Recently, pipes made of polymers are becoming more and more popular. They are used in almost all sectors of the home, farm and industrial sectors. Polypropylene communications are often used for heating installation, since they cope well with the transport of hot substances, they have numerous advantages. However, it is important to know all the qualities of such a product, its features and possible limitations on its use.

Polypropylene pipes are an affordable material that is not inferior in properties to metal products and is used in heating systems of varying complexity

Content

Characterization of polypropylene as a material

If we compare it with other types of plastics, then polypropylene is less dense than, for example, polyethylene, but it is more resistant to mechanical damage and abrasion. In addition, this material is able to withstand high temperatures, is water resistant and less prone to stress cracking (especially reinforced) than other types of polymers. This allows you to use it as a basis for heating systems.

As for its chemical properties, polypropylene is relatively resistant to the negative effects of various reagents. Destruction is possible only with prolonged exposure to high temperatures or in the case where halogens and nitric acid are the reactants. Organic solvents have a particular effect on polypropylene products. Under their action, even at room temperature, the material will begin to expand.

He is not afraid of high temperatures and steam. It melts when heated more than, for example, polyethylene.

Important! It should be taken into account that ultraviolet rays and oxygen have a strong effect on polypropylene parts: with their participation, the development of destructive processes faster, the mechanical characteristics noticeably deteriorate and the service life is reduced.

In addition, polypropylene is susceptible to extremely cold conditions. Pipes from it can function normally at a maximum of 5-10 degrees below zero. If the air temperature goes beyond these parameters, this negatively affects the operation of the pipeline and can lead to the future failure of the polypropylene pipe.

The advantages of polypropylene pipes

Almost everything is made from polypropylene - from films to parts of water supply lines. Their popularity is due to a large number of advantages.

Among them:

- flexibility. Such pipes can be laid even in the most inaccessible places, since the material itself is very plastic, and can take almost any shape. Therefore, they are often used when installing floor heating systems;

- strength. As mentioned above, the material itself is tough and resistant to mechanical damage. Accordingly, the polypropylene part has the same advantages. Such communications are not afraid of minor damage;

- durability.The pipe from this plastic is quite durable and with proper installation and operation will last you 50-70 years;

- low price. Compared to metal and copper counterparts, this product benefits greatly, as it has a lower cost. Not inferior to metal products in strength and durability, it is more affordable;

- universality. Polypropylene pipe is used in various industries. It can be used to heat the floor, insulate and protect the power cable, transport cold and hot water, and also as part of a heating system. The type and size of the building does not matter - such equipment works great everywhere;

- heat resistance. The polypropylene pipe functions quietly at 96 degrees heat, which makes it possible to work with hot substances;

- simple construction and simple installation. This plus allows you to speed up and facilitate the installation of the pipe, and also eliminates the need to resort to the services of specialists - such a system can be connected independently;

- a light weight. This greatly facilitates the handling of equipment and its transportation.

Installation of polypropylene pipes is carried out in a very simple way, therefore, all work on the device of the pipeline can be done independently

Types of polypropylene products

Before acquiring plastic communications, you should familiarize yourself with the main types of such products and choose the best option for yourself, based on their features.

So, a polypropylene pipe happens:

- PN It is less versatile and heat-resistant; it is used only for transporting cold water.

- PN This species can withstand high temperatures and it is precisely it that is popular as a part of hot water supply and heating systems.

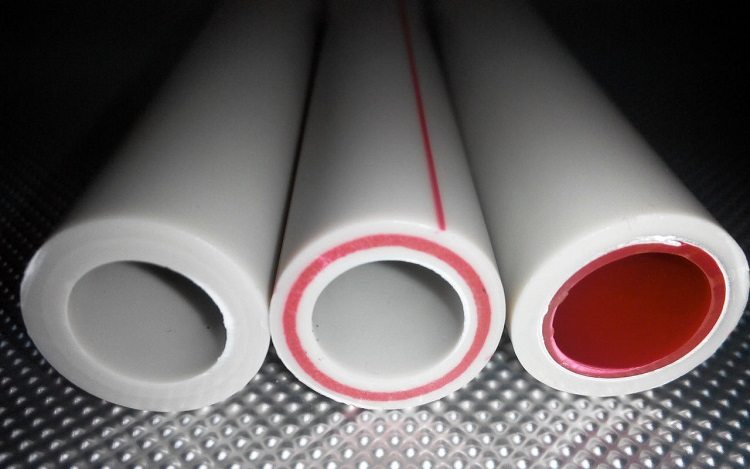

- Reinforced (aluminum or fiberglass).

