All owners of private houses know about the need to remove combustion products that appear during the operation of a heating boiler, fireplace or stove. To do this, they create a chimney in their home through which toxic substances move due to draft. Modern manufacturers produce many options for such products. But the chimney pipe sandwich is especially popular today.

Content

Design features

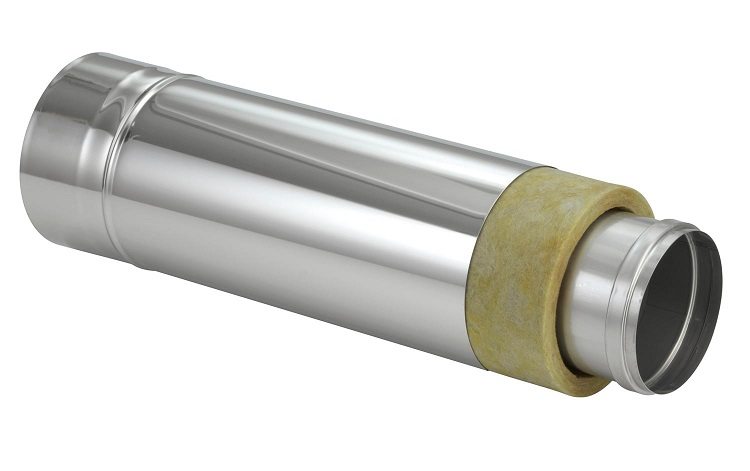

In accordance with their name, they consist of two pipes: internal and external. The inner pipe is made of stainless steel. In addition to the stainless steel, other materials can be used for the manufacture of the outer pipe. For example, the use of less expensive galvanized steel is allowed. Of course, the reliability of the chimney sandwich pipe made from it will be less. The corrosion process at the site of damage to the zinc coating will begin immediately.

Between the pipes there is a layer of thermal insulation. As a result, the design of the chimney sandwich pipes contributes to the effective removal of combustion products from the furnace due to the fact that:

- the outer contour of the chimney pipe sandwich is reliably protected from overheating by a layer of thermal insulation. This technical solution prevents the formation of condensate on the surface of the outer pipe.

- the internal circuit perfectly withstands heating to high temperatures;

- in the chimney provides rarefaction of gases at a sufficiently high level and the necessary draft;

- The design of the chimney sandwich prevents moisture from entering the insulation layer.

Even if the boiler does not work for some time, in severe frost, due to thermal insulation, the pipe will not become icy and will not freeze. After the furnace turns on, the draft will appear instantly, which eliminates the poisoning of the inhabitants of the house with carbon monoxide.

Today, the production of many types of sandwich chimneys designed to work in different temperature ranges has been established. They differ in diameter, as well as the thickness of the insulating layer. The type of their connection can be bayonet, “cold bridge” and flanged. When choosing it, it is necessary to take into account the individual characteristics of the heating unit.

Modern industry also produces a special type of stainless steel chimney sandwich, as the raw material for the manufacture of which heat-resistant steel is used. Its installation is usually carried out if necessary in the removal of gases from solid fuel furnaces and boilers of high power.

Pros and Cons of Chimney Sandwich

Like all types chimney pipes, these products have their own advantages and disadvantages. They are due to the use of certain materials, installation method and other points.

First, we will talk about the cons. There are not many of them. Here it is worth highlighting:

- rather high cost of the main structural elements;

- short service life. While ordinary brick chimneys have been operating for several decades, sandwich pipes are able to fulfill the functions assigned to them for about 10 ˗ 15 years;

- gradual decrease in the tightness of the chimney.The reason is the constant narrowing-expansion of the sections caused by temperature changes.

Pros are much more significant. So, for example, when installing a sandwich pipe for chimneys with your own hands, the contractor does not require professional skills. It is enough to follow the rules, which will be discussed below.

In addition, this type of chimney is attractive due to:

- universality of design. Conclusions can go not only upstairs, but also through walls;

- compact pipes;

- multi-layered prevents a large amount of soot from settling in the chimney;

- the sandwich pipe is not exposed to aggressive environments, high temperatures and chemically active products that appear during operation;

- this version of the chimney is the most fireproof of all existing;

When performing installation, the construction system does not constitute a significant obstacle and therefore it is not necessary to use the services of specialists.

Good to know! It is recommended to install a chimney pipe a sandwich indoors, and to bring its outlet to the roof. The efficiency of removing through the wall is much lower, so this method is rarely used. However, this option has the right to life.

How to choose

When installing a chimney from a sandwich pipe with your own hands, this issue deserves special attention. The main criterion for choosing these products is the grade of steel from which they are made. It must be indicated in their technical passport.

Below are the most commonly used steels and their features in terms of creating a do-it-yourself sandwich chimney.

AISI 430 Steel. It is a chrome-iron low-carbon stainless steel. Its main features are as follows:

- tolerates exposure to mild corrosive environments;

- It resists the oxidation process at high temperatures;

- steel becomes brittle at temperatures approaching zero;

- weldability is mediocre. It is not allowed to produce welded products from it under load.

