The apparatus for welding plastic pipes has become a popular tool with the spread of polymer structures. A variety of polymer pipes assortment gave rise to various welding equipment for arranging joints when laying the pipeline. The quality of installation and subsequent operation of the equipped system largely depends on the correct choice of a device for welding plastic pipes.

Content

- 1 The principle of butt welding and the device for it

- 2 Features of socket welding and assembly design

- 3 How to choose a machine for welding plastic pipes

- 4 How to choose a manual device

- 5 Socket Welding Machine Maintenance

- 6 Performing socket electrofusion welding

- 7 The choice of apparatus for mechanical (or hydraulic) welding of PVC pipes

The principle of butt welding and the device for it

The welding of plastic elements can be reduced to three types:

- Butt.

- Muftovom.

- Electrofusion coupling.

Butt welding of polymers, PVC, for example, is used in the case of uniformity and equal diameters. The ends of the parts are carefully adjusted to ensure the initial rigor of alignment and fit. Simultaneous heating of the ends of the connected structural elements achieves the required penetration depth of the melt, covering the entire cross section. Subsequent compression of the mating parts, when the force is directed along the axis, ensures alignment. The diffusion effect, when interpenetration of polymeric materials occurs at the melt site, ensures a solid joint.

Note! Fully polymerization is completed in the course of the subsequent technological pause.

An apparatus for butt welding of pipes is absolutely necessary when three conditions are required to achieve the quality of the connection:

- ideal machining of the ends;

- strict alignment;

- the most accurate calculation of the docking force.

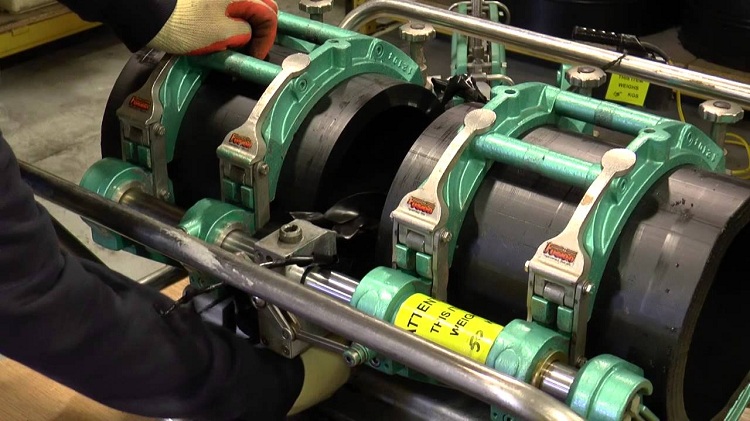

The apparatus for butt welding of pipes has a rather complicated design, since a high-quality joint requires a high accuracy of joining

Good to know! Such professional equipment is used even when laying trunk pipelines.

The butt welding machine for plastic pipes is a mechanism located on the bed. The bed is equipped with guides. Blocks moving along them provide fixed pipe alignment due to clamps and clamps. Clamp clamps, as usual, are provided with a set of liner segments for working with pipes of different diameters.

Electromechanical trimming machine in the form of a double-sided circular knife, removable or folding, the ends are processed. At the end of the stripping, the crosscutter is replaced by a flat round heating element, also removable or reclining at the hinge joint.

Having removed the heating element to the side, a compression phase is carried out due to the approach of moving blocks. The force is transmitted by mechanical transmission or hydraulic. Such a device is produced either universal or designed to work with pipes of a certain diameter.

Features of socket welding and assembly design

Socket welding can be used almost everywhere.The accuracy of joining PVC pipes as structural elements is determined by the correct selection of sizes of couplings to them. The sleeve is selected with a slightly smaller inner diameter compared to the outer diameter of the pipe.

