When installing hot water pipelines or heating systems, the question often arises of finding an alternative to expensive pipes made of copper and other types of metal. Polypropylene products are best suited as their counterpart. But conventional polypropylene structures have a lot of disadvantages. Therefore, modern manufacturers began to produce another type of PP pipes - products with fiberglass reinforcement.

Content

Advantages and disadvantages of polypropylene pipes

One-piece polypropylene pipes for which the PPR mark is accepted on the market outperform plastic and metal products in many ways. They are inexpensive, durable and lightweight. Transportation of products from this type of plastic to the place of work can be done on their own. Installation Such systems do not require special skills and professional equipment. Polypropylene tolerates low temperatures well: its structure does not break even after freezing and thawing water in the pipeline.

Along with this, products made of solid polypropylene have characteristics that do not affect their performance in the best way. First of all, this is a fairly low melting point. Polypropylene begins to melt in the factory at 175 degrees. This plastic can become soft already at 130-140 degrees.

It would seem that with a stable temperature in the heating system equal to 90-95 degrees, this limitation can not be taken into account. But do not forget that when combining factors of high pressure and high temperature in the system, the influence of hot water affects much more noticeably the resistance of the material. Therefore, the loss of integrity of polypropylene in sections of the pipeline with pressure drops is quite likely.

Reinforced pipes in comparison with ordinary pipes are more durable and resistant to temperature changes.

Also, polypropylene tends to expand markedly when exposed to heat. Usually a long deformation occurs: pipes stretch, waves appear on their surface. This phenomenon is undesirable not only for aesthetic reasons. In cases where polypropylene pipes are recessed under the screed or laid in the wall covering, a change in the physical size of the structure will entail cracking of cement and plaster.

Polypropylene pipes reinforced with fiberglass or aluminum can, if not completely deprive plastic products of all the shortcomings, then at least an order to improve their performance. The reinforced layer makes it possible to safely use pipes in any heating and water supply systems.

Which polypropylene pipes are better: reinforced with fiberglass or aluminum?

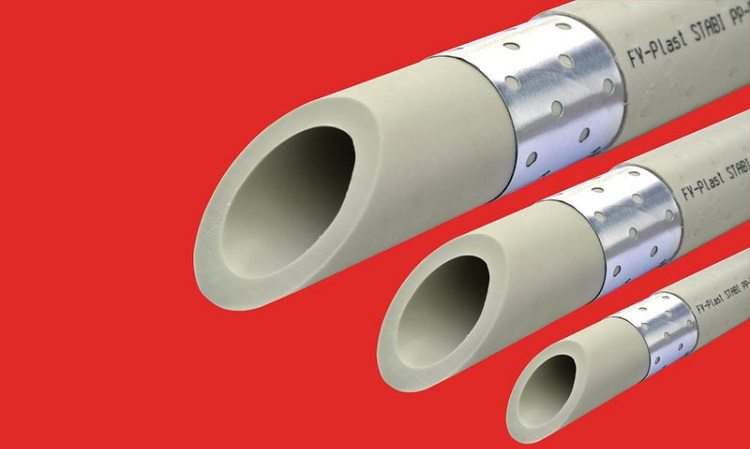

To increase the strength of polypropylene pipes, two types of reinforcement are used: using aluminum foil and fiberglass.The aluminum sheet may be perforated, may cover the product from the outside, or may be located in the middle of the pipe between two layers of polypropylene. A layer of fiberglass is always placed inside a polypropylene pipe.

If the pressure in the future pipeline is high, it is better to use pipes equipped with a layer of aluminum

Helpful advice! Aluminum reinforcement increases the ability of the pipe to withstand high internal pressure. If it is not known exactly what characteristics the pressure in the mounted system will have, it is better to purchase pipes with an aluminum frame.

Products with aluminum reinforcement (marking PPR-AL-PPR) have high rigidity, withstand loads and are not subject to deformation. The aluminum layer is from 0.1 to 0.5 mm, depending on the diameter of the structure. Aluminum foil is bonded to the base material with glue. If a poor-quality adhesive was used in the production, the pipes may delaminate. The reinforced aluminum propylene pipes, made technologically correct, do not lose their tightness over time.

