Home improvement is an issue that is relevant in any season, each owner seeks to do everything possible for comfort and warmth. In private house-building, metal pipes for heating remain a priority in regions with harsh climates. If the heating equipment is optimally selected according to the footage of the building, then communications are subject to minimal load. But sharp cooling is possible when the boiler is operating at maximum, in this case only pipes for heating from metal will not fail.

Various types of metal pipes - this is the most practical solution for the heating system in both the apartment and the private house

Content

Varieties of metal pipes for the heating system in the house

Self-assembly of the heating system from metal pipes causes certain difficulties. They are produced in a certain meter, which makes it difficult to turn around when working with DIY welding. The most difficult thing is to work in narrow rooms, where you have to additionally use turn signals or bend the pipe. But the service life of metal pipes for heating is sufficient in order not to think about replacing it for one generation.

Note! The heating equipment market offers boilers of various types, and the cross-section of metal pipes should correspond to the nozzle (outlet) of the boiler. Then the internal load on the heating system will be minimal, and the pipes will become less clogged on rotary fragments, and in radiators less sediment will precipitate during the entire service life.

A large selection of metal pipes allows you to use them in various national economic fields. These are water and gas pipelines, chimneys and heating systems, pipes for the installation of frame structures and furniture. For heating in the private sector are used:

- seamless rolled metal pipes;

- welded straight-seam and spiral-seam;

- Cold rolled and hot formed.

All these varieties, even welded pipes, are suitable for arranging the heating system of a country house with their own hands, since they are less susceptible to water hammer during the seasonal start of the system.

The welded pipe is checked by a flaw detector, which is able to detect the slightest deviations of both the inner and outer seam. Their cost is cheaper, but the guarantee of reliability and service life is similar to solid products.

It is interesting! Practice confirms that any product at the seam breaks last, even if it is perforation. So for longitudinal pipes you should not worry if they become the basis of your heating system.

Do-it-yourself installation of heating from metal pipes involves the choice of the thickness of the product of different sections. As you know, the thicker the pipe, the more expensive they are, and the greater their weight (mass). But is it always justified to opt for thick iron pipes, which inside rust just like thin ones? Seamless metal pipes of large thickness are recommended only for use in conditions of increased internal pressure, as well as for overloads from temperature extremes.

In addition, heavy pipes give an additional load on the foundation, which is extremely undesirable in a multi-storey building on floating soils.

Pipes for heating in a private house are offered in different types:

- standard (ordinary);

- thick (reinforced);

- thin-walled (lightweight).

Tip! Pipes for heating with a large wall thickness and high anti-corrosion performance are used in systems with maximum load, including open areas. They bend worse, require special welding and sufficient experience in repair work and DIY installation.

Electric steel is used to connect steel pipes, and it is better to entrust a specialist with such work when installing heating

For heating from metal pipes, you can use products of any shape:

- round;

- rectangular;

- oval.

Installation of a heating system with metal pipes made of copper and steel is recommended to be entrusted to a specialist.

Criteria for choosing metal pipes for heating

When building a house and installing a heating system with your own hands, the main question arises - which metal pipes are better? As you know, the metals used for communications are classified as:

- the black;

- color;

- alloys.

The first category includes rolled steel, galvanized iron and cast iron. Non-ferrous metals do not rust, but oxidize, these are:

- bronze;

- copper;

- aluminum and others

Attention! The service life of metal pipes for heating systems varies, and for a copper pipe it is maximum, but it is the most expensive. More often they use metal pipes for heating from cast iron and steel, stainless steel and aluminum.

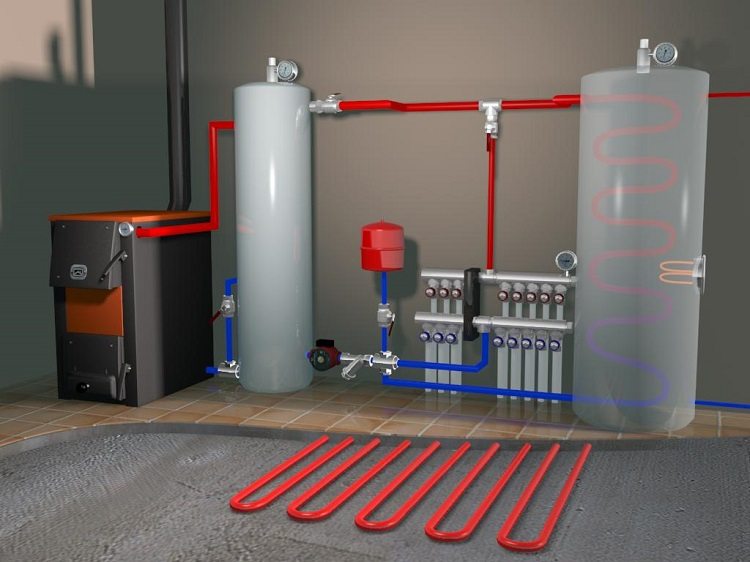

The type and layout of the heating system is one of the decisive factors when choosing pipes for the network

