Not everyone knows that at present there are many types of polypropylene pipes that differ in technical characteristics, quality, purpose and color. But these products are increasingly being used to equip home water supply networks, and, in fact, replaced steel analogues. On their basis, it is possible to create engineering communications with an elevated temperature of the working environment - hot water supply and heating systems.

Content

Labeling of polypropylene pipes

The first thing you need to pay attention to when choosing these products is what labeling they have. The fact is that the technical characteristics of polypropylene pipes differ from modification to modification. And this factor imposes significant restrictions on the scope of their application. In particular, not all of them are capable of operating at significant pressure and high temperature.

Existing Standard Classification polypropylene pipes subdivides such products into 4 groups. Their designation contains Latin letters PN and two digits. This number indicates what pressure the polypropylene pipes are designed for.

PN10. Systems assembled on the basis of the products of this https://pipe.expertexpro.com/en/vodoprovodnye/prokladka-polipropilenovyx-trub.html group withstand pressure up to 10 atmospheres. The answer to the question regarding the maximum temperature of the working medium is unambiguous: + 45˚С. These numbers are indicated on the surface of the pipes. Using pipe products of this type, communications are created for transporting only cold liquids. The main difference is thin walls. “Due to” such technical characteristics, PN10 polypropylene pipes have not been widely used for pipeline laying in apartments.

PN16. Polypropylene pipes, indicated by such a sequence of characters, withstand pressure up to 16 atmospheres, it is possible to transport liquid with a temperature of + 60 ° C through them. These polypropylene pipes can be selected exclusively for “cold” lines. In addition, they have a sufficiently high coefficient of temperature deformation, which is unacceptable in pressure pipelines of heating and hot water supply.

PN20. What pressure the polypropylene pipe can withstand, in the designation of which there is such a combination of symbols, we already know - 20 atmospheres. And the temperature of the water is + 95 неС they are not afraid. Technical characteristics of PN20 polypropylene pipes allow their use in hot water supply.

Important! Due to significant temperature deformation in pressure heating systems, they are not currently used. When a liquid is transported through such a pipe under high pressure with a temperature approaching the maximum allowable, it leads and bends.

PN25. These are already full-fledged pipes for heating from polypropylene. The temperature of the coolant can reach + 95˚С. The answer to the question, what pressure does a PN25 polypropylene pipe hold, is clear - 25 atmospheres. As a raw material for their manufacture, a composite material with reinforcing inserts is used. These may be nylon fiber or aluminum foil. Both types of interlayer not only improve the strength characteristics of polypropylene pipes, but also reduce thermal deformation.Even when transporting water with a maximum permissible temperature under high pressure, their linear dimensions will not change. Therefore, reinforced products are widely used in pressure pipelines. Another important factor: in comparison with a thick-walled polypropylene pipe installed in similar highways, the heat loss in metal-plastic products is two times lower. But in terms of frost resistance, these types of pipes are comparable.

Pros and cons of polypropylene pipes

The technical characteristics of the polypropylene pipe, which made it one of the most popular types of building materials, are due to the amazing properties of this polymer.

One of the advantages of polypropylene pipes is installation: with a fairly simple technology, a strong and durable connection is obtained

What features of polypropylene pipes do experts highlight? There are several of them:

- service life of about 50 years. And when used only in cold water supply, according to manufacturers, - all 100;

- prevent the formation of solid deposits. This characteristic of polypropylene pipes is due to the use of a special technology for processing the inner surface at the production stage;

- sound insulation. This property is inherent even in a polypropylene pressure pipe, in which the movement of a liquid under high pressure can cause vibrating and rumbling noises unpleasant for the human ear;

- lack of condensate. This is due to the low thermal conductivity of polypropylene pipes;

- low weight. The value of this characteristic of a polypropylene pipe is 9 times less than the value of a similar parameter of a metal product;

- ease mounting. But if this is your first time doing this, you should heed the advice of professionals. In particular, pay special attention to the heating time of polypropylene pipes when they are connected by welding;

- do not need additional maintenance;

- resistant to chemically aggressive acid-base compounds;

- high elasticity;

- affordable cost. You can choose such products in any price range.

An important role in the high demand taking into account the peculiarities of the climate of our country is played by the frost resistance of polypropylene pipes, due to their low thermal conductivity.

Polypropylene pipes are resistant to low temperatures, and no special conditions are required for their storage and operation.

