PND corrugation is a product which is made of low-pressure polyethylene and is used in various situations. With the help of a corrugated pipe, drainage systems are laid from this material, and it also serves to protect cable wiring, acting as a cable case. Today there are several varieties HDPE corrugated pipes, all of them possess high operational characteristics.

Content

Scope of use of PND corrugated pipe

HDPE corrugated pipes can be mounted both inside and outside buildings, as well as in a closed way (underground) or in an open, above-ground way. Today, in the construction market, you can find a wide selection of HDPE corrugated pipes of any required sizes and diameters, which allows us to expand the operational sphere of these products.

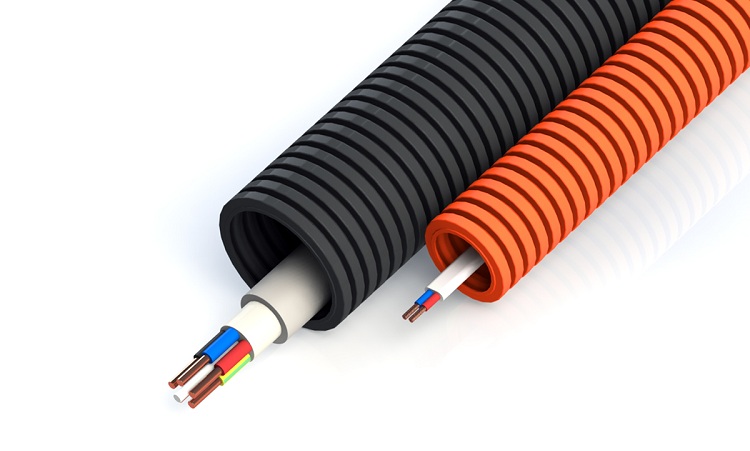

In order to protect the wiring from environmental influences (temperature, precipitation), as well as from mechanical damage, smooth rigid pipes made of polymeric material can be used, however, the use of corrugation HDPE for these purposes is considered a more reliable option.

A flexible HDPE corrugated pipe is a channel that has a circular cross-sectional shape and a ribbed structure. Ribbed outer surface gives the channel the necessary indicators of rigidity. And the inner wall of such a corrugated pipe is smooth, due to which it is easier to pull the cable, which does not meet any resistance in its path.

Flexible HDPE corrugated pipe is mounted on walls, ceilings or on the floor. It is important to note that the laying of products from this material should be carried out on non-combustible or slightly combustible surfaces.

Note! In order to simplify the process of pulling the cable through the corrugated pipe, it is usually equipped with a special probe. The probe is an ordinary wire that is made of steel. In some cases, a nylon cord is used instead of steel wire.

As a rule, such flexible corrugated tubes are laid in niches of building structures. If a corrugated pipe made of this material is installed in difficult conditions - it is laid in special concrete channels (shtrobs). Such products are used to protect power cables and any other wiring, combining excellent flexibility and high rigidity. In addition, they are used to equip drainage systems.

Let us consider in more detail the operational branches of these products:

- monolithic type construction;

- telecommunications;

- power supply;

- drainage systems;

- transport infrastructure.

Advantages of HDPE pipes

Like any other product, a corrugated pipe made of low-pressure polyethylene has its advantages, which are worth paying attention to:

- such products are quite resistant to temperature extremes. The temperature range of HDPE corrugated pipes varies from −25 to +90 ° C. This property allows you to mount communications from these products at almost any time of the year.Installation in severe conditions does not affect the technical characteristics of the corrugated pipes;

- HDPE ribbed parts, among other things, are characterized by high strength characteristics. This is due to the presence of stiffening ribs. Due to this property, they are allowed to be installed underground, laid in concrete or organized communications on the surface;

- if we are talking about laying inside such parts of cable wiring, then this measure is simplified thanks to the presence of special wiring. Such a wire makes it easy to pull the cable through the corrugated pipe;

- it should be noted that the flexibility of such products allows the implementation of protective channels for cable wiring without the use of special connecting elements - fittings;

- HDPE corrugated products are another useful property - they can stretch or, conversely, taper. Changing the length as necessary is a very convenient quality;

- corrugated pipes made of this material are resistant to the harmful effects of corrosion;

- such pipes are resistant to aggressive chemical compounds, therefore they are allowed to be laid in soils;

- the smooth inner wall of such parts does not create resistance when moving wastewater through them in drainage systems;

- they are easy to install;

- the operational life of these products during normal operation can reach 40-50 years (and in some cases more).

