All types of metal rolling have such an indicator as specific gravity. The weight of 1 running m of a steel electric-welded pipe can be calculated in different ways: by special design formulas or according to tables. To determine this indicator, you need to familiarize yourself with some of the provisions.

The weight of a steel electric-welded pipe depends on many factors that are necessarily taken into account in the calculations

Content

Classification of Steel Electric Welded Pipes

Electric-welded steel pipe is represented by two types that differ in cross-sectional shape:

- round;

- square.

In addition, all steel electric-welded products can be divided according to their purpose into:

- gas and water pipes with large cross-sectional indicators;

- electric-welded products that are used in laying trunk communications.

Trunk electrowelded parts, in turn, are of two types:

- straight-seam;

- with a spiral seam.

Longitudinal pipes appeared at the beginning of the 20th century and are still actively used in the construction of pipelines to this day. Electric-welded products are used in many industries, but the most popular are gas and water supply, as well as the laying of trunk pipelines. In addition, the following operational areas of such products can be distinguished:

- furniture manufacturing;

- construction industry (installation of frame structures);

- household needs (fences and other structures).

According to their quality characteristics, there are 4 main groups of electric-welded products: A, B, C and D. Pipes, which belong to category A, are distinguished by the fact that during their production control is carried out only on the mechanical composition. Category B includes products with a normalized chemical composition, and category C - parts that are produced with standardization of the mechanical and chemical composition. Products belonging to category D are subjected to hydraulic tests.

Important! There may be slight deviations in thickness along the entire length of the metal. As a rule, such deviations do not exceed 15%.

It is also worth noting that all these products are divided into 2 classes according to accuracy:

- I - are available with machined ends and removed burrs from the ends;

- II - pipe ends are not processed.

The length of electric welded parts varies from 4 to 12.6 m. One important point should be noted here: the mass of the pipe depends not only on its length, but also on the wall thickness.

Specific gravity. What is it and how to determine this indicator?

Specific gravity is an indicator that indicates the mass of one linear meter of pipe. Such a value is very convenient, since it allows you to very quickly determine the total mass of a part or a whole batch of pipes.

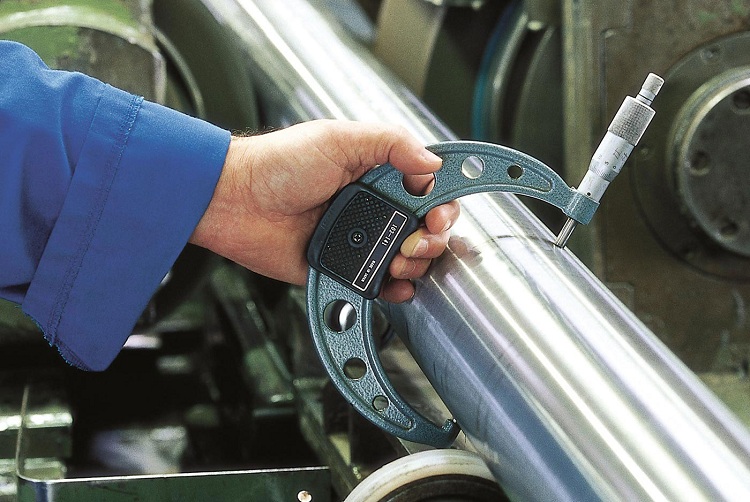

For calculations you need the following information:

- an indicator of the outer section of the pipes;

- wall thickness;

- length;

- steel grade (for a more accurate calculation).

All these data can be found in the relevant documentation that comes with the pipes, and you can also take measurements yourself. Each size has its own specific gravity. This value is derived through certain calculations, after which, multiplication by the length of the pipe is performed and the total mass of the product is obtained.

Table 1

| Type of electric-welded pipe (DN / wall thickness) | Theoretical specific gravity, kg |

| 630x10 | 152,9 |

| 426x10 | 102,6 |

| 89x5 | 10,36 |

| 159x6 | 22,64 |

| 530x7 | 90,29 |

| 57x3 | 4,0 |

| 114x3.5 | 9,54 |

| 325x10 | 77,68 |

| 102x4 | 9,67 |

| 630x8 | 122,7 |

| 159x4 | 15,29 |

| 377x6 | 54,9 |

| 377x7 | 63,87 |

| 325x6 | 47,2 |

| 127x4 | 12,13 |

| 426x9 | 92,56 |

| 219x8 | 41,63 |

| 159x5 | 18,99 |

| 426x6 | 82,46 |

| 76x4 | 7,1 |

| 273x8 | 52,28 |

| 114x5 | 13,44 |

| 325x5 | 39,46 |

| 108x4 | 10,26 |

| 426x7 | 72,3 |

| 89x3.5 | 7,38 |

The total mass of rolled metal is a very important characteristic that allows you to determine such moments as:

- the amount of raw materials that must be spent on the production of the party;

- accounting and transportation.