The advantages of polypropylene pipes were indicated above. But, as always, it can’t do without minuses here either. The main ones are:

- Fairly high linear expansion. Non-reinforced polypropylene pipes during installation require the use of special compensators.

- Low temperature resistance. Regardless of which polypropylene pipes are selected, it is necessary to immediately find a heater. This is especially true for heating systems.

- Poor deformation ability. It is impossible to change the direction of the pipe without the use of additional fittings.

- Weak resistance to direct sunlight. Although reaching the maximum temperature for polypropylene pipes this phenomenon does not cause, but it is accompanied by premature accelerated aging of the material.

Advice! Considering the expansion factor, when installing the pipeline, follow the special installation rules. In particular, do not allow pipes to sag - for this you need to locate the pipe attachment points on the wall at small intervals.

How to choose polypropylene pipes

For the correct selection of these products, five points must be taken into account. Labeling of polypropylene pipes has already been discussed, so 4 important factors remain.

Maximum temperature. The choice should be made based on the expected value of this parameter of the coolant, taking into account the labeling of polypropylene pipes.As mentioned above, PN25 is the best choice for heating systems, PN20 is for hot water supply, PN16 is for cold water supply systems.

Diameter. It is necessary to select it taking into account the technical characteristics of the created pipeline system. The best polypropylene pipes for apartment wiring are considered products with a diameter of 20 and 25 millimeters. For risers, it is better to use products with a cross section of 32 or 40 millimeters. A thick-walled polypropylene pipe of large diameter is used for the main pipeline mounted in the basement of an apartment building.

Maximum allowable pressure. If we talk about domestic use, then almost all types of pipes are suitable, including a PN10 product. How their service life is related to pressure and temperature, we will consider this pipe as an example.

- water temperature 20˚С. The service life will be at least 50 years if the pressure in the central line does not exceed the mark in

- water temperature 50˚С. In this case, in order for the service life to be 50 years, it is necessary to withstand pressure not exceeding;

- water temperature 70˚С. The service life will be equal to that declared by the manufacturer at pressure;

- the water temperature is kept at 95˚C for a long time. In this case, a service life of 50 years is out of the question. The maximum is some 5 years at constant pressure.

Coefficient of thermal expansion. We already know that polypropylene pipes are such products whose geometry changes at high temperature of the transported liquid. The changes relate to the thickness of their walls. And this is critical for such a parameter as pipeline throughput.

Pipe type PN20 closed is not recommended. After all, its deformation can cause cracks in the layer of plaster. But the use of polypropylene pipes of type PN25 allows laying both closed and open. In the latter case, the interior of the living room will not deteriorate due to the lack of bending of these products. After all reinforced polypropylene pipe keeps its shape perfectly.

Important! The characteristic of polypropylene pipes “Linear expansion coefficient” largely determines which method of laying a hot pipeline should be chosen.

As for the service life of polypropylene pipes, if used correctly, each of them will last at least five decades.

Water pipes laid inside the walls will not spoil the look and style of the bathroom, but for this method of laying, you need to choose durable pipes

Assortment of polypropylene pipes

This segment of the world market is represented by the following varieties of polypropylene pipes:

- PPH. These are the simplest polypropylene products and all those that only modern industry produces. They are designed to create cold water supply systems, industrial pipelines, as well as ventilation systems;

- PPB Such a variety of rolled stock assortment is made from a complex block copolymer of polypropylene. These products have found application in pressure systems for supplying cold water and heating. But they are used not only as pressure pipes made of polypropylene. High-strength shock connecting elements are made of them;

- PPR For production, random copolymer of polypropylene is used. Based on this variety of pipes, systems are created for both hot and cold water supply, including water heated floors;

- PPs. This is a separate type of tube stock assortment. As a raw material for its manufacture, a highly inflammable high-strength polymer is used. The operating maximum temperature of PPs type polypropylene pipes is + 95 ° C. According to experts, this is the best option for a single-layer (non-reinforced) product for heating systems.

