Any type of steel products is designed for specific operating conditions. Large-diameter steel pipes are indispensable in many industries, including laying communications under highways and bridges, in agriculture and industrial production. Wide billets are used less often than products with a small cross section, but small diameter pipes are not suitable for various technical tasks, where a large clearance and impressive throughput are needed.

Content

Basic standardization of large pipes

Large diameter pipes are available in various materials:

- Metals

- Polymers

Diameter is a significant indicator of the size of a steel tubular product, and it is crucial when choosing products for special operating conditions. Along with the thickness of the walls and the width of the clearance, this is the most important characteristic for determining their purpose.

The standardization of the diameters of ferrous metal pipes is regulated by the standards of GOST 10704-91, where the main classification of products is outlined:

- medium diameter (from 114 to 530 mm);

- steel tubes of small diameter (within 114mm);

- large diameter (over 508mm).

According to TU and GOST, other indicators are also stipulated and spelled out in tables:

- Outside diameter (determines the dimensions).

- Inner diameter (clearance).

- Wall thickness.

- The nominal and nominal diameters that determine the main product range, pipe throughput and their weight.

Products also include:

- seamless (solid);

- welded (with a seam made from rolled sheets).

The first, more expensive, are designed for increased pressure and a large external load. The second are for normal conditions. In turn, pipes are:

- thin-walled;

- thick-walled;

- standard.

According to the method of production, hot-rolled products and models of cold deformation are distinguished. For their manufacture, steel of various grades is used.

Note! GOST standards take into account significant deviations in the wall thickness of the LDP (large diameter pipes). A product with a wall thickness of 8-12 mm often has deviations of up to 0.7-0.8 mm in the smaller and larger directions. This affects the total weight, which is taken into account in large batches when shipped to customers. Because of this, inconsistencies indicated in the documents and the actual thickness of the pipe, the parameters of which were measured during verification, are possible.

For most products, the mass is calculated taking into account the density of steel - 7.85 g / cm, with deviations of no more than 8%. The weight of the pipes is affected by the diameter, length of the product and wall thickness.

In the tables, which indicate the range of products from metal, the price is indicated for 1 ton of pipe of large diameters, and not based on calculations for 1 linear meter. Accurate and quick calculations of the mass of the purchased batch are made according to a special program or according to the "calculator" of the official website of the enterprise. If the parameters are in inches (imported products), use the special tables to convert the sizes.

Corrosion-resistant coating is another important characteristic in the production of pipes and the selection of products for various purposes. Galvanization or other coating is applied:

- outside;

- inside;

- at both sides.

Important! The main parameters are used to determine all pipe diameters indicated in the GOST tables. TU (technical conditions) regulate the possibilities for the production of special products.

Purpose of pipes of different diameters

The most common type of metal products is steel pipes of different sections. They are released with a lumen of various shapes, mostly round. The diameter determines the purpose of the products.

1. Metal pipes of small and small diameter:

- cable protection from damage;

- water pipe laying;

- heating system;

- gas pipeline;

- steam line.

2. Pipes within 273 mm - 325 mm:

- for the oil and gas industry;

- water supply

- energy and gas transportation;

- communications of all varieties;

- chemical industry;

- utilities;

- heating plants and boiler rooms.

3. Steel pipes within 426 mm - 530 mm are used in the same sectors of the national economy and in the industrial sphere, but when a pipeline with a higher throughput is required. They are also used for the construction of various structures - as a frame or supports.

4. Products of large diameter among the most common pipes, their use in various fields:

- industry and heavy machinery;

- heating plants;

- bridge building (supports);

- shipbuilding;

- drainage and sewage;

- road construction;

- drill holes, etc.

5. Pipes of large diameters (within 720 mm - 1020 mm):

- high bandwidth communications;

- trunk oil pipelines;

- gas transportation over long distances;

- large construction sites.

6. The largest pipes (1420mm - 2020mm) are products for underground use that are reliably protected against corrosion by a special coating:

- large volume water supply systems, including wells, drains and sewage;

- tunnels and hidden river beds under the highway.

