Cold-deformed seamless steel pipes GOST 8734 75 and 78 are varieties of metal pipes. They are used in almost all sectors of the national economy, as well as in the decoration of premises and furniture industry. With many advantages, they do not lose relevance today. However, before using them for your own purposes, you should familiarize yourself with all the features of this product.

Content

Main characteristics

Today, the market of sanitary equipment can offer a mass of products that vary in individual technical characteristics, material, diameter, overall parameters, purpose and other criteria. Since the last century, metal has been a popular material for communication plumbing and sewer systems. Today it is also used for transportation and supply of gas, oil, chemicals, etc. Despite the fact that steel products began to receive tangible competition from plastic ones relatively recently, the former still do not lose their relevance, because in some cases they are simply irreplaceable.

Seamless cold-deformed steel pipes GOST 8734 78 are made of a special steel composition, which ensures compliance with the necessary quality standards and creates certain advantages over products from other materials.

This pipe has various characteristics and technical features, depending on the purpose, dimensions and other parameters.

The advantages of steel pipes

These steel seamless products have many positive qualities that cannot be ignored when choosing equipment.

Among them:

- universality. Pipes are used in almost all spheres of household and professional activities of a person, pipelines from them can be used in various types of buildings to transport almost any liquid and gaseous substances;

- absolute tightness. Such equipment is used for laying communications of a closed type, requiring protection against airing. Cold-deformed systems provide maximum protection against oxygen and gases;

- extensive assortment. The modern market of sanitary equipment can offer a huge number of varieties of pipes that differ in the method of manufacture, length, diameter, purpose and technical characteristics;

- strength. Metal is a hard and dense material, it is not subject to expansion as a result of working with hot substances, that is, parts are resistant to damage of a mechanical, biological and chemical nature. In addition, standards No. 8734 75 and 8733 74 suggest some of their varieties capable of handling aggressive substances;

- ability to withstand temperature extremes and heavy loads.Having a high melting point and due to the dense structure of the material, such pipes, unless, of course, their parameters correspond to GOST 8734 78 and 75, also function normally in cold weather. Due to the fact that these products are seamless, they better withstand the workload and pressure increase, as they have no weak points - joints.

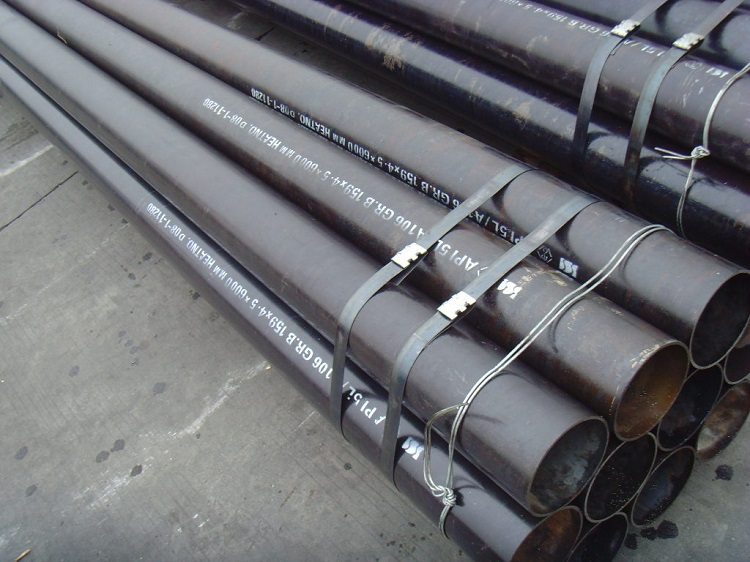

The parameters of the pipes are indicated on their external side, this allows you to determine their purpose and compliance with the conditions of the future highway

Helpful advice! Whatever variety you are interested in, make sure that the product meets the GOST standards (8734 75 for cold-deformed and 87 for hot-deformed). Distinguish high-quality steel seamless cold-deformed pipes produced according to GOST 8734 75 (as well as 78, 78, 87) can be in appearance and marking.