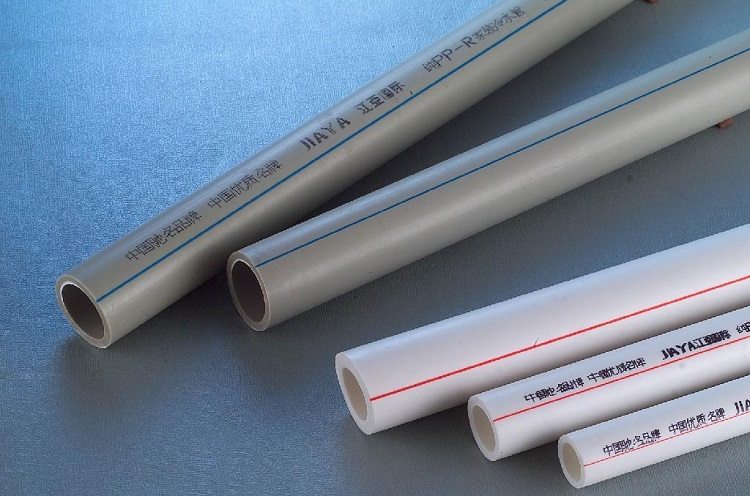

Color polypropylene pipes

The range of polypropylene rolled products is presented in four colors. They are white, gray, black and green. On the basis of white or gray polypropylene pipes, various utilities are mounted, from the water supply system to the individual heating system.

However, the disadvantage of white pipes is the inability to operate in street conditions, since such products are characterized by low frost resistance. Already at a temperature of 0 ° C, the type of polypropylene used for their manufacture begins to crystallize.

Helpful information! White pipes withstand pressure of 25 bar! At the same time, gray polypropylene pipes are characterized by better tolerance of thermal loads.

Gray pipes also have the following advantages:

- the possibility of operation in pressure systems;

- thermal and chemical stability;

- long operational period;

- environmental friendliness;

- tightness.

In addition, gray polypropylene pipes are perfectly connected with a conventional soldering iron.

From an existing data assortment sewage products, as well as drainage systems, it is recommended to use black pipes made of polypropylene. Additives introduced into the raw materials at the production stage increase their technical capabilities. Of the advantages of plastic black pipes, it is worth highlighting:

- resistance to various aggressive environments;

- exposure to UV radiation;

- high strength;

- declared by the manufacturer service life is fully maintained.

Currently, many owners of suburban areas are interested in the question of which polypropylene pipes are the best for irrigation. The answer is clear: green. They are sold at such a low price that gardeners simply can not pay attention to the strength characteristics of these products.

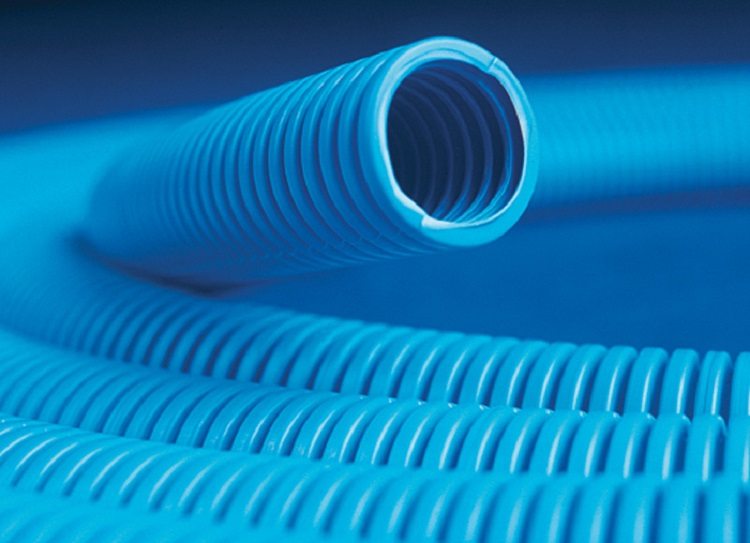

Corrugated pipes made of polypropylene

Such large-diameter products are used for the construction of wastewater, sewage, rainfall (stormwater) and groundwater (drainage) systems.

Corrugated pipes made of polypropylene are used in a variety of fields - a small diameter is in demand for laying electrical networks

The maximum value of the temperature of permanent wastewater assumed for a polypropylene corrugated pipe is of the order of + 60 ° C, and short-term to + 100 ° C., Which is rare. Pipelines are laid that are created on the basis of these products, by trenchless laying and into open trenches, and the organization of crossings is carried out using reinforced concrete wells. Moreover, no other structures, as well as special equipment for laying and installing large diameter corrugated pipes, are required.

Modern enterprises have now mastered the production of double-layer corrugated pipes made of polypropylene. Of their advantages, it is worth highlighting:

- high ring stiffness;

- chemical and corrosion resistance;

- Resist the effects of stray currents. Dielectric properties distinguish these products from metal counterparts. After all, those, being laid close to cable routes, are subject to accelerated aging due to the effects of electrochemical corrosion;

- high throughput;

- increased resistance to waterjet wear;

- long term of operation.