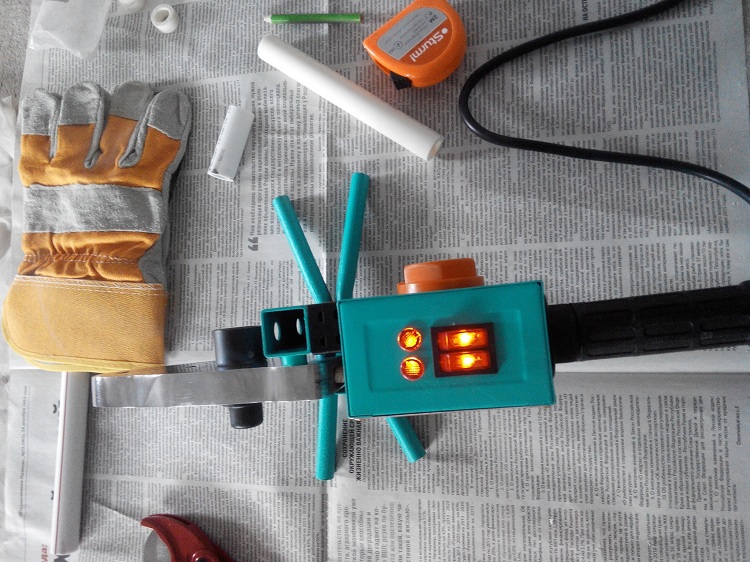

The manual apparatus has small dimensions and is most often used in everyday life for welding pipes of small diameters

At the same time, approximately equal length sections are heated. With muscular effort, the pipe is inserted into the coupling to the depth of heating. In principle, a socket connection is also made that does not require the use of a sleeve when one pipe is introduced into the provided socket of another.

A device for coupling plastic welding is simple. It connects to the network. The presence of the handle allows you to work, holding the device on weight, climbing into uncomfortable places. The required temperature is provided by the built-in thermostat-controller. The heating indicator on some models is with a digital indication. The main working part is a heater with electric spirals located inside for quick resistive heating of the surface. In through holes on the surface of the heater, heating elements are fixed in pairs:

- the sleeve warms up the outer surface of the pipe;

- mandrel - the inner surface of the fitting.

It is planned to install two or three pairs so as not to stop during operation, switching to work with pipes of a different diameter. Almost all devices come with a removable stand to install it on the floor or on a workbench. Equipment for welding large-diameter pipes is equipped with a heating element of a special shape and increased power.

How to choose a machine for welding plastic pipes

Choosing equipment for welding PVC and other polymeric materials, several factors are taken into account at once.

The type of apparatus for welding depends on which pipes they will weld and for what purpose the pipeline is being built

The nature of the work. This is what determines the type of soldering iron. Professional craftsmen, as a rule, stock up on devices of different types. Mobile and efficient hand-held models are successfully used by craftsmen who constantly fulfill orders for the assembly of polymer pipelines with diameters up to 50 mm. A mechanical apparatus is used when laying trunk pipelines when the volume of work performed is large.

Cost. It makes no sense to buy a professional model to connect two pipes in the household a couple of times a year.

The power of the device. For work with products with a diameter of up to 75 mm, less than a kilowatt is enough power, for large-sized ones - more than one and a half kilowatts. The principle of selecting the apparatus of the required power is extremely primitive - for soldering a ten-millimeter diameter, more than one tenth of a kilowatt of unit power is needed.

Complete set of equipment. The soldering iron comes as part of a standard set, a set of nozzles provides the ability to process pipes of different diameters. Extended equipment means a significant increase in cost. In the vast majority of cases, it is completely redundant. For use in servicing household communications, a set of four nozzles of basic diameters is quite enough. But it’s worth paying attention to the material of the nozzles. The most durable are made of Teflon or metal Teflon.

Manufacturer of equipment and country of production. For those who rarely use the unit, models with a low cost of Chinese production are quite suitable. Although, it should be noted, many Chinese manufacturers produce devices that do not differ much in quality from where more expensive European ones. Models of Turkish production occupy, as it is believed, a certain intermediate position. The model of a well-known brand, as a rule, is universal and is suitable for a professional master performing diverse work.

Manual devices come in various shapes and types, cylindrical models, as a rule. used by professional plumbers

For work with household communications, manual devices using a fairly simple design are used. The manual apparatus for plastic pipes varies in appearance, which is determined by the design of the heating element. Based on this parameter, it is customary to talk about hand tools of two types:

1. The xiphoid. The device is made, like its main part - the heating element, in the form of a sword. The nozzles are fixed on the bushings, the heating level is regulated by a thermostat, and the current temperature indicators are displayed. It is generally accepted that the xiphoid instruments are highly stable, which is very convenient in the process. Unfortunately, this important property is inherent, as a rule, to models produced by well-known manufacturers. When using additional nozzles, the instability of inexpensive tools increases sharply, even cases of upheavals are not excluded.