The presence of aluminum reinforcement involves additional installation operations. Before soldering, the aluminum layer must be cleaned. Without stripping, the pipeline will cease to function quite quickly. Firstly, this will happen due to the delamination of the foil and plastic during melting; secondly, due to the destruction of aluminum due to electrochemical processes in the system.

A feature of polypropylene pipes with fiberglass is that the reinforcing layer in this case is very similar in composition and properties to the main material. During welding with a fitting, polypropylene and fiberglass form a strong alloy, not subject to delamination. Therefore, pipes made of polypropylene reinforced with fiberglass can be called a more versatile, simple and, most importantly, durable option.

Characteristics of fiberglass reinforced polypropylene pipes

Fiberglass is a more modern type of reinforcement than aluminum foil. Pipes reinforced with such a material have a three-layer construction.

The fiberglass reinforcing layer is located in the middle of the pipes - between the layers of polypropylene

Moreover, the inner layer, which performs the function of reinforcement, is the same polypropylene, but with the addition of fiber fibers - fiberglass. The adhesion characteristics of fiberglass to plastic are almost equal to the monolith. Fiberglass reinforced polypropylene pipes are marked as follows: PPR-FB-PPR.

This variety of reinforced pipes has many positive properties:

- lack of likelihood of corrosion in the system;

- the walls of polypropylene pipes are very smooth, which prevents the occurrence of deposits;

- products have high strength indicators, do not deform under the influence of heat;

- well tolerate chemical and biochemical effects;

- characterized by low hydraulic resistance, so the pressure loss in the system will be negligible;

- have soundproof qualities;

- do not change the composition of water, do not emit substances harmful to humans.

Fiberglass, in fact, plays the role of a frame that does not allow polypropylene to expand under certain conditions. Fiber fibers do not affect the performance of the piping system, but only improve its performance. The approximate operational life of fiberglass polypropylene pipes is more than 50 years.

Helpful advice! The characteristics of polypropylene pipes reinforced with fiberglass are inferior to pipes with an aluminum frame, perhaps in only one case. The stiffness of fiberglass products is much lower, therefore, for systems with a length of more than 1.5 m, it is necessary to use special fasteners for the walls.Otherwise, the pipeline will deform due to sagging.

Reinforced pipes need to be fixed with special clips or clamps, placing them strictly over a certain distance

Fiberglass reinforced pipes of various diameters are available. When choosing the required size, the purpose of the pipeline must be taken into account. Models with a diameter of less than 17 mm are used for laying warm floors, 20 mm - for home hot water systems. Diameter from 20-25 mm is used for the installation of heating equipment in public places, as well as for the installation of sewer risers. Depends on the diameter and pipe mounting method: for small plastic clips are suitable, for large it is better to use clamps.

Installation methods for polypropylene pipes with fiberglass

The installation of pipes with fiberglass reinforcement does not differ from the connection of whole polypropylene products. There are three methods for mounting reinforced structures:

- using threaded fittings;

- cold welding (glued couplings);

- diffuse welding.

Connection by threaded fittings is carried out by means of a circular crimping of the mounting nut. The pipe is put on the fitting fitting and is pressed with force. The connection comes out very tight, and it is almost impossible to spoil the parts in the workflow. This method can be applied even in pressure pipe systems. The only difficulties that may arise are the force of pressing the fitting. The nut may burst due to too much pressure.

Cold welding, in which the connection is carried out using a special adhesive, does not provide sufficient reliability to the joint. In this case, polypropylene couplings are used, on the inside of which glue is applied. Then a piece of pipe is inserted into the coupling and the structure is held in one position for a while so that the glue seizes.

The diffuse welding method is not inferior in strength to a threaded joint. The disadvantage of this technology is that it requires an additional tool - a welding machine. Temperature for soldering calculated depending on the diameter of the pipe and the thickness of its wall.

Fiberglass reinforced polypropylene pipes today are ideal for home heating and plumbing systems. Inexpensive and high-quality, they are devoid of significant shortcomings, and therefore perfectly solve the problems of products made of solid polypropylene and successfully replace the usual metal structures.