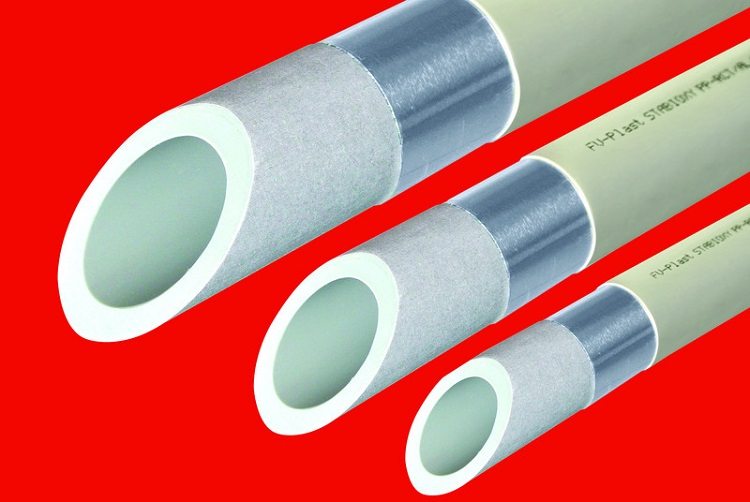

The advantages of polypropylene pipes led to their high demand in the segment of sanitary products in the world market. However, it was not without drawbacks. In particular, they have a high linear expansion coefficient. Therefore, the factories mastered the production of products reinforced with a reinforcing layer. They are used for heating and water supply systems. Particularly popular at the moment aluminum reinforced polypropylene pipes.

Content

Polypropylene pipe properties

These products are highly resistant to chemically aggressive compounds and exhibit a very long service life. They are characterized by the absence of:

- corrosion plaque;

- rust;

- calcareous deposits;

- decay.

An important factor determining the popularity is the invariability of their diameter, and, accordingly, the stability of the throughput of the pipeline as a whole. And, of course, not the least role is played by the fact that, throughout the operation of polypropylene pipes, their inner surface remains almost smooth. Such products are prone to sagging in winter. However, the use of thermal insulation for polypropylene pipes partially solves this problem.

Depending on the manufacturing technology, polypropylene pipes can withstand various pressures. According to this criterion, they are divided into several types.

PN10. This is a thin pipe with a life of about 50 years. It is used in cold water supply systems. Nominal pressure up to 1 MPa.

PPR pipes come in different diameters: the thinnest are suitable for systems with a low temperature of the transported liquid

Standard sizes of polypropylene pipes are presented in the table.

Table 1

| Wall thickness mm | 1,90-10 |

| Outer diameter mm | 20-110 |

| Inner diameter mm | 16,2-90 |

Helpful information! On the basis of PN10 pipes, it is allowed to create a “warm floor” with a coolant temperature not exceeding + 45 ° C.

PN20. Pipes of this category are used for hot (coolant temperature up to + 80˚С) and cold water supply in industrial and residential buildings. Nominal pressure - up to 2 MPa. Service life - about 25 years.

Below are the standard geometric characteristics of PN20 polypropylene pipes.

table 2

| Wall thickness mm | 16-18,40 |

| Outer diameter mm | 16-110 |

| Inner diameter mm | 10,60-73,20 |

PN25. This group includes products reinforced with aluminum. They are used in the installation of hot water supply and heating systems. Nominal pressure - up to 2.50 MPa. Such a pipe is suitable for concealed and open installation, indoors and outdoors.

The standard sizes of PN25 polypropylene pipes are presented below.

Table 3

| Wall thickness mm | 4-13,4 |

| Outer diameter mm | 21,2-77,9 |

| Inner diameter mm | 13,2-50 |

Compared to metal, polypropylene pipes have two serious drawbacks. It:

- Increased oxygen permeability.

- High coefficient of thermal linear expansion.

But reinforcing polypropylene structures solves these problems.

Features of aluminum-reinforced polypropylene pipe

Reinforcement of polypropylene gives the final product the following positive characteristics:

- contact with an overheated medium does not cause loss of stiffness. The body of an unreinforced polypropylene pipe when transported under pressure from an overheated medium can simply collapse. By the way, that is why products of this type are not used in hot water supply;

- starting material becomes less ductile. High elasticity of polypropylene is not significant in open systems. However, an uncontrollable increase in the dimensions of a pipe mounted in a solid ceiling of a wall or floor when liquid enters its cavity can cause cracking on the supporting surface. And due to the presence of a rigid frame in the polypropylene reinforced pipe, no deformation will occur.

These products can be used to create heating systems: such a pipe will not begin to swell at a temperature of + 120 ° C. In this case, the allowable limit value approaches 175 ° C.

Moreover, even such extreme heating will cause only a loss of stiffness, as a result of which the pipe will sag, but its integrity will be preserved.