The main selection criteria:

- type of heating system (gravity or forced);

- maximum load (the conditions of the northern regions differ in the heating period of the southern latitudes);

- the ability to replace sections of the pipeline with the highest load;

- installation method (hidden or closed, inside the walls);

- general system configuration, including the number of storeys of a private house;

- design and maximum pressure inside;

- kind of coolant;

- do-it-yourself transportation and installation options;

- total length and budgetary framework for installation;

- maximum possible temperature in the system.

Performance requirements for metal piping for heating

It is necessary to consider the most important characteristics of steel pipes. It:

- mass of products;

- dimensions in accordance with GOST and individual order (TU);

- outer and inner diameter (cross section of the conditional passage of the coolant and wall thickness);

- metal properties.

All parameters for this product are reflected in the legend. The length of the pipe is measured in meters, the diameter of the cross-section and the walls of the pipe is in millimeters, the mass is in kilograms, the pressure is in Pascals, the temperature is according to Kelvin and Celsius. The parameters of pipe formation and type of welding are indicated by a capital letter. The service life, measured over the years - is rather arbitrary, depending on a number of factors mentioned earlier.

One of the advantages of metal pipes is the high pressure resistance that is present in any heating system.

The advantages of metal pipes and their cost

For classic do-it-yourself installation of a heating system for a one-story private house using a solid fuel or combined boiler, ordinary ferrous metal pipes are used. There is no need to take thick pipes of large diameter for heating with metal pipes in a gravity sample system. But whether they will rust over time is a more important selection criterion.

The main advantages of pipes for heating in a private house:

- strength;

- reliability;

- durability or long service life;

- the possibility of partial replacement of the damaged area;

- maximum thermal load;

- ability to withstand large internal pressure;

- tensile strength and external mechanical stress;

- the ability to weld a pipeline of any configuration;

- high thermal conductivity:

- reasonable prices;

- the possibility of self-assembly in the presence of a welding machine and relevant experience.

Consumers often refuse welded pipe in favor of seamless, but these costs are not justified under the standard load on the heating system of a private house. But it makes sense to pay extra for galvanizing the pipeline, since these products are better protected from destruction, they practically do not rust and almost do not clog.

Disadvantages:

- transportation costs;

- the difficulty of cutting pipes, their installation and dismantling;

- large length of products;

- low resistance to corrosion, rust and sediment;

- the need for external insulation and painting;

- during correction, welding damages the finishing materials.

Note! The "price-quality" ratio can also be attributed to the advantages of installing heating from metal pipes with your own hands in a private house. But communications from non-ferrous metals cost an order of magnitude more expensive, they also have more time-consuming installation.

Some sections of the pipeline are joined by couplings or fittings. And although this excludes welding, additional costs for these components are required when installing the system yourself.

Brief characteristics of each type of metal pipe for heating

1. Copper pipes.

There are two varieties - pipes that have undergone additional hardening and products made from boiled copper, which is more malleable in forging. They require a special silver soldering, which is available only to specialists. The most expensive and durable pipeline.

Copper pipes are the most durable and safe for humans products from all that are used for heating installation

2. Stainless carbon steel.

Such products are universal for the heating system with metal pipes in all respects - they have a long service life and excellent appearance. They are corrosion resistant and able to withstand maximum loads.

3. Galvanized steel pipes.

They have a small layer of zinc alloy coating to protect them from rust, but they break down over time. For threaded connections without welding, fittings with the same coating and properties are required. Self-welding of these pipes is harmful to health!

4. Pipes made of ferrous metal.

Among the shortcomings of products, consumers most of all blame for metal corrosion, shorter service life and the need for periodic flushing of the heating system. Both threaded joining with subsequent sealing, and autogenous welding are used.

5. Cast iron products.

A special alloy of iron and carbon, the heaviest and most stubborn. It does not rust, most often cast iron is used in the form of fittings and couplings, it is recommended for closed installation.

6. Pipes made of aluminum.

Products are rarely used for heating systems, but light metal is indispensable with a minimum load on the foundation.

Installation of heating is an important task, for the solution of which it is necessary to take into account a lot of factors. Installation is the final stage, and it can be carried out independently. But the choice of pipes is influenced by the results of various calculations, the implementation of which is best left to specialists. After all, not a single, even perfectly mounted system will not function without interruptions if the materials do not meet the loads in it.