The installation of heating equipment on any type of fuel (gas, solid fuel boiler, fireplace or stove) involves the design of a system of pipes that exhaust combustion products. In the last century, there was no alternative to brick, and then asbestos-cement chimneys. Such systems had a significant number of shortcomings, so now they are almost completely squeezed out of the market chimney pipesmade of stainless steel.

Stainless steel chimney is a reliable and durable design that can be installed with different types of boilers

Content

Characteristics of stainless steel chimneys

Stainless steel pipes are not the only products manufactured for heating boilers. Chimneys are aluminum, ceramic, and enameled steel. But it was stainless steel that gained maximum popularity. The reason for this was a wide range of advantages that this material has:

- universality. Steel pipes can work with most types of equipment running on any fuel and energy source. Smoke hoses made of stainless steel used even in industrial systems;

- ease of maintenance. Preventive cleaning of chimneys made of steel can be carried out at any time of the year, without waiting for a complete shutdown and cooling of the system;

- availability repair. If one of the elements of the chimney fails, there is no need to change the entire sleeve. It is enough to simply replace the failed element;

- fire safety. On the smooth walls of the steel tubing, toxic soot and gas remain in much smaller quantities than on more porous and rough asbestos-cement or ceramic. With a complete tightness of the system, the risk of burnout of the chimney will be minimal.

Of course, stainless steel chimneys also have disadvantages. These include thermal conductivity, which provokes the occurrence of condensate on the walls of the system. Over time, this problem can lead to a complete failure of the smoke channel.

Helpful advice! Breakage can be avoided if pipe insulation is performed in a timely manner. If there is no way to make insulation with your own hands, you should purchase a ready-made construction of the type of "sandwich.

Principle of procedure pipe insulation will depend on the characteristics of a particular region. In the northern latitudes, the insulating structure may consist of several layers.

What are stainless steels for chimneys?

Steel itself, as you know, is not the best material for the manufacture of pipes. Especially designed for such a serious operation as removing smoke from the heating system. Plain (or black) steel - the material is durable, but highly susceptible to corrosion.

The problem of rust on steel products was resolved when stainless steel was used in production. The resistance of this material to corrosion is due to the fact that chromium was added to the alloy of ordinary steel.When interacting with oxygen on a surface containing chromium, a special film is formed with an anticorrosive property.

There is a classification of stainless steel used in the creation of various products:

- Steel of class AISI 430 (as well as AISI 409, AISI 410) will have a mass chromium content of 11%. For the production of pipelines, this class is not suitable, since its use is possible only in slightly aggressive environments. The use of steels of such classes is advisable in the manufacture of dishes and interior elements.

- Steel grades AISI 304 or AISI 321 have a chromium content of about 17%. Also, the alloy will include nickel, which provides ductility to steel. The alloy is widely used in pipe production. Such products are not only not covered with a layer of rust over time, but can also function perfectly at temperatures up to 450 degrees. The use of chimneys from the presented steel classes is possible only under temperature conditions not exceeding this limit.

- Steel of class AISI 309. This variety is considered heat-resistant material, the alloy contains at least 25% chromium, and nickel - at least 20%. Chimneys made of such an alloy can be operated in higher temperature conditions, as well as in systems of fireplaces, solid fuel boilers and gas turbine units.

- AISI 316 steel. In addition to chromium, titanium and molybdenum are also part of stainless steel. Chimneys made of this class of material are optimal for use in all conditions. The maximum temperature for the AISI 316 class is 800 degrees, which fully meets the requirements of modern heating systems.

- AISI 310S grade steel. The most expensive and heat resistant material. It is distinguished from other species not only by its absolute resistance to chemical (acid) effects, but also by its ability to withstand temperatures as high as 1000 degrees.

The entire range of steels differ in quality, purpose and, accordingly, cost. Manufacturers primarily offer class 304 stainless steel chimneys that are affordable to most consumers in terms of price and performance.

The main requirement for smoke exhaust hoses is the thickness of their walls. This is especially true for gas-fired boilers. The thickness of the chimneys for such equipment should be more than 1 mm.

Stainless Steel Chimney Design Options

Chimneys can be sold with different equipment and delivery. There will be three variations in total:

1. Chimneys from a single layer of material. The simplest mono-constructions made by the factory method from stainless steel sheet with a thickness of 0.6 mm to 2.0 mm. Normal operation is possible only indoors, the use of mono-systems without insulation in the open air dramatically reduces the performance of not only the channel itself, but also the heating device.