From a technical point of view, the installation of such a sandwich pipe for chimneys of fireplaces, stoves and solid fuel boilers of low power is justified.

AISI 304 Steel. This product is an austenitic stainless steel containing nickel and titanium. Basic properties:

- excellent stability in mild corrosive environments;

- maintaining high strength at low temperatures;

- good weldability.

Installation of chimneys AISI 304 stainless steel sandwich is recommended for the removal of flue gases with temperatures up to 300 ° C. This is a great solution for geysers and boilers.

AISI 316 Steel. The main difference between this brand and the previous one is the presence of molybdenum, which increases the corrosion resistance of the structure. The installation of a chimney sandwich made of AISI 316 steel will be justified if the heating unit runs on gas, diesel fuel or wood and is characterized by high power.

AISI 310 steel. Heat resistance is the main advantage of this brand. Sandwich pipes made from it withstand heat up to 1000 ° C. It is preferable to install a chimney made of sandwich pipes made of such steel when coal stoves and boilers are used for heating, as well as units on wood, peat briquettes and others.

AISI 32 steel1. The limit of heat resistance of this brand of steel is less and amounts to 600 ... 800 ° C, but it is characterized by increased resistance to corrosion. It is recommended to install a sandwich made of it chimneys for wood-burning stoves.

Helpful information! Owners of private houses who decide to install a chimney from a pipe sandwich with their own hands, ask if it is possible to determine the grade of steel? If there is no marking on the structures, then this, in general, cannot be done. But there is one sign that makes it possible to determine good stainless steel, that is, in which alloying additives are present in large quantities - magnets are not kept on it. Conventional steels are characterized by pronounced magnetic properties.

Despite the fact that steel is present in the design of the chimney made of sandwich pipes, it is not necessary to build a foundation for it.

An equally important characteristic is the thickness of the insulation. Recommendations for choosing a sandwich pipe taking into account this parameter, depending on the unit used, are presented in the table below.

| Type of heating aggregate |

Insulation layer thickness, mm | Temperature of exhaust gases, ˚С |

| Wood stoves and fireplaces | 50…100 | 300…600 |

| Solid fuel boilers | 50…100 | 400..700 |

| Gas turbine units | 50 | 450..600 |

| Diesel generator sets | 50 | 450…500 |

| Gas piston units | 50 | 450…500 |

| Microturbine plants | 50 | 300 |

| Diesel boilers | 250 | 150…200 |

| Gas boilers | 25 | 110…180 |

| Condensing gas boilers | 25 | 60 |

DIY installation rules for a chimney from a sandwich pipe

The procedure for assembling a chimney of this type through the roof involves the following actions:

- preparation of the required technological holes in the ceiling and roof. This should be done on the basis that the removal of unprotected structures from the pipe should be at least 380 mm;

- then a start module (sandwich mesh) is installed, which increases the life of the chimney and its efficiency. According to the installation conditions, its installation directly on the heating unit is not allowed;

- DIY assembly It starts like this: the inner pipes are condensed, the outer pipes are smoke. The inner part is inserted into the lower pipe. Install the outer part to the outer pipe of the lower module. In this case, all joints must be carefully treated with prepared silicone sealant;

- passing through the ceiling part, it is necessary to use asbestos paper, having previously cut a hole in it, the diameter of which is equal to the value of this parameter of the pipes. Cover the installation box with crushed clay, foamglass or other loose insulation at your disposal;

- To complete the installation of a chimney sandwich through the roof with your own hands, you will need a master flash unit. Outside the pipes are fastened with self-tapping screws and clamps.

To prevent debris and sediment from entering the chimney, a protective visor is installed on the top of the chimney. The larger pipe segment should be indoors. This technical solution helps to minimize the level of heat loss.

When installing the chimney through the roof with your own hands, be sure to follow the assembly instructions provided by the manufacturer.

Important! Sandwich chimney equipment should include a draft level control system. It can be realized by mounting the gate inside the main pipe.

Do-it-yourself sandwich pipe installation for a chimney through a wall

The initial stages of this work do not differ from the installation of a system for removing toxic combustion products through the roof. However, in the future it must be carried out taking into account some nuances. The first of them sounds like this: when installing a chimney from a sandwich pipe through a wall, a channel can be laid in it only in a place where there are no communications.

- it is better to plaster the places of passage of the chimney through the wall, having previously filled the space with thermal insulation material, and not just close it with a protective casing.

- the gap between the chimney mounts is 60 millimeters.

- Doing a pipe through a wall with your own hands involves changing its direction. This is done using a tee with a cleaning cup. It is fixed by a bracket.

- in the place of construction output through the overhang of the roof, joining pipe segments to each other is not allowed.

Subject to all the necessary requirements and rules, arranging a chimney sandwich through the wall with your own hands is reliable and simple. But we must not forget that the pipes require care. In particular, in order to prevent smoke blocking, they must be regularly cleaned of foreign objects.