Work with pipes of large diameters requires the use of equipment for their transportation, loading and movement

What is important to know about large pipes

Large-diameter metal pipes are a common type of product that rolling mills produce. Demand is explained by a wide scope.

It is interesting! The only drawback of large pipes is the difficulty of installation due to cutting and welding. LDPs do not bend, turning sections are most difficult to lay, especially in underground and underwater sections of the main pipeline.

The end surface of a large pipe is treated differently:

- with the processing of burrs after trimming at the ends;

- during the manufacture of burrs it does not form, but there are irregularities removed by additional trimming for better matching.

Classification of LDP for its intended purpose:

- large diameter steel pipes for general use;

- special purpose products.

There is also a classification according to the type of workpiece welding:

- Straight-seam parts, where the rolled sheets are connected by contact welding, their size across is within 426 mm.

- Long-seam products manufactured using electric arc welding - within 820 mm.

- Straight-seam steel products connected by electric arc welding are produced in sizes from 530 mm to 820 mm.

The strength of large pipes allows them to be used for underground installation in places with a high load on the ground

There is no doubt in the reliability of the seam, since it is tested along its entire length with special equipment. Welded pipes are excellent for general communications and construction.

Whole products are designed for impressive gas pressure. In the standardization tables, LDPs are presented with a diameter of 530 mm, 630 mm, 720 mm, 820 mm, 1020 mm, 1220 mm, 1420 mm, 1620 mm (and more). Large metal tubes are in demand not only in the industrial production of oil and gas, but also among construction firms. The length of large products of measured length varies within 11.5 m.

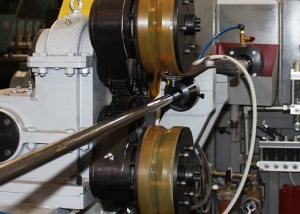

The industrial production of LDP with a welded seam covers 5 stages:

- Cutting rolled into sheets.

- Folding blanks in a vicious circle (another shape is possible).

- Butt welding by a specific method.

- Edge processing.

- Seam quality testing.

To establish the production of small and large diameter pipes, the technologist must comply with GOST standards to confirm all the requirements for certified products. Release technology provides:

- high quality products;

- stiffness and stable shape;

- strength and durability;

- resistance to mechanical stress;

- ability to withstand impressive internal and external pressure

The minimum life of steel LDP is 10-12 years, with corrosion protection - up to 35-40 years.

The insulating layer applied to pipes in an industrial way reduces heat loss when using pipes in heating mains

Different types of insulation are applied to the LDP intended for transporting the coolant - PPU, TsPI, VUS. This helps maintain the temperature of the water along the entire length of the heating main.

Tables of sizes of steel pipes of large diameter and legend

The standardization of rolled products facilitates the design calculations and the selection of products for gas pipelines or structures of any type. The diameter, length and weight of the LDP are specified by GOST standards and are indicated in the assortment tables. The most important quantities are noted in them:

- conditional diameter (Du, Dy - rounded value in millimeters or inches);

- nominal diameter (Dn Dn), the main value, which can vary with slight deviations;

- outer diameter (maximum indicator of pipes of small, medium and large sizes);

- inner diameter (taken into account when connecting the pipeline);

- wall thickness (defines thin-walled, standard and thick-walled products).

Marking of finished products also contains letter designations:

- Dy - conditional pass (in mm or inches);

- G is the cross section of the thread;

- Dh is the outer or outer dimension across.

Note! Dimensions in inches indicate a double stroke - 2 ″, in their shares - 1/2 ″ or 3/4 ″. The translation of values is also carried out according to the tables, 1 inch - about 2.54 cm.

Large diameter steel pipes are used for pipelines with large and increased throughput. Their application is not limited to this; they are in demand for the construction of underground highways and a hidden river bed under bridges under construction. LDPs are capable of ensuring uninterrupted supplies of substances of different consistencies over long distances. Large pipes withstand the high internal pressure of the transported gaseous medium and impressive external mechanical loads.