Helpful advice! A single-layer chimney can be a low-cost solution for secondary heat sources: water tanks, outdoor heat exchangers in areas.

2. Corrugated stainless steel construction. They can be used as an independent chimney duct or as an auxiliary element for a smooth steel system. Corrugations significantly save the budget when designing chimneys with a large number of curved transitions. However, illiterate installed corrugation may lead to depressurization of the sleeve and fire. Inspectors from the gas services do not recommend the use of corrugated steel, especially if the channel is mounted by a lay person.

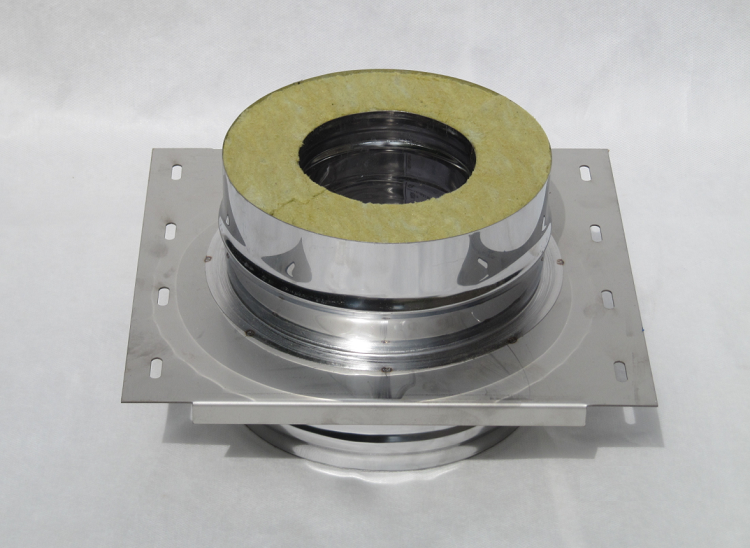

3. Sandwich pipes. They are considered the easiest to install and use. Buying elements of this type at the same time solves the issue of thermal insulation of the system. Sandwich chimneys, in fact, consist of two pipes of different diameters.A smaller-diameter product is placed in a larger pipe, and the distance between them is filled with heat-resistant material (usually basalt mineral wool). Chimneys from this discharge can be indoors or out.

What parts are needed for a stainless steel chimney pipe?

The choice of accessories for the chimney will depend on the initial drawing. You can choose everything you need from the existing range:

- Direct sections of chimneys. The length of straight sections, which are the basic part of any smoke channel, can vary from 330 mm to 500 mm and 1000 mm. Direct sections of the system are fastened with a simple bell method, they do not need any connecting elements.

- Knee (discharge) with an angle of 45 degrees. Designed to change the angle of inclination of a straight pipe. The scope of the outlet knees is vertical and inclined (horizontal) sections.

- Bends from angles of 90 degrees. Universal part: due to the fact that the design of the outlet elbow with a right angle consists of four elements, the angle of inclination can be changed from 0 to 90 degrees. They are used mainly when connecting a short horizontal part extending from the boiler (pipe) with the main smoke hose.

- Tees. Various configurations are available: 87 and 45 degrees. They play an important role in the maintenance of the chimney. Using tees, it is possible to clean the system and fix the main channel with a condensate collector. They are also used as splitters when connecting two sources of heating (the procedure requires the agreement of the relevant authorities).

- Revision Also, like tees, facilitate the cleaning of the chimney from internal contaminants. It is usually installed under the base of a vertically directed chimney channel under the tee.

- Condensate collectors. Needed to release excess moisture from a vertical smoke barrel. Watering cans are also installed under the tee.

- Protective elements for the top. As protection against atmospheric precipitation, fungus deflectors, weathercocks, waterproofing skirts are used. Spark suppressors also protect fireproof roofs from fire.

- Other details. Also, during installation, heat-resistant penetrations through the roof, penetrations for walls and floors are used.

Installation of modular channels and chimney sandwich - quite an unproblematic event. It is possible to achieve effective operation of the system even without having the baggage of special knowledge in this area. Choosing a chimney and accessories from a suitable steel grade and compliance with technical standards will make it possible to install a safe and airtight system.