When transporting pipes, it is necessary to know their weight, as well as the weight of the products appears in all accompanying documentation (accounting, warehouse, etc.). Therefore, determining the weight of 1 meter of an electric welded pipe is a necessary measure.

The total weight of metal is necessary in order to determine how the transportation of products will be carried out. In addition, this indicator is needed when buying and selling pipe metal.

Methods for determining the specific gravity of steel electric-welded pipes

The weight of electric-welded pipes, as well as any others, depends on the mass of 1 m and geometric data, which include: section indicators, length and thickness of products.

The length of the product for calculating the specific gravity is 1 m. For steel electric-welded pipes, there is a constant indicator that sets the density of the product. This indicator is always equal to 7850 kg / m3.

In order to calculate the specific gravity, you must perform the following steps:

- You can see the weight of 1 m of steel pipes according to the table, where this parameter has already been calculated according to the standard;

- perform the calculation of 1 pm pipe according to mathematical formulas.

table 2

| Type of electric-welded pipe (DN / wall thickness) | Theoretical specific gravity, kg |

| 1620x20 | 789,17 |

| 1320x9 | 290,98 |

| 720x8 | 140,47 |

| 1120x16 | 435,62 |

| 1620x14 | 554,48 |

| 820x19 | 375,32 |

| 1220x20 | 542,55 |

| 720x12 | 209,52 |

| 1420x18 | 622,36 |

| 1120x10 | 273,74 |

| 720x19 | 328,47 |

| 1620x16 | 632,91 |

| 1320x20 | 641,20 |

| 920x8 | 179,93 |

| 1520x10 | 372,39 |

| 820x14 | 278,28 |

| 1220x10 | 298,4 |

| 1320x14 | 450,91 |

| 920x10 | 224,42 |

| 1620x16 | 632,91 |

| 920x7 | 157,61 |

| 720x7 | 123,08 |

| 1420x12 | 416,68 |

| 219x5 | 26,39 |

| 325x7 | 54,9 |

It is important to understand that both methods can give only an approximate answer to how much 1 p m of electric-welded pipe weighs. This is due to the following factors:

- There are many grades of steel, which, as a rule, differ in density from the established standard (7850 kg / m3). When calculating the total weight of a large batch, the error can be quite noticeable;

- As a rule, the calculation data used determine the shape of the pipe as geometrically ideal, without taking into account the fact that the wall thickness cannot be the same along the entire length of the product. Each product has rounding in the corners, as well as the influx of metal on the weld. And also there are some permissible deviations in the size of the pipes, which are not always possible to make in the calculation formula.

- and it is also worth noting that during calculations it is often necessary to round off the obtained values, which affects the final result.

Any pipe may have deviations in wall thickness along its entire length, but this error cannot be calculated and taken into account in the mathematical definition of weight

It is recommended to determine the specific gravity of longitudinally welded pipes, as well as other types of rolled metal using special tables. As a rule, when compiling them, rather complex calculations using mathematical formulas are used, which allow you to determine the most accurate values of specific gravity.

Table 3

| Type of electric-welded pipe (DN / wall thickness) | Theoretical specific gravity, kg |

| 102x3.5 | 8,5 |

| 219x7 | 36,6 |

| 377x10 | 90,51 |

| 108x3.5 | 9,02 |

| 426x6 | 62,15 |

| 219x6 | 31,52 |

| 377x8 | 72,8 |

| 159x7 | 26,24 |

| 114x4.5 | 12,15 |

| 325x9 | 70,14 |

| 133x5 | 15,78 |

| 325x8 | 62,54 |

| 273x7 | 45,92 |

| 133x4 | 12,73 |

| 89x4 | 8,83 |

| 159x8 | 29,79 |

| 273x5 | 33,05 |

| 127x3 | 9,17 |

| 530x10 | 128,2 |

| 133x4.5 | 14,26 |

| 76x3 | 5,4 |

| 273x6 | 39,51 |

| 108x5 | 12,7 |

| 530x8 | 103,0 |

| 114x4 | 10,85 |

| 159x4.5 | 17,15 |

| 89x3 | 6,36 |

| 273x9 | 58,6 |

| 530x6 | 77,54 |

| 108x3 | 7,77 |

| 219x4.5 | 23,8 |

In order to use this method, you must first find out the type of product, the weight of which must be calculated. After the type of pipes is determined, a table is found in the network that corresponds to this type of metal product. In addition, you can find information according to GOST on the products you are interested in. For example, for steel straight-seam electric-welded pipes with a circular cross-section, it is necessary to search for GOST 10704–91.