Cons of seamless pipes

Despite the large number of advantages, still the pipe has some disadvantages. Of course, they must be taken into account when choosing equipment. So, the disadvantages of steel pipes regulated by guests No. 8734 74, 75, 78, 81, 87 include:

- susceptibility to corrosion. Such a part has only one area vulnerable in this regard - a welded joint. However, in our time enough ways have already been invented to eliminate such a minus. This is done using various protective coatings, powder coatings, as well as by adding special substances to the alloy, such as, for example, according to GOST standard under the number 8733 74;

- heavy weight. Such a minus implies certain difficulties in the transportation of equipment and its installation;

- high price. When compared with analogues from other materials, metal equipment manufactured in compliance with all requirements of GOST 8734 75 and 78 is quite expensive. This is due, first of all, to the manufacturing costs, because such pipes have a high cost price;

- restriction on the length of the delivered segments. GOST regulates the length of pipes produced;

- high thermal conductivity of products. When installed in residential premises, this can lead to the destruction of the decorative wall decoration, as well as the danger of burns on the hot surface of the pipe.

Since steel pipes are heavy, the costs of using machinery for loading and transportation are inevitable

Features of cold-deformed products

It is worth paying attention to several important points regarding the design of pipes in order to choose the right product for your pipeline.

Steel pipes produced according to the GOST document differ:

- high level of thermal conductivity. This is fraught with some unpleasant moments. For example, if you use the product to supply hot water in the house, it is better not to install the pipes tightly against the walls, since the external surface of the product may fog up. And this will lead to dampness on the walls and, as a result, the appearance of fungus or mold;

- good electrical conductivity. Therefore, a cold-deformed part is not used to protect and insulate an electric cable;

- susceptibility to liquid freezing. Try to establish communications from pipes GOST 8734 74, 75, 78 in conditions more or less close to normal temperatures. If the transported liquid freezes inside the pipe, there is a risk of damage to the surface of the product;

- limitation of segments. For 1 km of communications, with a pipe diameter (according to 8734 78 standard) of 110 mm, there will be approximately 83-85 joints, and, accordingly, weak points.

Production Material

Steel pipes owe many advantages and disadvantages, of course, to the material from which they are made. Steel is a type of metal alloy that is resistant to the development of corrosion processes, strength and long service life.

Possessing a dense structure, a pipe made in accordance with state standard No. 8733 74 is tight and not subject to mechanical damage. Difficulties may arise when it is necessary to transport chemically aggressive substances using such pipes. The action of some of them can have a detrimental effect on the operational and strength characteristics of the material.

The composition of pipes according to GOST No. 8733 74 includes high-quality carbon and alloy steel. This provides a certain level of resistance to the effects of biologically and chemically active substances, however, this feature is not absolute for any aggressive environments. It is better to consult a specialist before using pipes for supplying caustic liquids and gaseous media.

Production process

In order to better understand the types of equipment and its quality, it will not be superfluous to familiarize yourself with the process of its manufacture, since it is at this stage that all the necessary parameters and qualities of the product are provided for by GOST.

In the manufacture of pipes, according to 8734 81 standard, the seamless production method is used. First, a carbon steel alloy ingot is made (according to the conditions of standard No. 8733 74). Then inside it with the help of special equipment (rolling mill with rotating rolls working on the drive), the plastic deformation of the workpiece occurs. As a result of this procedure, an opening of the desired diameter is formed inside the ingot. At the same stage, the thickness of the walls of the workpiece is also regulated.

Finished pipes are checked for compliance with the parameters that are determined by accepted standards

The specificity of the pipe manufactured according to this GOST is that in its production a cold rolling method is used. This means that during the formation of the product, according to standard No. 8734 75, a lower temperature of the metal is maintained than that which is necessary for recrystallization. After the main part of the process is completed, the pipe is tested for compliance with all declared quality standards. The part is checked for strength, resistance to damage and for the presence of other parameters. Further, the products are packaged and prepared for sale.

Scope of application

Pipes made in accordance with GOST 8734 75, 87 (hot and cold formed) are a very popular product. Moreover, not only in the market of sanitary products, but also in various sectors of engineering, furniture industry. In addition, the use of steel seamless cold-deformed pipes GOST 8734 74 is also acceptable for decorating rooms. However, pipes, as an element of communication systems, are of course the most popular. It can be water pipes adapted for supplying cold and hot water. In addition, such a pipe is used to supply and transport fuel substances, as well as gaseous and liquid chemically active substances.

Helpful advice! It should be borne in mind that steel is susceptible to the effects of some particularly aggressive chemicals, therefore, when choosing a material for a communication system, pay attention to the properties of the working medium and compare the real parameters of the pipe material with the standards of GOST 8734 75 and 8733 74.

