Electric-welded steel pipe is a popular part of water supply systems. It has been known since the twentieth century. Maintaining the necessary performance over time, it has an affordable price, while being reliable and durable. However, when choosing equipment, you need to pay attention to shortcomings and installation rules, and only then determine whether it suits you. Therefore, it is better to familiarize yourself with the main features of this product even at the planning stage of the system.

Electric-welded pipes - one of the most popular types of materials for the installation of pipelines for various purposes

Content

Main characteristics

Electric-welded straight-line steel pipes were used and are being used for arranging communications of various types by design and purpose. These are heating systems, and hot and cold water supply, as well as gas supply, ventilation structures, elements of towers, towers, and even as decoration elements. They are used in mechanical engineering, and in metallurgy, and in many other industries. Electric-welded steel pipes popular in construction even as part of reinforcing cages.

Despite the fact that in the plumbing market they began to gradually lose their position in favor of newer and, from some points of view, more advanced plastic parts, there is still quite good demand for longitudinally welded steel pipes for pipes. This is explained by the fact that not in all cases it is better to save, and not always light weight and ease of installation are decisive factors.

Important! Of the polymers, only pipelines are constructed to supply the coolant, and the heating devices themselves - for example, a register or radiator, are made only of metal.

Steel equipment has many advantages when compared to plastic equipment, however, in some ways it is inferior to it. In any case, it is better to study all the nuances of both steel electric-welded pipes and various polymer pipes before deciding which type to use for your own purposes.

Main advantages

This type of equipment has many very significant advantages. Among them:

- strength. Metal is a reliable material. It is much more resistant to mechanical damage than, for example, polyvinyl chloride or other types of polymers. It is harder and harder. Such pipes can also be laid by the open method, without fear that they will be damaged;

- large assortment. Steel pipes are used in almost all sectors of the economy. This is construction, and repair, and engineering, and the mining industry, and the gas transportation industry, and many others. Electric-welded profile pipes (galvanized, stainless steel or ferrous metal), for example, are popular as a substitute for reinforcing structures in the construction of buildings of various types;

- universality. The range of such equipment is applicable in buildings of all types and purposes, and, as mentioned above, they are used in various sectors of the economy and industry;

- attractive price.Such pipes have a very reasonable price, commensurate with the quality, while having remarkable technical characteristics. Of course, plastic analogues are somewhat cheaper, but in some cases, such savings are not justified and result in even greater costs of time and money. And in some (albeit rare) cases, even tragic consequences;

- galvanized steel pipe electrowelded has a low coefficient of linear expansion. This is a huge advantage over polymer analogues, since in their case it can cause accidents, leakage of hot water and, as a result, damage to property and even harm to the health and life of people in the room;

- they are not afraid of ultraviolet. Steel pipes are a product that is resistant to sunlight. This is partly why registers and other similar devices are built from it, because such material allows installation by an open method. This will not affect its strength properties, service life and performance characteristics in any way.

Due to the fact that the steel is insensitive to ultraviolet, pipes made of this material are used when laying land highways

Cons of the product

Despite the high technical indicators, steel plumbing equipment has certain disadvantages. It is in some aspects substantially inferior to polymer.

For example, if we consider gas pipeline communications, the transportation of plastic equipment during their arrangement is much more convenient (since technical pipes are transported in bays) and costs less. This is due to the compactness and light weight of PVC.

Among the minuses of the products presented in the range of steel electric-welded pipes, there are also such factors:

- They are subject to corrosion. The main problem of metal is rust. In this, polymers, of course, benefit. However, nowadays pipes are made of stainless steel or with protective spraying. In addition, a galvanized pipe is popular in the market.

- They have a lot of weight. To transport and install heavy metal pipes is not as convenient as polymer pipes. In addition, they do not have the same flexibility as PVC products, so they cannot be installed in the most inaccessible places..

- Electric-welded longitudinal steel pipes, due to their technical characteristics, are more difficult and longer to install. The melting temperature of the metal is much higher than that of PVC, for example, and to bend it you need more effort, skills and knowledge, as well as equipment of a certain power. Yes, and cut the desired length is much more problematic - here you can not do with a knife.

One of the drawbacks of steel pipes is their weight: to work with large diameters, you need to attract special equipment

Features of steel pipe

To ensure a calm heating season, you need to choose the right communications equipment. Of steel pipes, a special heating device is often made - a register. It is a welded metal pipe, which provides greater productivity and heating area. It is also quite acceptable for him to use aluminum and cast iron. To supply the coolant, steel pipes are used along with copper, iron, and brass.

The market can offer a rich assortment of products of any shape, type, and purpose. From profiled massive elements to decorative tubes. When choosing, it is important to consider the level of load and the complexity of the tasks assigned to the pipeline.