Reinforced pipes do not sag under the influence of temperature and the system functions without failures

Advice! The above are data from experiments performed in laboratory conditions. In practice, it is better to avoid transporting liquids with temperatures exceeding + 95 ° C.

However, from the point of view of the possibility of operation in "hot" water pipes and heating systems for polypropylene pipes reinforced with aluminum, this restriction is not critical. Indeed, even water heated in the boiler to + 100 ° C "on the way" loses heat and enters these utilities with a temperature of the order of + 95 ° C.

Reinforcement Methods

Most often, reinforcement of polypropylene pipes is carried out in such a way that the edges of the aluminum foil are overlapped. Although many domestic manufacturers have adopted this technology, welding of the edges of the foil end-to-end with a laser has also received sufficient development today. This design ensures the absence of contact of the coolant with the reinforcing layer. In this case, welding of the pipe joint and fitting remains consistently high quality.

At the initial stage of development of this technology, the reinforcement was carried out by a continuous aluminum foil, which prevented oxygen from entering the coolant and imparted exceptional smoothness to the outer surface of the pipe. But at the same time, serious difficulties arose with fixing the foil to the polypropylene layers. In this regard, in the production of aluminum-reinforced pipes, special requirements are imposed on the quality of the glue and on the humidity and temperature conditions.

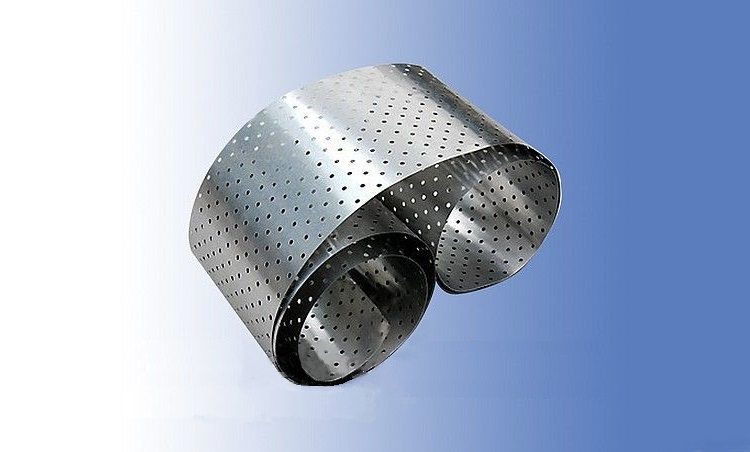

The use of perforated aluminum foil in PP pipes reduces the risk of pipe deformation due to condensate

The above method of manufacturing this product has another drawback. Polypropylene is hygroscopic, therefore moisture penetrates through its walls into the structure, but it cannot pass beyond the foil layer. As a result of its accumulation on the surface layer, unnecessary swelling is formed.

To exclude this phenomenon, today aluminum foil with perforation is used for reinforcement. That is, round its holes are evenly distributed over its entire surface. This method provides strong bonding between a decorative and base polymer layers over the entire area of the product. Manufacturers guarantee that the performance characteristics of an aluminum-reinforced polypropylene pipe obtained by this technology will ensure the service life of structures with cold water 50 and 25 years with hot water.

Is reinforced polypropylene pipe insulated?

This question is quite natural. After all, polypropylene is not susceptible to corrosion. This, in fact, is the main advantage of pipes made from it compared to metal products. However, in the case of external piping, insulation is also needed. Due to her:

- the level of heat loss in the cold season decreases. Engineering communications are laid in the open air, and not just indoors. Therefore, without insulation for polypropylene pipes, including those reinforced with aluminum, most of the heat on the way to the destination will simply disappear;

- condensate cooling. This applies to cold water. On the surface of products of this type in comparison with their steel "colleagues", condensate also forms, but in a smaller volume.

Important! When slight precipitation is observed, temperature differences can also cause this phenomenon. Therefore, thermal protection is needed in any case.

The list of products for the insulation of polypropylene pipes reinforced with aluminum is the same as for ordinary products. These are the following materials:

- glass wool. Such a heater is the most affordable. Glass wool is not afraid of either high temperatures or fire. Moreover, it has good warming characteristics;

- foamed polyethylene. Most often made in the form of a sleeve with a one-sided cut. Many of our compatriots prefer this insulation for polypropylene pipes due to the ease of installation;

- polystyrene foam (polystyrene). Due to the low thermal conductivity, experts consider it one of the most effective heaters;

- polyurethane foam. In appearance, it resembles a traditional polystyrene foam, but differs in the structure of the cells. On sale is most often present in the form of shells.

Aluminum-reinforced polypropylene pipes are in high demand due to their exceptional qualities and characteristics. The right choice and competent installation save you from problems during the entire period of their operation.