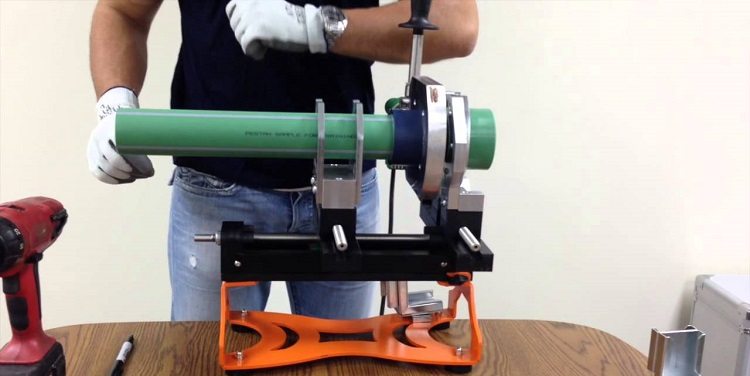

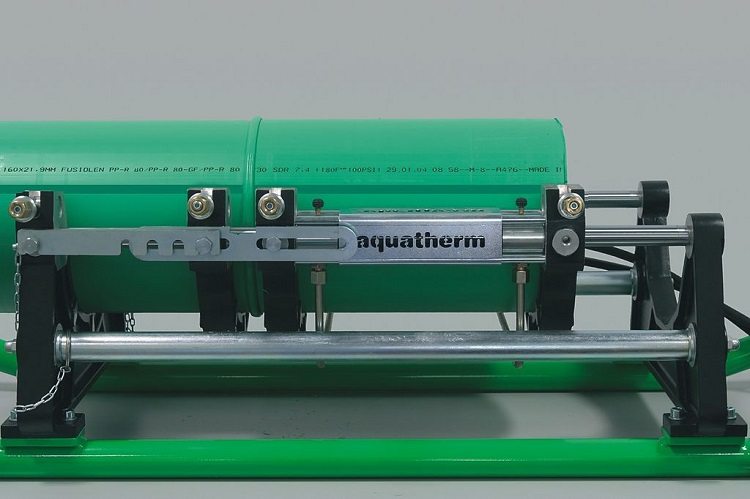

Features of welding polypropylene pipes

For welding products of this type, a thermal polyfusion method is used. It consists in heating the parts to be welded, followed by their quick connection. This procedure is performed using a special soldering iron. Some manufacturers of such instruments equip them immediately with two heating elements, the power of which is enough to heat pipes of a specific diameter. It would seem that this is a plus. But not in this case.

For high-quality pipe joining using the thermal diffusion method, special equipment and strict adherence to welding technology will be required

Important! Heating simultaneously with two elements is able to overheat the plastic and cause an overload of the power supply network. Therefore, the second heater should be used as a spare when the first fails.

Heating time depends on:

- pipe diameter;

- welding belt width;

- ambient temperature. It should not go beyond the norm.

After heating, the material retains ductility for a very short time. In a few seconds you need to have time to fix the connection, while getting rid of distortions. The optimum temperature for heating is considered to be + 260 ° C. To ensure a reliable connection, the pipe material must be warmed up sufficiently. But excessive heat can cause loss of shape. Therefore, you should control the execution time of this operation. Depending on the cross-section of the pipes, it is:

- 8 ... 9 seconds for pipes with a cross section of 20 millimeters;

- 9 ... 10 seconds if pipes with a diameter of 25 millimeters are welded;

- 10 ... 12 seconds when welding pipes with a diameter of 32 mm, etc.

Heated and already connected pipes must be properly cooled. Fixation requires as much time as the heating phase. If you rush and stop this procedure before the expected time, the connection will be deformed. Welding polypropylene pipes is a relatively difficult process. Critical is not only non-observance of the heating time, but also non-compliance with the rules soldering. The main ones are as follows:

- during operation, the welding machine must always be on;

- mandatory marking on the surface of the pipe to ensure the proper depth of the weld.

- the connected elements must be heated at the same time.

Having learned what polypropylene pipes are, most of our compatriots prefer to buy just such products. Invested money will pay off handsomely due to many factors. In particular, the low thermal conductivity of the material allows you to abandon the purchase and installation of thermal insulation. At the same time, heat saving during transportation of the coolant is about 20%. That is, gas consumption in an autonomous heating system can also be reduced.