There are two types of equipment: seamless and welded. The assortment of steel welded straight-line pipes includes products made using a welding machine. It has some disadvantages compared to a single-rolled analog. The presence of a seam suggests a large load on this section of the product, which means there is a threat that under pressure and the influence of high temperatures it can diverge.

However, if the power of the heating register does not go beyond the limits of the norm - that is, it is not so great, then steel welded pipes. For example, for a private home or office building, they are quite suitable.

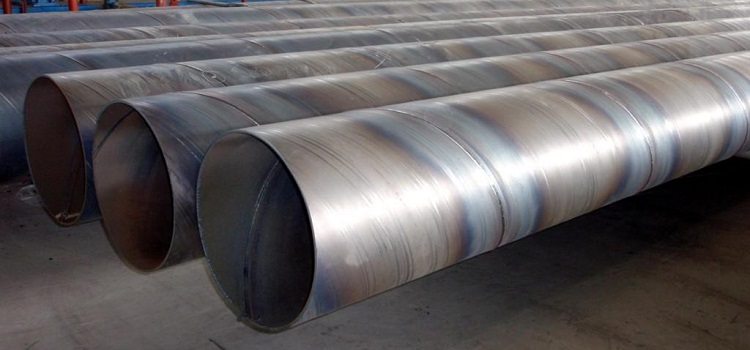

Electric-welded pipes have a connecting seam (straight or spiral), which can turn out to be a weak point at high loads on the pipeline

When buying, also pay attention to the diameter and wall thickness so that the equipment lasts a long time and there are no accidents due to congestion of the system.

Production process

Nowadays, there is a huge assortment of metal plumbing. At the same time, goods differ both in price and in quality, as well as in operational parameters. So that when choosing it is better to understand the quality of the product, it will not be superfluous to get acquainted with the process of its production. After all, it is at this stage that all technical characteristics, level of strength and product life are determined. So, a steel pipe is manufactured in the following steps:

- harvesting. The steel sheet is cut into pieces of the desired area. This is the future pipe;

- after it is sent to the forming compartment with rolls and welded. If the seam goes along the product in a straight line, this type is called straight-seam, if the sheet is wound in a spiral, then such a product is included in the assortment as spiral-stitched;

- then there is reinforcement of the seam, strength testing and verification of compliance with all necessary GOSTs. Nowadays, there are technologies due to which such a weld strength is ensured that it is only 10-15% lower than the strength of other pipe sections, that is, such products are not much inferior to seamless products in terms of resistance to stress.

Helpful advice! Pay attention to the integrity of the seam and the thickness of the walls when buying. Try to purchase parts from large metal rolling outlets and only at well-known construction outlets. Remember that technical specifications and product quality are a guarantee of the safety of property in your home and the health of your loved ones.

To make a pipe, the sheet of metal is folded along or twisted in a spiral, and the joints are welded with an electrical unit

Register for heating

A special heater - register - an excellent solution for a private house. This is a system, which, as mentioned above, is a welded metal pipe vertically connected by jumpers. This design is not new, its principle is used in the design of most radiators and many heating systems.

Registers are of three types depending on the material from which they are made:

- Aluminum. They are characterized by durability, because they have all the advantages of metal and are not amenable to its main disadvantage - corrosion. In addition, the register gives off heat well and has a low specific gravity, and is also very durable. It is often installed in residential and commercial buildings. The main disadvantage of the equipment is the high price. According to this criterion, such a, albeit qualitative, register is significantly different from analogues from other materials.

- Cast iron. The register from this material will be heavier, therefore more often they are installed permanently. However, they are easier to install, because the parts are connected by a flange method. In addition, since this metal is less ductile and cannot be influenced by high temperatures of the heated fluid, it does not deform and is more resistant to mechanical damage. The minus of cast iron is a tendency to corrosion, but if you treat the metal with special substances, then this is not a problem for him.

- Steel. For such systems, electric-welded straight-seam steel pipes with chamfers are mainly used.

In addition, there are mobile and stationary devices.The fundamental difference between them is the power and area of action.

If the second type requires the purchase and installation of a boiler, from which it will be powered, the first is less demanding. For its operation, an electric heater is needed that works from a standard network of 220 V. But such a mobile register is not suitable for a large house. It is more suitable for gatekeepers or temporary premises for builders.

In addition to the advantages, equipment such as the register has certain disadvantages, the main of which is slow cooling. This is especially true for cast iron products. Such a minus is less pronounced in aluminum products, since this material gives off heat faster.

The scope of steel pipes with a weld is quite wide. This is due to their technical qualities. Such pipes have drawbacks, too, but they do not play a significant role in the installation of certain systems, since in such cases reliability and durability are important.