Rolling of copper pipes is a deformation of their walls in a given direction. The need for it often arises during water supply installation and installation of air conditioners. In industry, flaring involves rolling pipes through rollers, which give the corresponding shape. At home, this operation is performed using a special tool. It is called rolling for copper pipes.

Content

Types of devices for flaring

To choose the necessary profile and connecting elements on the market is not particularly difficult today. However, do-it-yourself flaring of copper tubes at home is sometimes unavoidable. There is no alternative if:

- industry does not produce products of the required form:

- buy at the moment necessary fitting does not seem possible;

- it is necessary to make an accurate fit of the product.

The simplest bearer for copper pipes is a conical shape template. It is inserted into the pipe and cranked until the desired result is achieved. The main disadvantages of using such a tool are the inability to control the accuracy of the fit and the high probability of wall deformation where they should be straightforward.

Important! Home-made flaring for copper pipes can be used only in a single case, since there is a risk of their incorrect processing. Do-it-yourself tools are not allowed when installing water, cooling and air conditioning systems.

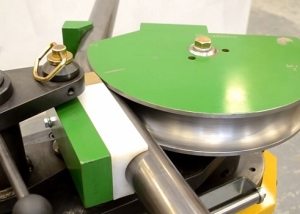

On sale you can find special equipment for flaring. These are electrical and mechanical devices. With their help, radial deformation of the copper pipe is performed, which allows you to create a press connection of the pipeline elements. The acceleration of the laying of the copper pipe of the engineering system allows the combination in one design of an electric tool for expanding copper pipes with a pipe bender.

Copper is highly treatable. Knowing this, many home masters strive to quickly perform installation work with the help of cheaper equipment ˗ templates. However, experts recommend abandoning such devices. They explain this by the fact that the electric and mechanical tools during expansion carry out the deformation carefully, the surface remains smooth, the wall thickness is the same, and the material retains the uniformity of the structure, while it is impossible to achieve such results with the template.

In the design of the simplest flare makers, there are no ratchets and eccentrics. Therefore, their use often leads to the fact that the surface of the pipe is not smooth enough. And in order to give its edge a neat appearance, it is necessary to use an additional tool.

It is worth studying the features of the work of eccentric flaring for copper pipes. The design of this model determines a slightly different principle of its action. It also has a cone, but it is not pressed into the pipe, but gradually smooths and expands its walls, making rotational movements.Such a tool is perhaps the most perfect expansion, because even if initially the thickness of the pipe walls along its perimeter was different, the value of this parameter for the final product will be the same.

Important! Even knowing how to make a copper pipe with your own hands, use only a tool specially created for this. Otherwise, when expanding the diameter, you may encounter a rupture of the product and a heterogeneity of deformation. And these factors can provoke leaks in the future, and, in general, reduce the shelf life of the pipeline.

What we pay attention to when buying a tool. Leading brands

When choosing flaring for copper pipes, pay attention to those indicators, due to which the reliability of the connection will be ensured, and the pipe itself will remain intact. The main ones are as follows:

- diameter and number of calibrated holes:

- the height of the protrusion of the pipe;

- diameter of a copper pipe (external and internal);

- pipe wall thickness;

- depth of necessary flaring;

- perforation step. By such is meant the remoteness of the centers of the holes;

- the presence or absence of grooves, as well as welds.

The price of a flare-maker depends, first of all, on its quality, equipment, as well as the principle of operation and varies in the average price range. The purchase of an expensive professional tool will pay off only if you plan to engage in the installation of copper pipelines constantly. For a one-time do-it-yourself arrangement of your own engineering communications highway, a minimally decent one will do. When choosing, give preference to milling machines that have rolled off the assembly lines of such companies as BRITOOL (Great Britain), USAG, KAPRIOL, BETA (Italy), WERA, HAZET, WITTE, GEDORE (Germany).

DIY flared pipe connection

Today, two methods are used for this: soldering and pipe coupling. The chosen method affects the sequence of actions.

Coupling connection. In this case, the sequence of actions is as follows:

- Thoroughly strip the pipe edge.

- Put the sleeve on the pipe end.

- Next, “connect” the flare maker to work. Insert the prepared pipe into it and turn the tool screw until the bend of the pipe edge reaches 45 не.

- Finally, remove the pipe from the flare and connect it to the other pipe segment using a sleeve.

Important! Inexperienced home masters, and even more so for beginners, experts recommend using a pipe coupling after expansion.

Solder connection. When you plan to apply this connection method, the following work will be done:

- First you need to carefully clean the pipe edge. This is done using a special brush.

- Then insert the pipe into the flare. Extend the edges of the pipe so that you can insert another pipe into it under certain conditions. This condition says: between the outer surface of the inserted pipe and the inner surface of the other, there must be some, even a small, gap.

- Apply flux to the pipe placed inside, then insert it into the mating flared pipe. There is one more condition: the insertion depth must be equal to the diameter of the pipe.

- Next, use a soldering iron or a gas burner to warm up the junction of the two pipes. The solder should melt and completely fill the gap between the surfaces of these elements of the future pipeline.

- Then place the already connected pipes on a flat horizontal surface, and wait until they cool to ambient temperature. Only after that it will be possible to work with this segment of the pipeline.

When choosing a tool for expansion, it is necessary to take into account the diameters of the pipes with which you will have to work. For water mains, products with the value of this parameter are usually used. If the heating system is installed in a private house, then, depending on the model of the boiler, the optimal cross-section varies in the range 32 ... 40 mm. At installation of conditioners products with a diameter up to 16 mm are used. In addition, it is necessary to be guided by the following criteria: the possibility of using replaceable nozzles for pipes of various sections and the quality of the resulting bell. This approach will provide convenience in work and reliability of the future connection.