If you just need to provide a supply of cold water, then it is better to limit yourself to the first view.

However, when using the second one, an important feature should be taken into account: polypropylene increases in size under the influence of high temperatures. This means that it is better to install it using an open method. Otherwise, these decorative ceilings may crack or even get significant damage. And under the influence of extreme temperatures, the pipe can crack or break at all. This is fraught with damage to flooring, interior decoration, possibly furniture and utensils. In addition, this can be dangerous for people in the room. For heating gaskets in a closed way (laying in concrete, cement) reinforced pipes are used.

For the heating system, pipes are needed that can work at high carrier temperatures, so you should choose products with a reinforcing layer

Therefore, the best option for polypropylene pipes for heating is reinforced. These pipes have a protective layer that keeps the product from excessive linear expansion during operation.

Types of reinforcement

There are only two types of material with which pipes are reinforced.

Aluminum. This is a more advanced type of reinforcement. Since polypropylene has such a significant drawback as expansion under the influence of high temperatures, which makes it an unsuitable material for heating, this variety has gained particular popularity - the layer of aluminum foil ensures the preservation of the shape of the product, preventing expansion, thinning and, as a result, damage to the pipe walls. This is important, because it can lead to material losses and a serious danger to the health and life of people in the room where the equipment is installed. There are two types of aluminum-reinforced products - when the metal layer is between the inner and outer shells of polypropylene, and when it is installed on the outside.

With all the advantages, even this protection has its drawbacks.There is a risk of acquiring low-quality reinforced goods, in the manufacture of which low-quality glue was used, which leads to delamination of the pipe and the loss of its operational characteristics. Such a product will quickly disable the heating system.

Fiberglass. Equipment reinforced in this way is not subject to delamination. The design of such a pipe is comparable in strength to a monolith. It consists of three layers: polypropylene inside and out, and between them is a mixture of it with fiberglass. All layers are securely soldered together and will not separate under any conditions. Such equipment has the lowest coefficient of linear expansion.

Polypropylene pipes for heating, reinforced with fiberglass, are installed only after preliminary processing of the cut. That is, you need strip polypropylene pipe a special tool, namely, remove the layer above the fiberglass before soldering the system parts.

Mounting Features

The process of installing polypropylene pipes reinforced with fiberglass for heating a house is extremely simple and quite feasible on our own. However, this does not mean that you do not need to know anything to implement it. It has its own characteristics and nuances:

- reinforced aluminum or fiberglass pipe is installed with fittings. There are many of them - more than 20 species. Read them carefully and use only suitable ones;

- make sure you have everything you need to install. The installation procedure for fiberglass-reinforced parts involves the use of special soldering machine. Be sure to set the desired temperature on it (270 degrees), take care not to overexpose the reinforced workpieces on the heating element. The standard time is 5 seconds. It may be necessary and more if the product has a large diameter or work is carried out in conditions with low air temperature;

- since polypropylene pipes reinforced with fiberglass for the heating system are connected by soldering, be careful and follow all necessary fire safety rules when working with equipment;

- correctly solder. Please note that there are two nozzles on the apparatus - for melting the inner and outer surfaces. It is necessary to warm up both. Then connect reinforced pp pipes. Never rotate the ends of the workpieces! This will cause deformation of the layer;

- then flanging. Make sure that the ends of the parts are connected evenly, fix them for about 30 seconds, so that the welding hardens and does not deform.

Helpful advice! Be careful not to overexpose the workpiece during heating. Otherwise, the interior of the product may become clogged. In addition, reinforced polypropylene for heating can ignite. This will become clear from the characteristic brown color.

As you can see, there is nothing complicated in this process. If you follow all the necessary rules, then for laying heating from polypropylene aluminum-reinforced pipes, you will not need to attract professionals and spend extra money, and the system itself will last for decades without breakdowns.