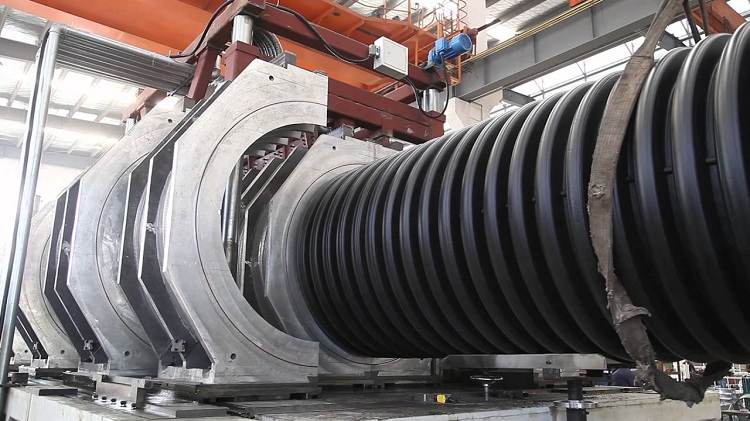

Heavy pipes are used for underground installation and for the installation of highways operating in difficult conditions

However, such products have some disadvantages:

- such corrugated tubes have low resistance to ultraviolet rays. Under the action of ultraviolet radiation, they lose their properties, which leads to their destruction;

- PND products are not a budget option, unlike other polymeric materials.

Important! Such pipes are strictly not recommended as a channel for transporting hot water.

Types of corrugated pipes HDPE

Today, there are several main varieties of these products. They differ in their design and purpose. Consider a variety of corrugated plastic pipes from HDPE.

PND corrugated hose (single-layer lightweight corrugated pipe). This version of the HDPE pipe is quite simple to perform, and also easy to install. A single-layer HDPE corrugated hose is capable of changing its length or bending angle, and also does not need additional fasteners. There are two types of hoses that differ in their purpose:

- hose used for cable management (equipped with wire);

- a hose that does not have additional structural elements and is used to transport various liquids.

Weighted PND corrugated hose. Such products are distinguished by high cross-sectional indicators and are used in difficult operating conditions (they are mounted in a cement screed or laid in a closed way in the soil).

Double-walled PND corrugation. Consists of two layers:

- external ribbed;

- inner smooth.

This design allows these pipes to be durable and ductile. Such products are distinguished by excellent throughput due to the smooth inner wall. Such products may be:

- conventional (made entirely of HDPE);

- combined. The inner layer of such products is made from HDPE, and the outer one from high pressure polyethylene (LDPE).

Double-walled reinforced PND pipe. It is produced, as a rule, from two layers of HDPE, between which there is a metal layer. This design allows you to tolerate high mechanical loads, impacts and has a high coefficient of ring stiffness.

Characteristics of HDPE corrugated pipe

Corrugated pipes made of this material are quite durable products, however, there are certain limitations that are prescribed in the regulatory documentation governing their laying. To lay such products in the ground is allowed to a depth of not more than 3 m.

The long service life of these products allows you not to worry about their frequent replacement, however, do not forget that communications from HDPE pipes can fail due to mechanical stress or other unforeseen situations. The diameter of such pipes can be very different. As a rule, pipes with cross-sectional indicators from 110 to 1000 mm are used. Characteristics of corrugated HDPE pipes depending on the cross-sectional index (DN) are presented in table No. 1.

Table 1

| Mm | Internal index of section, mm | External indicator of section, mm | Weight 1 p m, kg |

| 1000 | 851 | 1000 | 40,5 |

| 800 | 678 | 800 | 24,5 |

| 500 | 427 | 500 | 12 |

| 250 | 216 | 250 | 3 |

| 200 | 176 | 200 | 1,8 |

| 160 | 139 | 160 | 1,5 |

| 110 | 93 | 110 | 0,9 |

Helpful information! PND corrugations are stored and transported in special coils (bays). The length of the corrugation in the coil can vary from 15 to 100 m.

As a rule, the standard color of this material is black. Black corrugation is the most common and is characterized by the highest strength characteristics. Black corrugated pipe is a reliable and effective device that is used in most cases for underground installation. In addition to black PND corrugation, there are other colors: yellow, white, orange, etc. The color of the corrugation determines its quality characteristics, for example, orange products are fireproof, unlike blue ones.

Installation of corrugated pipes from HDPE can be performed by any person who does not have special building knowledge and skills. The laying is also facilitated by the fact that such products can be joined together in various ways: using fittings, using welding equipment, and using special glue. Due to this, as well as the unique technical characteristics of the corrugations, from them you can perform the design of almost any configuration.

Corrugated HDPE pipe for drainage systems

To date, these products have gained great popularity in the arrangement of drainage systems of varying complexity. For the arrangement of drainage structures, as a rule, single-wall corrugated pipes from HDPE are used, which allows to reduce the total cost of work.

The low cost of simple, single-layer HDPE products is the main advantage that determines their huge popularity in the arrangement of drainage structures. As mentioned above, such products are manufactured and sold in bays having different lengths.

Installation of single-layer corrugated PND pipes is carried out by joining individual sections of communication with special connecting elements - sewer couplings. For the arrangement of drainage systems, there is another kind of such pipes - perforated. Such a pipe is equipped with holes through which water is discharged.

In the event that a corrugated HDPE pipe is purchased to equip pressure-free (gravity drainage), it is recommended that special attention be paid to such a parameter as the roughness coefficient. There is a certain pattern - the lower the roughness coefficient, the lower the resistance exerted on the liquid flowing down the pipe. Pipes for which this coefficient is small allow you to mount pressureless sewers at a small angle of inclination, which simplifies installation as a whole.