Good to know! The xiphoid type also includes equipment with a shortened heater, in which two nozzles are located vertically. This design provides a certain advantage when working in conditions of insufficient free space.

2. The cylindrical. This type of tool is used, as a rule, by professionals. Attaching nozzles to an elongated cylinder:

- direct;

- sideways. This model is L-shaped, which is extremely facilitated by use in hard-to-reach areas.

How to choose a manual device

When deciding to purchase a handheld device for work on household communications, they pay attention, first of all, to the fact that they will not need to weld pipes with a diameter of more than 50 mm. How to choose, if there are a lot of models of this type, they are quite functional and do not differ in high cost? Remind yourself once again that it is undesirable to weld even relatively dimensional pipes with a manual apparatus. The nozzles supplied to the market for work with large-sized parts, in terms of parameters, correspond in some way to them. Therefore, by connecting dimensional nozzles to compact equipment, you need to be prepared for difficulties with heating.

It is important to review the configuration of the proposed tool. In the case of a decent tool should be provided, in addition to a set of nozzles, the presence of useful devices for household work:

- wrenches;

- scissors;

- screwdrivers;

- roulettes;

- special gloves;

- level and other little things.

It is good if emergency shutdown is provided in case of a risk of overheating. It is desirable to hold the device in your hands, feel the weight and check the balance. The stand should be reliable and comfortable, especially if you have to work in the workshop. There are models, the stand of which is equipped with a clamp fixing the device on the working surface.

Socket Welding Machine Maintenance

When preparing the apparatus for socket welding for work, pay attention to the use of nozzles:

- check their cleanliness and dryness, because the presence of impurities will affect the quality of welding and will accompany the process with an unpleasant odor from their combustion. The use of contaminated nozzles is undesirable. They should be cleaned with a cloth moistened with alcohol or replaced.;

- establish nozzles, achieving uniform heating, without pushing beyond the edge of the heating element;

- nozzles for pipes with a diameter of 40 mm or more are installed in the rear holes.

After turning on the unit, they are allowed to warm up from ten minutes to half an hour. This range is due to the temperature of the external environment and the power of the tool used.After a break in operation, when the device was turned off, the heating procedure is repeated. While heating is in progress, the condition of the fixing screws to the nozzle is checked. Tighten the screws and install the nozzles should be a special tool in order to avoid damage to the coating nozzles. From time to time it is advisable to check the temperature of the instrument with a pin indicator or a special device.

When the device warms up to operating temperature, it is customary to start the first welding by waiting about five minutes. After completing work, the device is disconnected from the network and allowed to cool.

Performing socket electrofusion welding

When connecting to the socket, they work with special couplings that are placed between the joined elements and heated from the inside. This method, when the pipe is placed in the coupling, is the most reliable of all welding methods.

Manual disk-shaped devices are used when connecting pipes with a diameter of up to 125 mm, although they achieve the best results with three times smaller diameter values. The fact is that a manual connection requires speed of action, and with dimensional products it is not easy to achieve it, the quality of welding can suffer.

When working with dimensional pipes, they resort to the use of electrofusion welding machines, the design of which allows accurate alignment to be achieved when fixing the joined elements. Such high-tech equipment performs welding in an automatic mode, eliminating the marriage generated by the influence of the human factor. During the welding process, the operating parameters are displayed.

Note! Such equipment is used exclusively for large-scale work with large diameter pipes.

The choice of apparatus for mechanical (or hydraulic) welding of PVC pipes

A tool for welding polymer pipes can be equipped with a drive for supplying pressure:

- mechanical;

- hydraulic.

Pressure readings are monitored by a built-in dynamometer. The supply of pressure allows to achieve reliable fixation of the joined elements, which positively affects the quality of welding and the resulting connection.

Mechanical devices are used, working with low pressure, when welding pipes of small and medium diameters. An electro-hydraulic drive provides pressure up to 120 atm, which allows connecting products of medium and large diameters.

Choosing such a professional tool, pay attention not only to the cost. The possibilities of using are important:

- semi-automatic operation mode;

- work in an inclined position;

- electro-hydraulic drive;

- electrical trimmer.

Sophisticated equipment will not be compact and light, you have to put up with it. The choice is great, and a large company, and a master working with household structures, and an amateur can choose for themselves suitable equipment for welding plastic pipes.