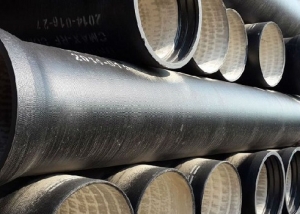

VChShG pipes are the best choice for arranging water supply and sewer systems. For the manufacture of using special high-strength cast iron with spherical graphite (hence the abbreviation VChShG). A cement-sand coating is applied inside the products. Such parts differ in performance for the better compared to both conventional cast iron (gray cast iron) and steel.

Content

ICF: what is it and what are its advantages

The patent on the ductile iron was granted to the American K.D. Millis in 1949. The spherical shape of graphite in molten iron made it possible to significantly change its properties. The new material turned out to be extremely profitable due to a combination of a number of parameters:

- physical and mechanical;

- operational;

- economic.

Ductile iron has successfully replaced gray cast iron due to its greater strength and ductility. Unlike steel, the new material practically did not crack and was slightly susceptible to corrosion. Its use instead of steel and non-ferrous metals allowed to significantly save on the cost of materials. The ductile iron proved to be inexpensive to manufacture. Other advantages that explain the distribution of material:

- resistant to cyclic loads;

- high ductility;

- lends itself well to cutting.

Good to know! Soviet GOST still operates on high-strength cast iron 7293-85. It extends, in addition to ductile iron, also to ductile iron, where graphite is presented in vermicular form.

Method of production and technical characteristics of ductile iron tubes

Gray cast iron has been used for laying pipelines and sewage systems since the mid-19th century. The durability of the material, as its main value, was reduced by the fragility of cast iron. And fragility was predetermined by the lamellar form of carbon (graphite). The use of casting using the magnesium process allowed to give graphite a spherical shape (oval, spherical). Gray cast iron is heated to a temperature of 1480-1538º C. The addition of special magnesium additives (ligatures) gives the graphite a spherical shape. The castings obtained after thermal tempering retain the advantages of ordinary gray cast iron:

- low susceptibility to corrosion;

- high compressive strength;

- resistance to cyclic loads.

In addition, high-strength cast iron has gained a number of advantages inherent in steel:

- impact resistance;

- tensile strength;

- elasticity;

- relative extension.

Small balls of graphite excluded the appearance of cracks and other defects during casting. New material got rid of the fragility of its predecessor. High-strength cast iron was malleable, ductile.

The production technology allowed the ductile iron pipes to get rid of the fragility, which greatly limits the use of such products

The inner coating of the ductile iron pipe made of cement-sand mortar creates an active and passive protective barrier. The solution layer isolates the internal walls of the product and provides passive protection. The process of cement hydration is an active defense.A saturated calcium hydroxide solution forms in the cement pores. A submicroscopic coating of iron oxides appears. It is insulated with cement mortar from the water stream and stops the corrosion process.

Cement-sand coating (CPP), applied to the inner side of the product, provides not only corrosion resistance. It has a positive effect on the hydraulic properties of pipes. The inner lining prevents deposits and deposits from forming. During the operation of the CPP, the effect of self-zonation (self-sealing) is noted. CPP is becoming more durable and dense. It better resists corrosion and provides a high permeability coefficient of fluid flow.

Protecting the inner surface from the effects of aggressive fluids, high-alumina (sulfate-resistant) cement is used. A CPP based on it provides high resistance to abrasion and abrasion. It exhibits significant resistance to chemical compositions.

Important information! The service life of ductile iron tubes is one hundred years. They are used when it is impossible to use structures from other materials due to technological, technical or economic indicators.

What technical characteristics led to the widespread use of ductile iron tubes? These include:

- high plasticity threshold (not less than 300 N / mm2);

- tensile strength (up to 420 MPa);

- elasticity (bending strength) - up to 270 MPa;

- elongation reaches 10% for DN 60-1000 mm and up to 7% for DN 1100-2000 mm;

- resistance to ovization (not subject to significant deformation);

- impact resistance.

Storage conditions

Sometimes there is a need to send cast iron ductile iron pipes for storage. Before sending for storage, the product should be checked. Detect external damage or defects in the internal coating - repair. Store in accordance with the general rules of storage of metal. Stacked in stacks in diameter on a flat surface. The stack should not exceed 2.5 m in height. It is imperative that the shelf life of cast iron pipes in the stack is minimized. Otherwise, cracks occur in the inner coating, and the service life of the product is reduced.

Mounting Features

High-strength pipes with spherical graphite are mounted by the method of sequential extension. In this case, the designed pipeline profile is strictly observed.

Pipes can be connected by successive extension when a flat edge of the next pipe is inserted into the socket of the previous

Important! If you need to shorten the pipe, then round off its smooth end. Or perform a chamfer of 5 x 30 °.

Before starting the installation, the outer and inner surfaces of the pipes and flange parts are cleaned of contamination, foreign objects. Devices for gripping and lowering the mounted joints in the trench should ensure the safety of parts of the pipeline. It is unacceptable that the products hit one another on hard objects in order to avoid deformations.

The sealing rubber ring in the annular groove allows sealing when the pipes are joined. For this, radial compression of the sealing ring is performed. Checks the correct placement of its crest.

Installation of ductile iron tubes for Tyton connection

It is convenient to determine the boundaries of the installation of the smooth end in the socket when using the socket connection "Tyton". To do this, a special mark is applied to the pipes. For other types of compounds, no special label is applied.

The inner surface of the o-ring and the outer surface of the smooth end of the cast iron pipe to a special mark is covered with a thin layer of lubricant. It is important to prevent grease from entering between the o-ring and the inside of the pipe.