The second stage in determining the specific gravity includes a search for the products of interest to you in table No. 4.

Tip! If the table did not contain accurate data for a specific product (cross-sectional index and wall thickness), it is recommended to select the closest possible value.

Table 4

|

Type of electric-welded pipe (DN / wall thickness) |

Theoretical specific gravity, kg |

| 1520x14 | 519,96 |

| 1120x17 | 462,43 |

| 820x9 | 180 |

| 920x20 | 443,91 |

| 1620x12 | 475,87 |

| 1220x14 | 416,38 |

| 1520x11 | 409,36 |

| 720x10 | 175,1 |

| 1220x9 | 268,79 |

| 820x8 | 160,2 |

| 1120x14 | 381,86 |

| 1620x10 | 397,05 |

| 920x16 | 356,7 |

| 1420x19 | 656,46 |

| 1220x20 | 591,87 |

| 820x7 | 140,35 |

| 1420x10 | 347,73 |

| 1120x9 | 246,59 |

| 1320x19 | 609,61 |

| 920x14 | 312,81 |

| 1520x18 | 666,75 |

| 1320x12 | 387,09 |

| 820x20 | 394,58 |

| 1320x16 | 514,54 |

| 1420x20 | 690,52 |

| 1120x8 | 219,39 |

| 920x9 | 202,2 |

The method, which involves finding the required value in the table, is considered the most simple and convenient, since for this you do not need to conduct independent calculations. However, this method implies the presence of the Internet or specialized literature on this topic. In the event that it is not possible to determine the specific gravity of metal products using tables, it is necessary to independently calculate this value.

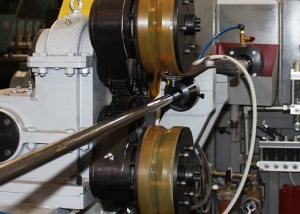

Welded pipes are made from steel strips - strip, and you can try to calculate all the finished product based on the amount of steel taken for production

How to calculate the specific gravity of the pipe by the formulas?

The calculation of the specific gravity of electric-welded pipes according to the formulas is based on the calculation of the volume of steel that went into the execution of 1 m of a pipe. After a volume of 1 m of steel is obtained, it is necessary to multiply this value by the density standard (7850 kg / m3). In case it is necessary to make an independent calculation of the volume, the following sequence of actions is used:

- First, it is necessary to calculate the volume of 1 m of the pipe according to its geometric parameters. To do this, you need to calculate the area of the part and multiply the resulting number by the length of the pipe (1 m).

- Next, you need to calculate the volume of the hollow section, which has the same length (1 m). First of all, in order to perform such an operation, it is necessary to calculate the dimensions of the cavity. The dimensions of the cavity are determined as follows:

- for round pipes, the internal section indicators are obtained as follows: it is necessary to subtract the external section indicator from the doubled wall thickness indicator.

- for a profile (rectangular or square pipe), the index of the internal section is determined in the same way.

After the cavity size is calculated, it is necessary to perform the same calculations as in paragraph 1.

- At the last stage, it is required from the first, received number, to take away the second. Thus, you get the finished volume of the product.

After receiving the volume, you can take additional measurements from metal products.

Important! All calculations should be made in meters and kilograms, so if you have measurements in centimeters, then you need to translate them into meters in this way: 1 cm = 0.1 m, and when in millimeters - 1 mm = 0.001 m.

The calculation of the volume of products with a round cross-sectional shape is carried out according to a special formula:

V = R × R × π × L,

where V is the volume measured in m³; R is the radius, which is half the diameter of the part, m; π is the number Pi (constant value, which is 3.14); L - length, m.

In addition, there is another formula by which it is possible to calculate the weight of 1 p m of steel electric-welded pipes:

Weight = π × (D - T) × T × L × P,

where π is the Pi number (constant, which is 3.14); D is an indicator of the outer section, m; T is an indicator of the wall thickness of the steel part, m; L is the length of the part, m; P - density indicator of steel product, kg / m³.

Each of the methods for determining the weight of 1 m pipe may be suitable for a particular case, however, it is recommended to determine this indicator from the table. This is due to the fact that in the calculations you can easily make a mistake and display a completely wrong number. An error in the calculations entails many problems, so it is better to find the specific gravity of the products you are interested in in the table, even if this indicator is approximate.