting sockets is permitted. However, socketless production must first be negotiated with the customer. With socketless production, care must also be taken to include connecting fittings in the delivery set.

The cross-sectional indicators of such products according to GOST can be:

- 50 mm;

- 100 mm;

- 150 mm.

The length of cast-iron pipes ranges from 75 cm to 2.2 m. The main parameters of the internal cast-iron sewer pipes are presented in table No. 1.

Table 1

| Mm | Length m | Weight, kg |

| 150 | 0,75-2,2 | 15,7-43,4 |

| 100 | 10,5-27,1 | |

| 50 | 0,75-2 | 4,5-1,1 |

In addition, the GOST indicates design features and sizes of shaped elements and other auxiliary spare parts. Consider these details:

- sockets;

- bends;

- branch pipes;

- tees;

- crosses;

- couplings;

- revisions;

- stubs.

Finished products should not contain any defects that could impair the performance of cast iron products. Defects include:

- growths on the walls of the pipes;

- drops of metal.

Spills on the outer walls of cast iron sewer pipes should not be deeper than 1 mm, and at the ends - deeper than 2 mm. The permissible differences in the cross-sectional indicators of cast-iron pipes and fittings should be no more than 2 mm, and the length deviations may not be higher than 0.9%.

Note! The mass of cast iron sewer pipes must correspond to a certain accuracy class. If the weight of the product exceeds the permissible indicator, then its operation is allowed only in one case - when other technical specifications comply with the standards.

After laying the pipes, the design must comply with all standards and must withstand the pressure indicators stated in the regulatory documentation. This rule especially applies to cast-iron parts, the pressure indicators of which should be no less than 0.1 MPa.

Domestic sewage. Quality Control and Labeling

Pipes for internal sewer communications are made of gray cast iron. As a rule, anti-corrosion compounds are applied to the inner and outer walls of such parts, the basis of which is bitumen. The bitumen composition can withstand temperatures up to 60 ° C. The service life of cast iron products for domestic sewage is from 80 to 100 years.

Quality control of pig-iron products for sewer networks is carried out at the enterprise. Such verification includes a number of stages and is carried out at special stands. The main indicator that these products must meet is tightness. The tightness test is carried out by filling the cast-iron part with water, and also by injecting the necessary pressure indicator (for example, 0.1 MPa). With such a check, the following phenomena are categorically not allowed:

- flow;

- condensation on the outer walls of the part.

The conformity of the geometric parameters of the products is checked by means of special tools that are able to provide the necessary measurement accuracy. Deviations from the norm should not be higher than specified in GOST.

Marking on pig-iron pipes for sewer communications is carried out on a bell. In some cases, marking is applied behind the bell. There are two marking options:

- The marking is applied with a special paint, which differs in that it cannot be washed off.

- Marking is cast on the product.

Marking must necessarily contain the following information:

- trademark;

- corresponding to GOST;

- vendor code.

After manufacturing, cast iron pipes for domestic sewage should be sorted into containers or bundles. Warranty for such products should be provided by the manufacturer for at least 2 years.

External sewage. Main characteristics

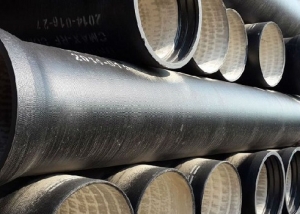

The dimensions of the cast-iron pipes used for outdoor sewer networks and the requirements put forward for them are set out in the relevant documentation ("Cast-iron sewer pipes GOST 9583–75"). According to this document, the cross-sectional indicators of pressure pipes for external sewer lines are from 65 to 1000 mm.

The main characteristics of the external sewer pipes made of cast iron are shown in table No. 2.

table 2

| Mm | Length m | Weight, kg |

| 1000 | 4–6 | 525,6–627,9 |

| 800 | 359,8–429 | |

| 600 | 4–10 | 222,9–266,6 |

| 400 | 118,5–141,4 | |

| 300 | 4–6 | 77,6–92,7 |

| 250 | 60,1–71,6 | |

| 200 | 44,6–52,9 | |

| 150 | 3–6 | 30,5–36,4 |

| 125 | 24,5–29,1 | |

| 100 | 18,9–22,3 |

The length of such products can vary from 2 to 10 meters. Outer sewer pipes made of cast iron are divided into 3 classes, depending on the wall thickness and, accordingly, on the mass:

- AND;

- LA

- B.

Deviations from the permissible norms for these pipes are:

- for the mass - 5% of the total.

- phosphorus content should be no more than 0.7%;

- sulfur content should be no more than 0.12%.

Note! Such pipes are made of gray cast iron, and their inner and outer walls must be treated with a special protective layer of environmentally friendly materials.

The surface of such parts must comply with all standards and exclude the presence of the following defects:

- dents;

- cracks;

- exfoliating areas.

External sewage. Quality Control and Labeling

The surface of cast iron parts used for the installation of external sewer lines must not soften at a temperature of 60 ° C. The tests to which pipes should be subjected are carried out after their manufacture directly at the factory and include a set of the following measures:

- test of strength;

- checking geometric parameters using special tools;

- hydraulic tests;

- hardness test.

The marking, as a rule, is located at the end of the socket and includes the following information:

- trademark;

- conditional section indicator;

- production date.

It is allowed to transport products with small cross-sectional indicators (up to 150 mm) in bags. The total mass of such a package should be no more than 3 tons. Storage of parts in this case should take into account their sorting into stacks. The surface on which such stacks are located should be flat. Each next row is recommended to be laid on wooden boards. The height of such a stack should be no more than 3 m above ground level. Side supports are recommended to reinforce such stacks.

Tips for installing and operating cast iron pipes

The main advantage of cast iron pipes over plastic is the noise insulation characteristics of the former. Their walls suppress any sounds that appear as a result of moving the working medium through pipes. However, the weight of cast iron products affects labor costs during the installation of sewer structures, which in any case affects the speed of all necessary installation work.

The specific service life of these products should be at least 50 years, however, in many sources, the shelf life can reach 100 years. In any case, in order to extend the service life of cast-iron sewer pipes, it is necessary to strictly follow all the rules for their installation.

It is very important to remember that ordinary cast iron is not recommended for use in structures that will transport aggressive chemicals. For such situations, it is better to use pipes with higher resistance to aggressive chemical compounds (for example, ceramic). However, there is a nuance here - for household sewage, laying of steel products will cost too much.

Important! To fill the free spaces at the joints of cast-iron pipes, it is recommended to use a special hermetic, which is called a heel. Kabalka is a plant fiber impregnated with tar-bitumen mastics, and in some cases - oil solutions. After filling the free spaces with heels, it is necessary to cover the joint with cement mortar.

It is not recommended to fill the joints of cast-iron pipes with sulfur, since it emits fumes harmful to human health when heated. In addition, sulfur is highly flammable and cannot be extinguished with water.