Steel pipes are made different in length, diameter and thickness. Therefore, this material is very convenient for the manufacture of various furniture elements (legs of tables and chairs, backs, etc.) and decor.

Pipe classification and parameters

Depending on some factors, there are various types and types of pipes. The shape of the section distinguish:

- cold-deformed steel seamless pipes GOST 8734 75 and hot-deformed GOST 8734 87 of annular cross-section;

- profile (flat oval, rectangular, oval).

Cold-deformed and hot-deformed pipes are classified as seamless pipes, the production of which is regulated by GOST 8734 81 and 87 (the latter for hot-deformed ones). A distinctive feature is the absence of a seam. This gives them some advantage in strength, in the percentage ratio of 5-10%. There are also welded steel products produced according to standard 8734 74. They are straight-seam (the seam is located along the entire length of the pipe) and spiral-seam (when the pipe is sewn in a spiral).

By appointment:

- special. They include, for example, profile ones. Such pipes are used to replace reinforcing structures and load-bearing elements during construction and repair;

- general purpose. This is a standard seamless pipe with an annular cross-section, used for water supply, gas transmission and heating systems. Its quality is regulated by standard No. 8734 75 - for cold-deformed and 87 - for hot-deformed.

According to the ratio of diameter and wall thickness:

- especially thin-walled. The diameter of such pipes, according to the norms of standard 8734 78, is 20 mm, and the wall thickness is 0.5 mm. The ratio of these parameters for such pipes is more than 40;

- thin-walled with the same diameter, but with thicker walls — their thickness is from 0.5 to 20 mm;

- thick-walled, according to the 78th standard, characterized by a diameter of 6 to 250 mm, wall thickness 1.6 - 24 mm;

- especially thick-walled.

The range of seamless steel pipes includes products with a wide variety of diameters and wall thicknesses.

Specifications

To select the right equipment needed for specific purposes, you need to study its technical parameters. In this case, all parameters correspond to their standard number:

- GOST No. 8734 78 determines the outer diameter, length and wall thickness of the products;

- GOST 8734 75 is responsible for the quality of products entering the market;

- GOST 8734 74 - regulates the production part, that is, determines the standards for metal rolling;

- GOST 9941 81 relates to pipes for hot and cold rolled stainless steel, regulating production standards;

- GOST 8734 87 defines the quality of hot-rolled metal.

Such an important quality as the chemical composition, on which the scope of the product directly depends, is regulated by standard No. 8733 74.

Equipment and apparatus

If you are confident in your abilities and decide to make the pipeline yourself, then be prepared to get special equipment.

Helpful advice! If the volume of work is small, then it will be much more profitable to rent equipment, since in case of acquisition the costs will not pay off. However, if there is a lot of work, then on the contrary - it is more profitable to buy a device than to pay for its rental.

So you will need pipe bender. This is a device adapted for bending and deformation. Such a technique will become a necessity, especially if the room in which the system is mounted is with inaccessible corners or curved walls.

In addition, you will need tools for cutting pipes, as well as chamfering machines, threading machines and accessories (screw clamps), devices for rolling grooves. Select such equipment in accordance with the parameters of wall thickness, diameter and length of pipes specified in the norms of standard No. 8734 75, 78, 87.

The connection of steel pipes, especially large diameters, requires the use of welding and welding skills

Installation algorithm

Before you begin, plan your system.

Break the pipeline into sections and install, if necessary, supports and suspensions. This item applies to large communication complexes. When assembling an oversized device from seamless cold-deformed steel pipes (GOST 8734 87), it is not necessary to mount the supports.

Now you can start assembling the individual parts. Knots and blocks are welded using a special apparatus.

After that, we stack, assemble and connect all the parts using the same welding.Make sure that the joints are correct and even - these are the weakest points of your system.

Then you need to hold a series of final events.

- Install, if necessary, automatic control devices, fittings, compensators, as well as drainage devices.

- Verify the correctness of the work done by testing ready-made communications, driving water through them.

Steel pipes are a popular material used in various fields of construction. Both professionals and amateurs work equally well with him. In any case, it is important to choose high-quality products and carry out installation in accordance with all the rules, the only way to achieve failure-free operation of the pipeline.