High-pressure hoses are flexible pipelines that are inserted into each other with rubber (plastic) tubes with connecting fittings. Such products are particularly durable due to metal winding or braiding. Through the WFD - high pressure armored hoses - the force is transmitted in machine mechanisms, hydraulic and motor fluids, water and oil emulsions are transported.

High pressure hoses are hoses that are manufactured using special technology and have high strength characteristics

High pressure hoses

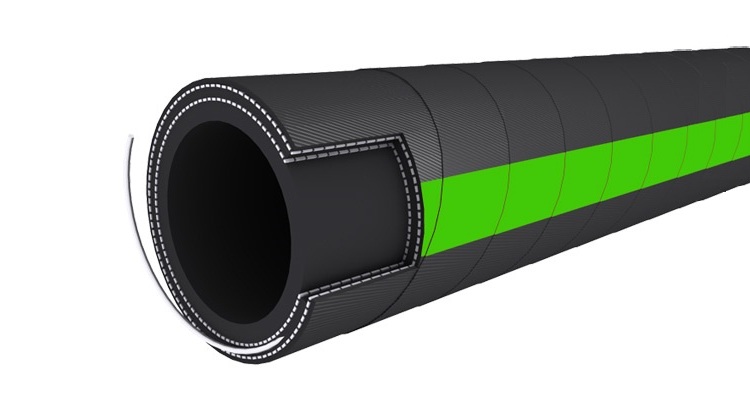

The specificity of the device of the high-pressure hose is determined by its purpose, operating conditions, during which it is exposed to aggressive environments and significant pressure. For this reason, oil-resistant rubber or synthetic rubber is used to make the inner layer. For the upper, thickened, wear-resistant rubber, sometimes complemented by a heat-resistant coating of corrugation, metal or plastic. Between the rubber layers - laying in several layers of metal wire (or textile), laid with thin rubber films. According to the method of winding, a high pressure sleeve can be:

- coiled. Regulated by the European standard EN 856;

- braiding, when winding is carried out at an angle and the crossing of the turns leads to hardening of the hose. The most common type, regulated by European standards EN 853 and EN 857.

The quality of the product is characterized by the following indicators:

- working pressure;

- temperature range of operation;

- bending radius;

- the cover (top layer) of the hose.

An essential element of the product are fittings for attaching high-pressure hoses. Possible application:

- nuts

- couplings;

- nipple;

- fitting;

- quick coupler.

Equipment for the production of

Equipment for the release of the RVD allows to produce:

- metal sleeve;

- stainless steel high pressure sleeve;

- rubber;

- braided;

- polytetrafluoroethylene;

- thermoplastic sleeves of high and medium pressure. Thermoplastics is becoming more common.

The main equipment includes such devices:

- marking machine;

- peeling machine;

- cutting machine;

- crimping press.

Additional equipment is also used, such as:

- reels for winding / unwinding hoses;

- devices for changing cams;

- beds for the press.

Good to know! For the production of products sent to metallurgical enterprises and construction organizations, multifunctional devices are required. Hoses for domestic use are manufactured on conventional machines.

The manufacturing process, commonly understood as crimping high-pressure hoses, is composed of the following steps:

- preparatory, during which the hoses are measured and cut;

- crimping, for which the use of transverse or longitudinal methods.

- tests designed to confirm product quality.

A metal hose and a thermoplastic hose are used in countless systems that use hydraulic or pneumatic drives, from aviation to utilities and household appliances.

How to replace and repair the hoses

The use of crimping equipment gives the hoses high reliability. The weakest point, as a rule, is the connection where fittings are used, which:

- are affected by corrosion;

- are leaking;

- lose tightness;

- break off the hose.

The failure of the fitting, which connects the hose to the equipment, in many cases leads to the need to replace the entire product

Among other damages that can be repaired, the most common are:

- hose breaks;

- abrasion of the upper layer;

- thermal damage to the internal.

Damage is caused by the following reasons:

- factory marriage. Handicraft or non-debugged equipment low-quality crimps the junction of the fitting and the hose;

- non-compliance with operating conditions, leading to the breakdown of fittings or rupture of the sleeve;

- the work of the main mechanism, when hoses that are sagging due to improper selection along the length of the hoses are cut and torn;

- non-compliance with the temperature regime when the outer layer of the WFD is destroyed.

Repair of the WFD, which consists in replacing the damaged area or fitting, is carried out in the following sequence:

- after disconnecting the damaged hose, a new one of a similar size is cut on the cutting machine, guided when replacing the marking data.

Note! The measuring points are the ends of the nipples.

- when working with the so-called heavy sleeve, designed for ultrahigh pressure, it will require the use of a debarker for internal and external cleaning of the ends of the hose, reaching the metal winding / braid;

- selection of fittings due to differences in standards that manufacturers are guided by may require the use of a caliper, thread gauge and special tables;

- having made a selection of fittings of the required diameter, they perform crimping using a crimping machine. Quality control is carried out using a test probe or bench testing.

With proper use of the WFD and timely replacement and repair of damaged areas and components, reliability and proper duration are guaranteed.